Differential confocal-low coherent interference combination refractivity and thickness measurement method and apparatus

A low-coherence interference and differential confocal technology, which is applied in the direction of measuring devices, using optical devices, testing optical properties, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

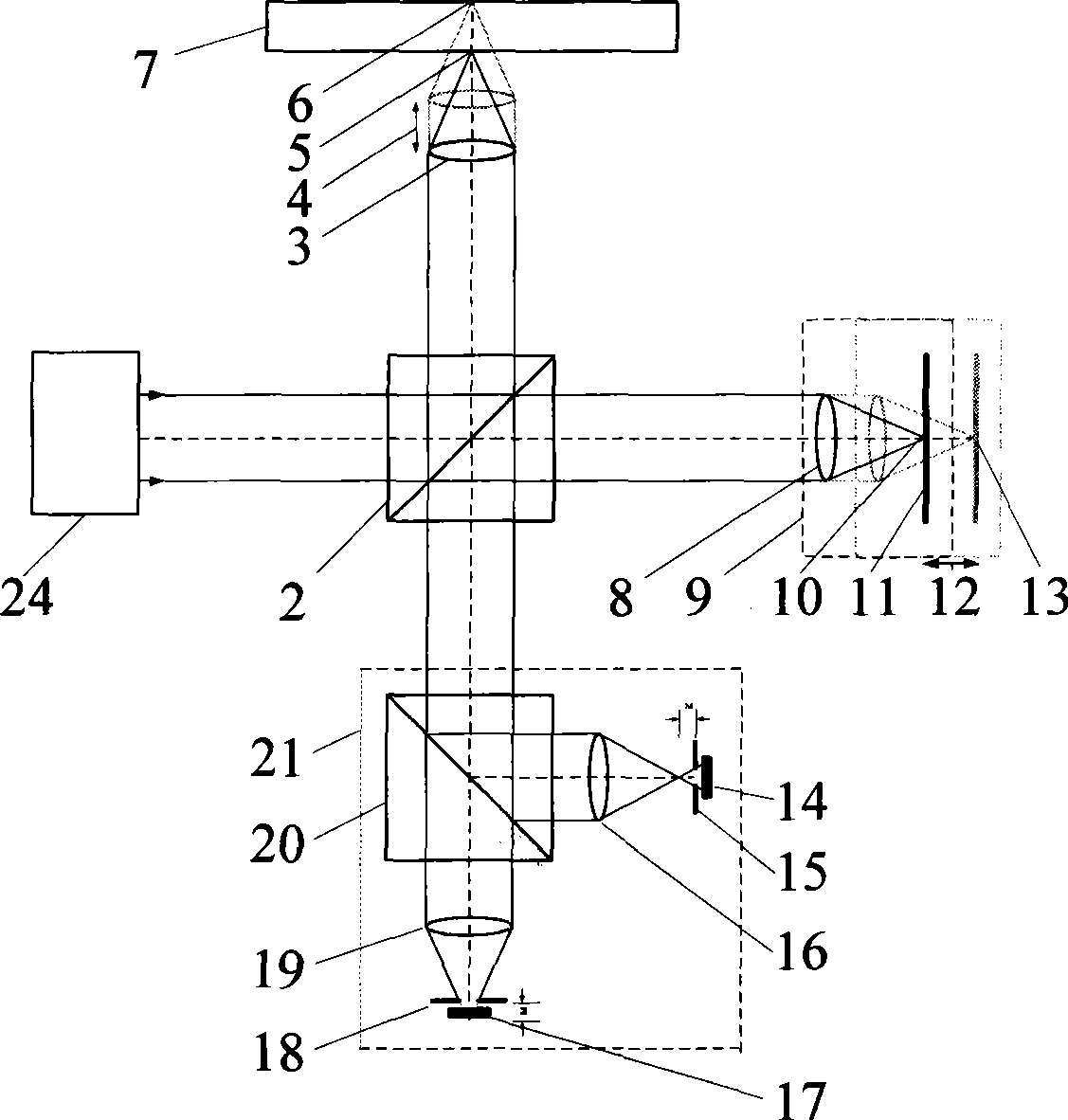

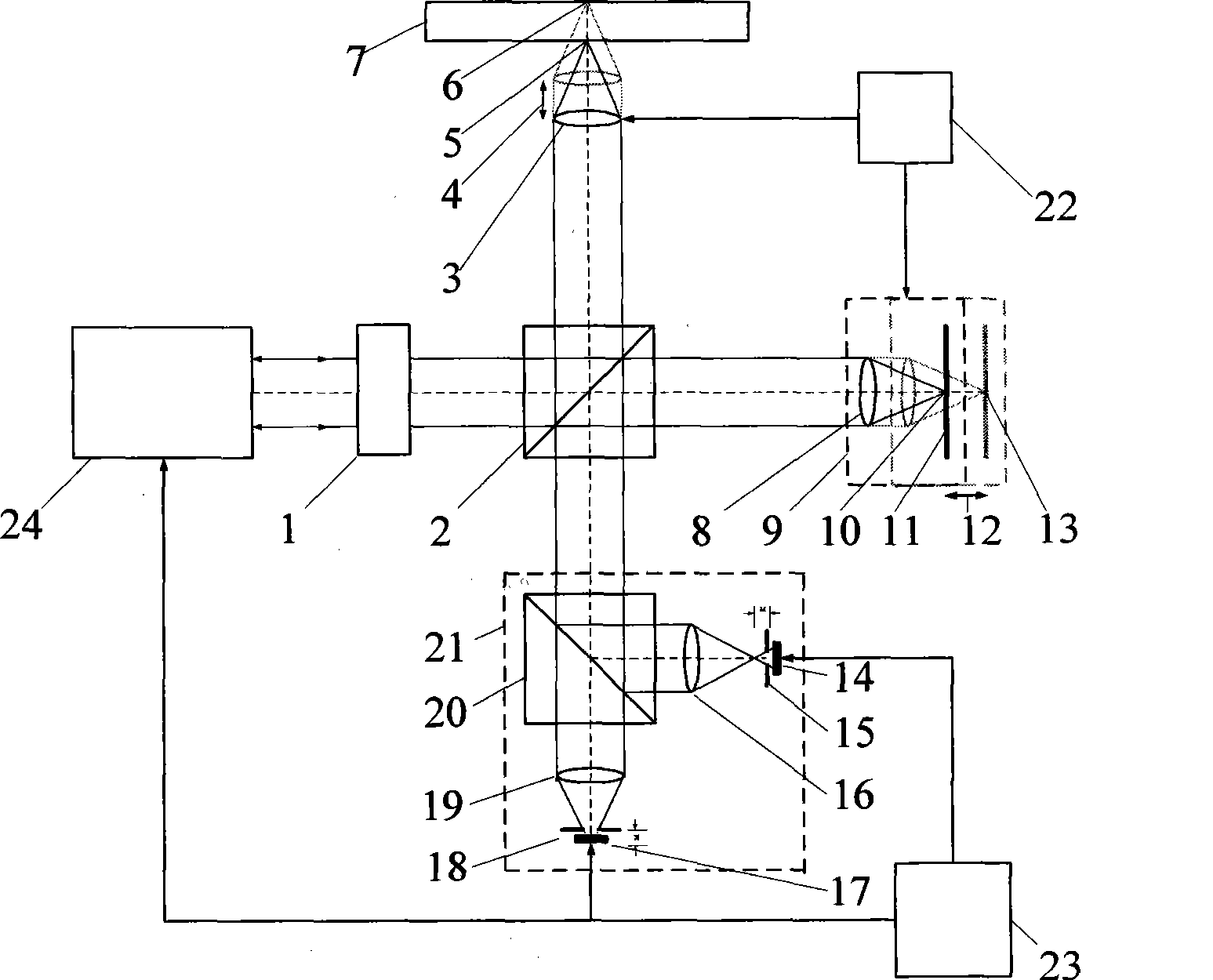

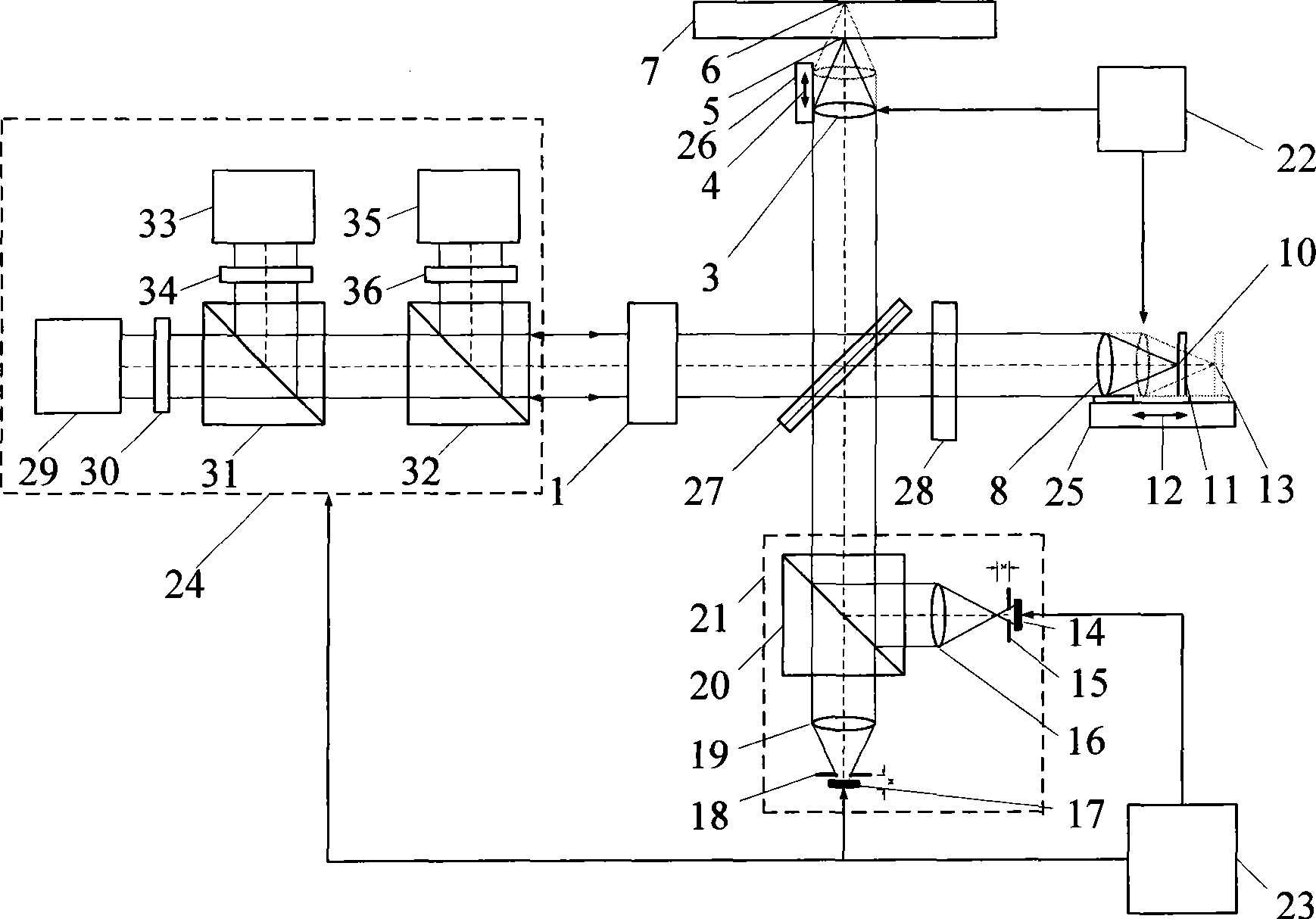

[0046] The basic idea of the present invention is to use the principle of differential confocal to achieve precise focusing to obtain the relationship between the phase refractive index and the geometric thickness of the sample, and to obtain the relationship between the group refractive index and the geometric thickness of the sample by low-coherence interferometry, and to use different wavelengths Multiple sets of measurement data can be obtained from the laser light source measurement, and sufficient information for measuring the refractive index and geometric thickness of the sample can be obtained.

[0047] The present invention will be described in detail below by taking the measurement of the geometric thickness and refractive index of the sample B270 as an example in conjunction with the accompanying drawings.

[0048] In the measurement, the measured crystal is B270, and the light sources used are lasers with wavelengths of 814nm and 1050nm respectively.

[0049] Su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com