Automatic warehouse

A technology of automatic warehouse and warehouse, applied in the field of automatic warehouse, to achieve the effect of high degree of freedom and versatility, effective use of factory space, and high storage efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0061] Next, an example (embodiment 1) of the present invention will be described.

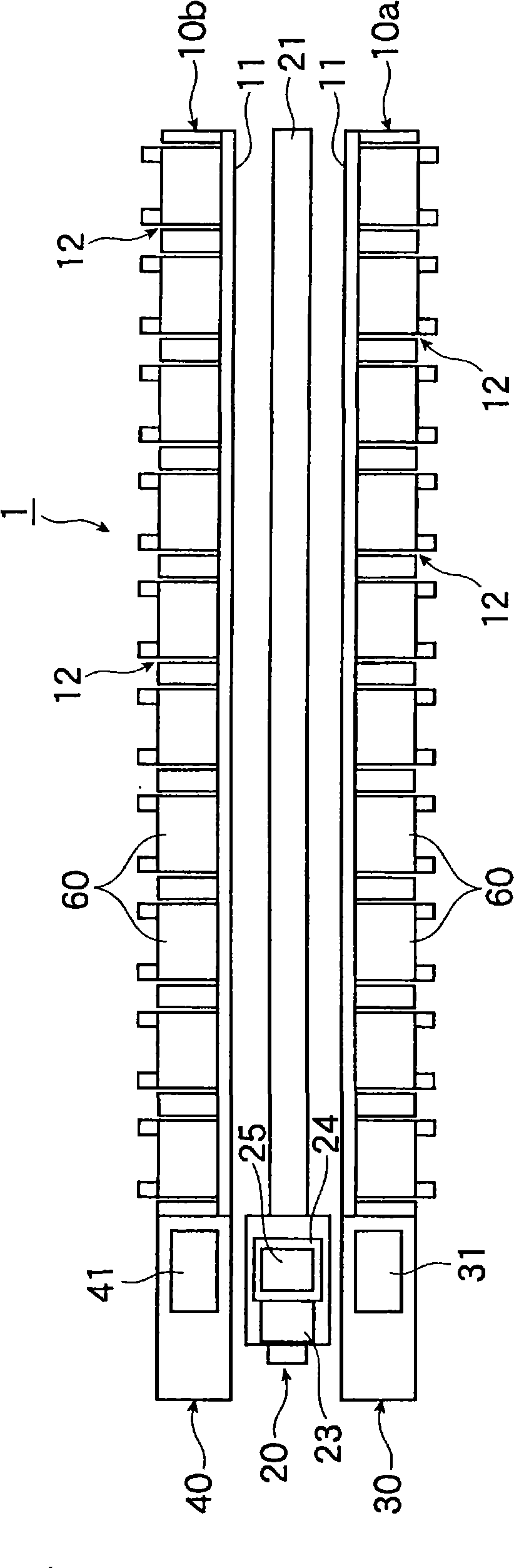

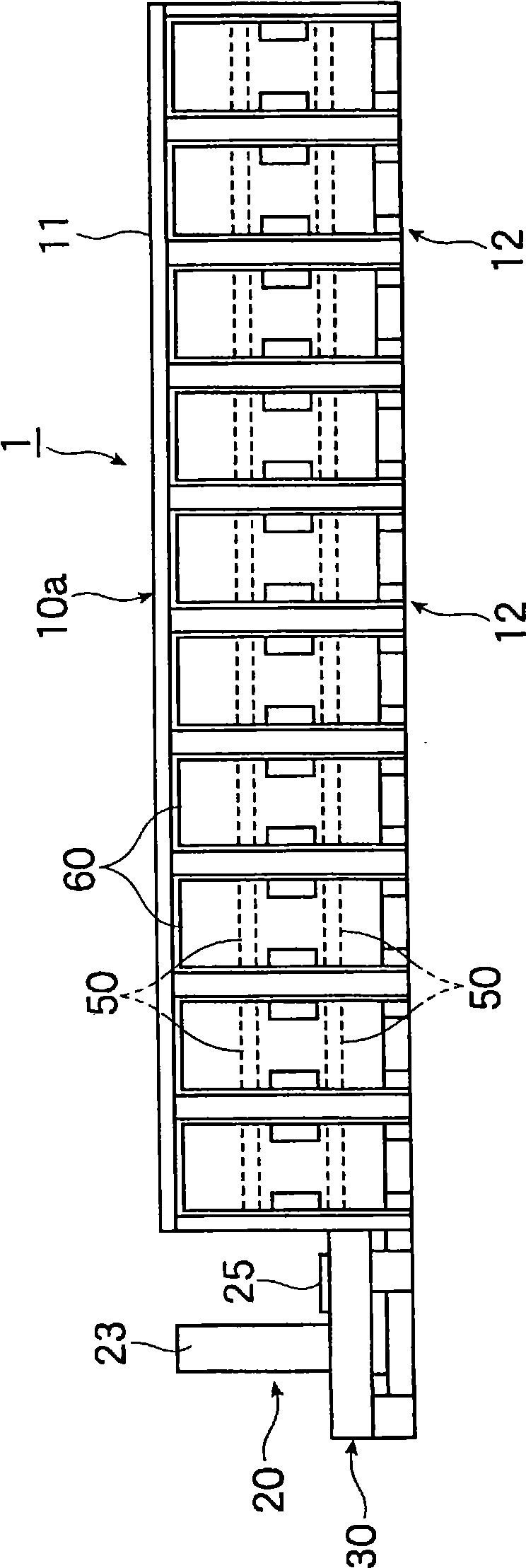

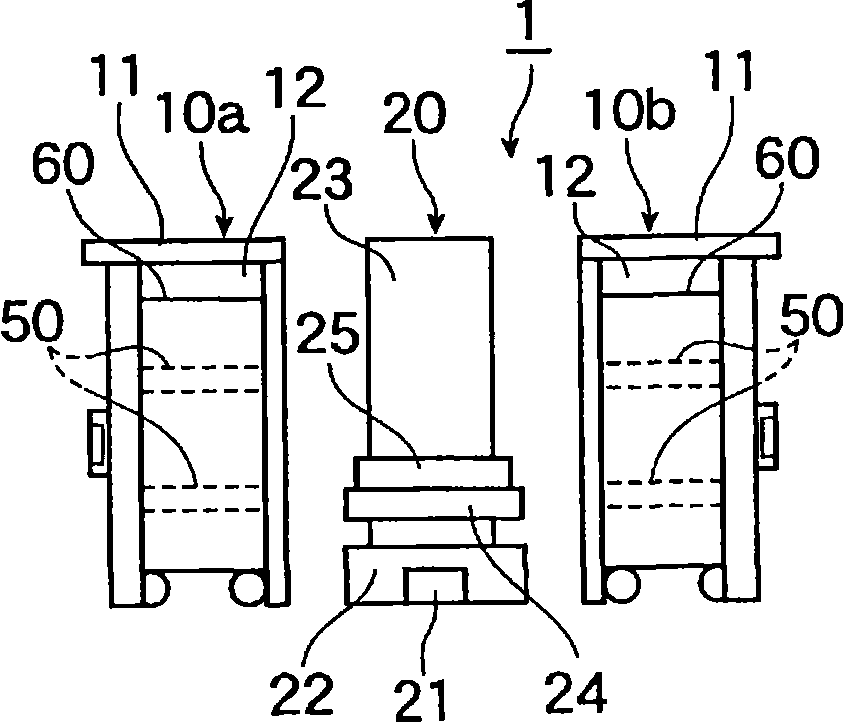

[0062] Figure 1A ~ Figure 1C It is a figure showing the automatic warehouse of this Example 1, Figure 1A is its floor plan, Figure 1B is its front view, Figure 1C is its side view. also, Figure 2A ~ Figure 2C is a diagram showing the trolleys constituting the automatic warehouse, Figure 2A is its floor plan, Figure 2B is its rear view, Figure 2C is its side view.

[0063] The automatic warehouse of the present embodiment 1 is used in manufacturing and assembling factories of various products, especially in factories adopting the cell production method.

[0064] The overall structure of the automatic warehouse 1 of the present embodiment 1 is roughly as follows Figure 1A ~ Figure 1C As shown, a conveying device 20 is arranged between a pair of warehouse units 10a, 10b that are long and facing each other in the horizontal direction, and a plurality of shelves are respectively p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com