Stand type LED fluorescent lamp

A technology of LED fluorescent lamps and LED light sources, which is applied to light sources, electric light sources, point light sources, etc., can solve the problems of unsatisfactory local heat dissipation performance, inability to realize multiple lamps in series, and rapid temperature rise of lamp tubes, etc., to prevent the LED temperature from rising. High problem, simple and compact structure, energy saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

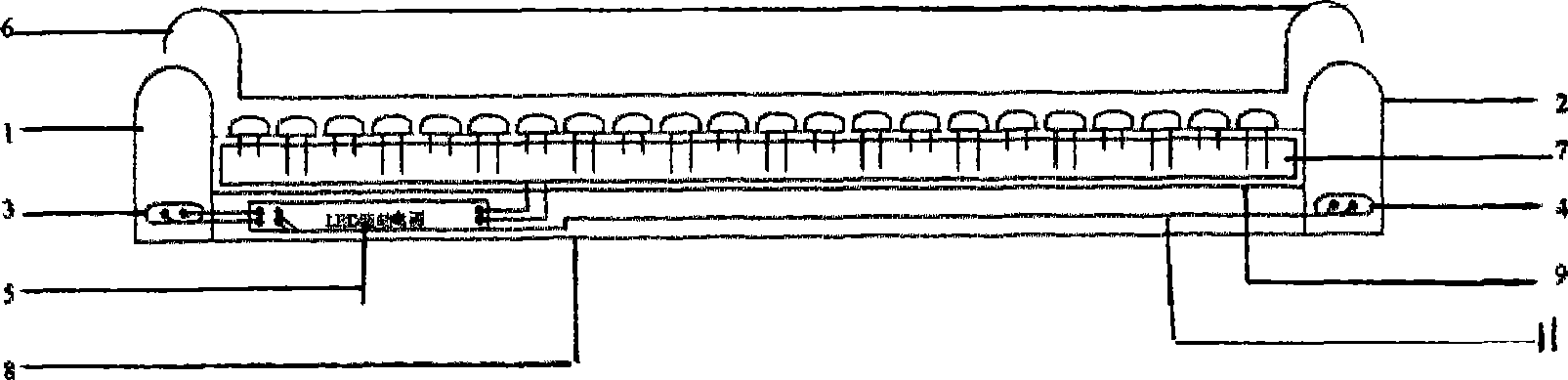

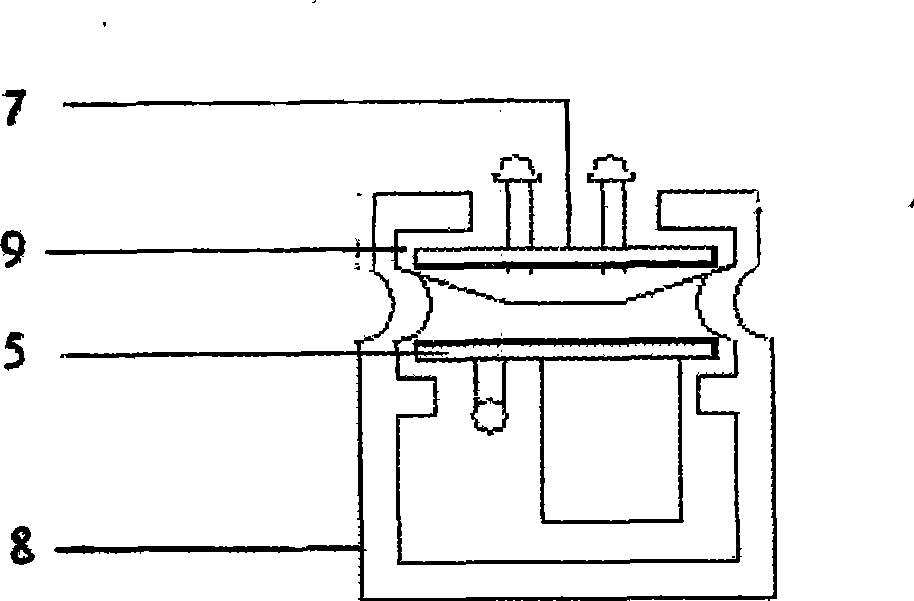

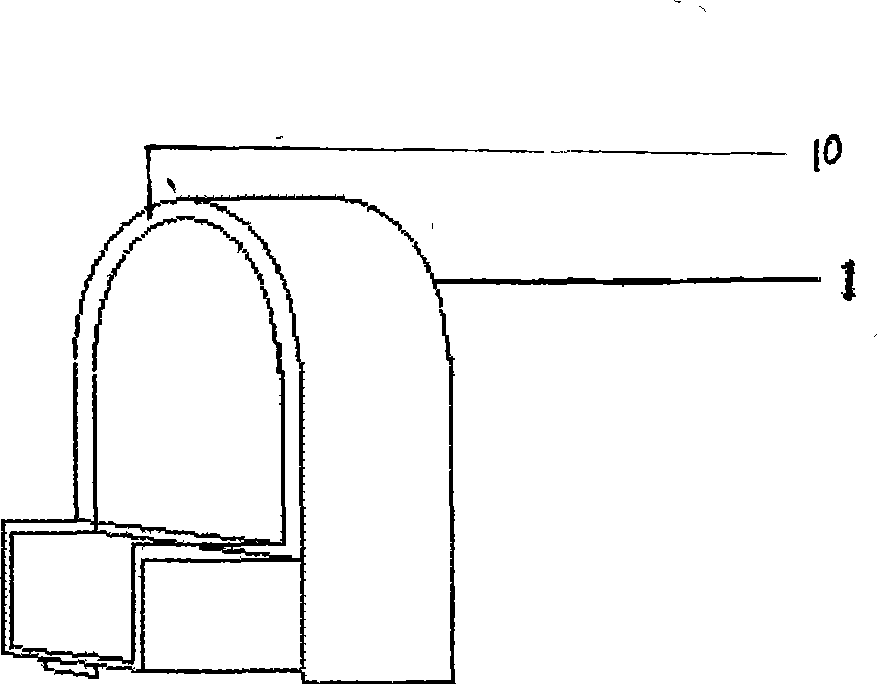

[0019] Example 1, such as figure 1 , figure 2 As shown, the present invention includes a lamp body 8, which is connected to the input and output ends of the bracket and is provided with terminals 1 and 2 of conductive terminals 3 and 4. The lower part of the terminals is provided with a tongue, and the outer diameter of the tongue is consistent with the cavity of the bracket. , so that the two can be plugged together. LED light source circuit board 9, constant current driving power supply (driver) 5, support 8 is a bar-shaped groove body with a boss, and the two walls of the upper part of the bracket seat cavity are provided with LED light source circuit board slots, which are plugged with LED light source circuit board 7 Then, of course, the same purpose can also be achieved by providing parallel bumps on the cavity walls on both sides. The LED light source circuit board is composed of light-emitting diodes and printed circuits on the back of the PCB board. The distance be...

Embodiment 2

