Method and apparatus for removing impurities in rejects from sequential filters using separate treatment units

A processing unit and filter technology, applied in the directions of loose filter material filters, gravity filters, chemical instruments and methods, etc., can solve different treatment methods, the first waste liquid and the second waste liquid have different chemical compositions , different impurity levels, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The details of the present invention will be explained below with reference to the accompanying drawings.

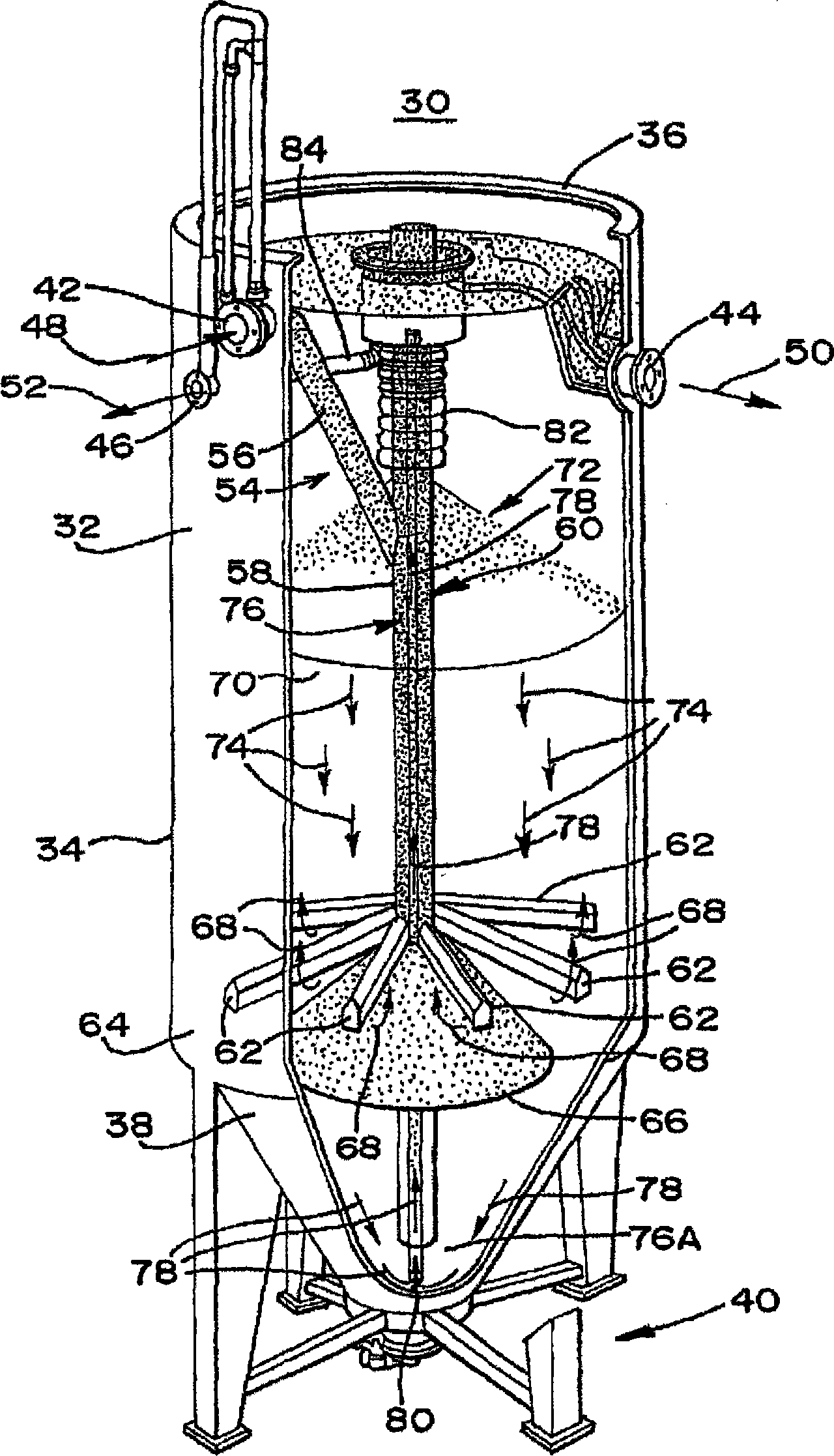

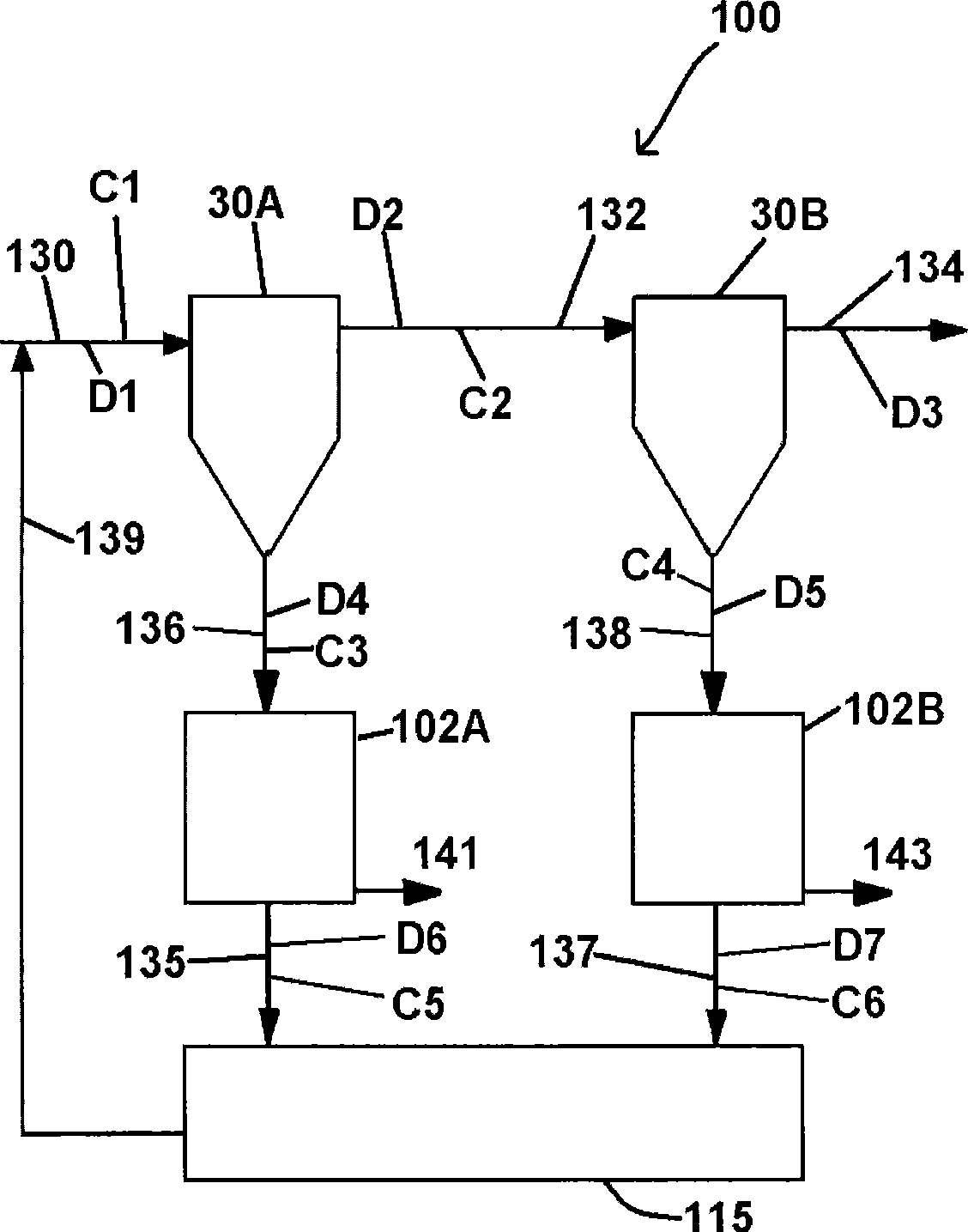

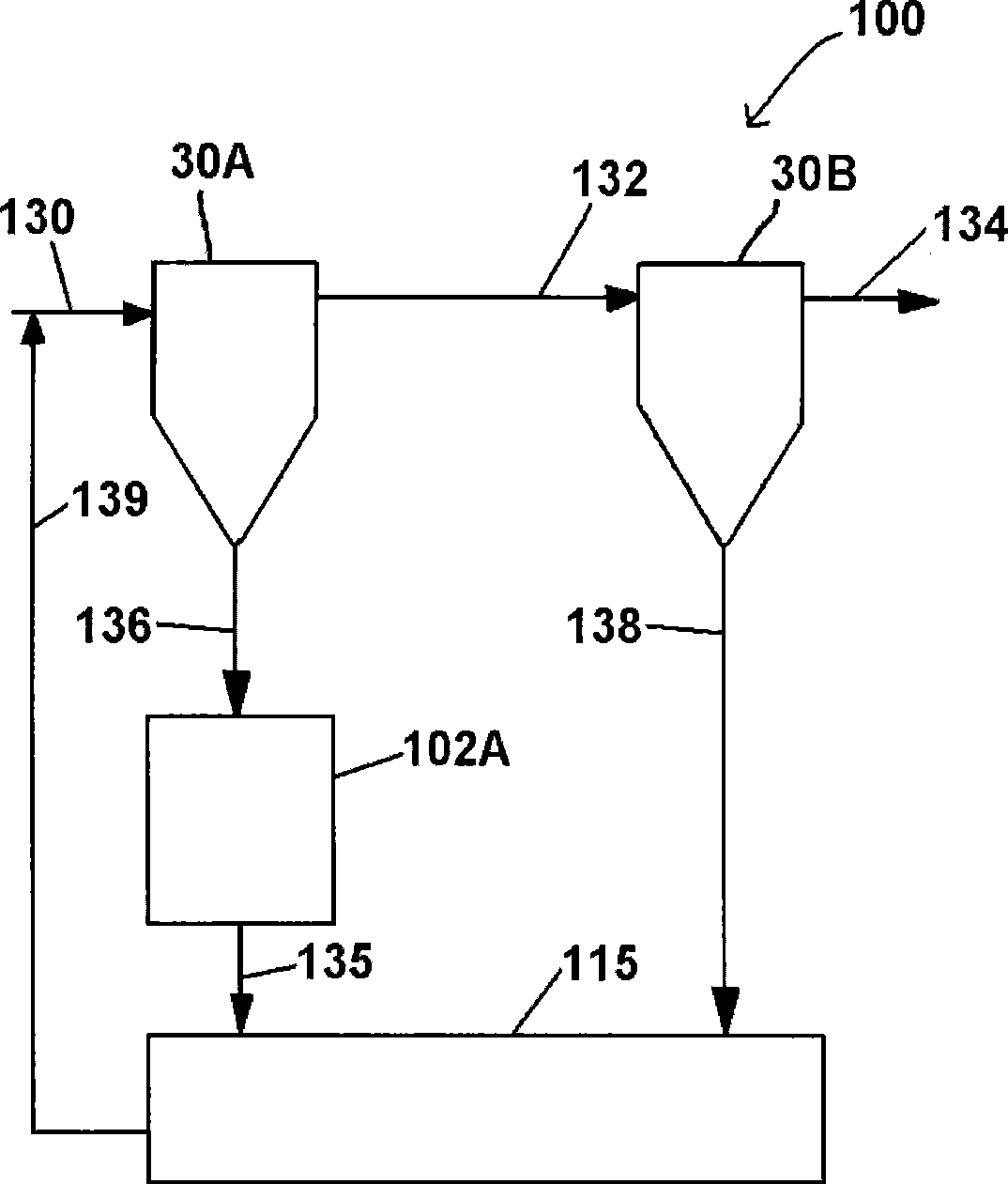

[0036] figure 1 A sand filter 30 that can be operated continuously in an existing wastewater treatment process is shown. Such sand filters 30 are of a conventional type and are disclosed in US Patent Nos. 4,126,546; 4,197,201; 4,246,102; and 6,426,005, which are incorporated herein by reference. As discussed next, if figure 2 As shown, two identical sand filters 30 each plus an independent processing unit can be connected together for serial operation.

[0037] The sand filter 30 includes a housing 32 having a generally cylindrical outer wall 34 extending from a top end 36 to a funnel-shaped end 38 . Such as figure 1 As shown, the outer wall 34 of the box body 32 extends downwards and surrounds the funnel-shaped end 38 to provide a vertical device 40, the box body 32 is supported by the vertical device 40, so that the box body 32 is kept vertical to the horiz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com