[0020] Example 2, such as figure 1 , figure 2 As shown, the present invention includes a lamp body, which is connected to the input and output ends of the bracket and is provided with terminals 1 and 2 of conductive terminals 3. The lower part of the terminals is provided with a tongue, and the outer diameter of the tongue is consistent with the bracket cavity, so that the two plugged in. LED light source circuit board 9, constant current drive power supply (driver) 5, support 8 is the bar-shaped groove body of a band boss, and the side chamber wall on two walls of support base cavity top is provided with parallel salient point, and LED light source circuit board 7 plugging, said LED light source circuit board is made of light-emitting diode and the printed circuit welding of PCB board back side. The distance between the neck of the light-emitting diode on the LED light source circuit board and the top of the PCB is 5mm, that is, the diode feet are exposed to the surface of...

Embodiment 3

[0021] Example 3, such as figure 1 , figure 2 As shown, the present invention includes a lamp body, which is connected to the input and output ends of the bracket and is provided with terminals 1 and 2 of conductive terminals 3. The lower part of the terminals is provided with a tongue, and the outer diameter of the tongue is consistent with the bracket cavity, so that the two plugged in. LED light source circuit board 9, constant current driving power supply (driver) 5, support 8 is a bar-shaped groove body with a boss, and the two walls of the upper part of the bracket seat cavity are provided with LED light source circuit board slots, which are plugged with LED light source circuit board 7 Then, of course, the same purpose can also be achieved by providing parallel bumps on the cavity walls on both sides. The LED light source circuit board is composed of light-emitting diodes and printed circuits on the back of the PCB board. The distance between the neck of the light-em...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com