Bimetal charging barrel and manufacturing method thereof

A bimetal and barrel technology is applied in the field of bimetal barrels and their production, which can solve the problems of material waste and complicated barrel process, and achieve the effect of simple process and material saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

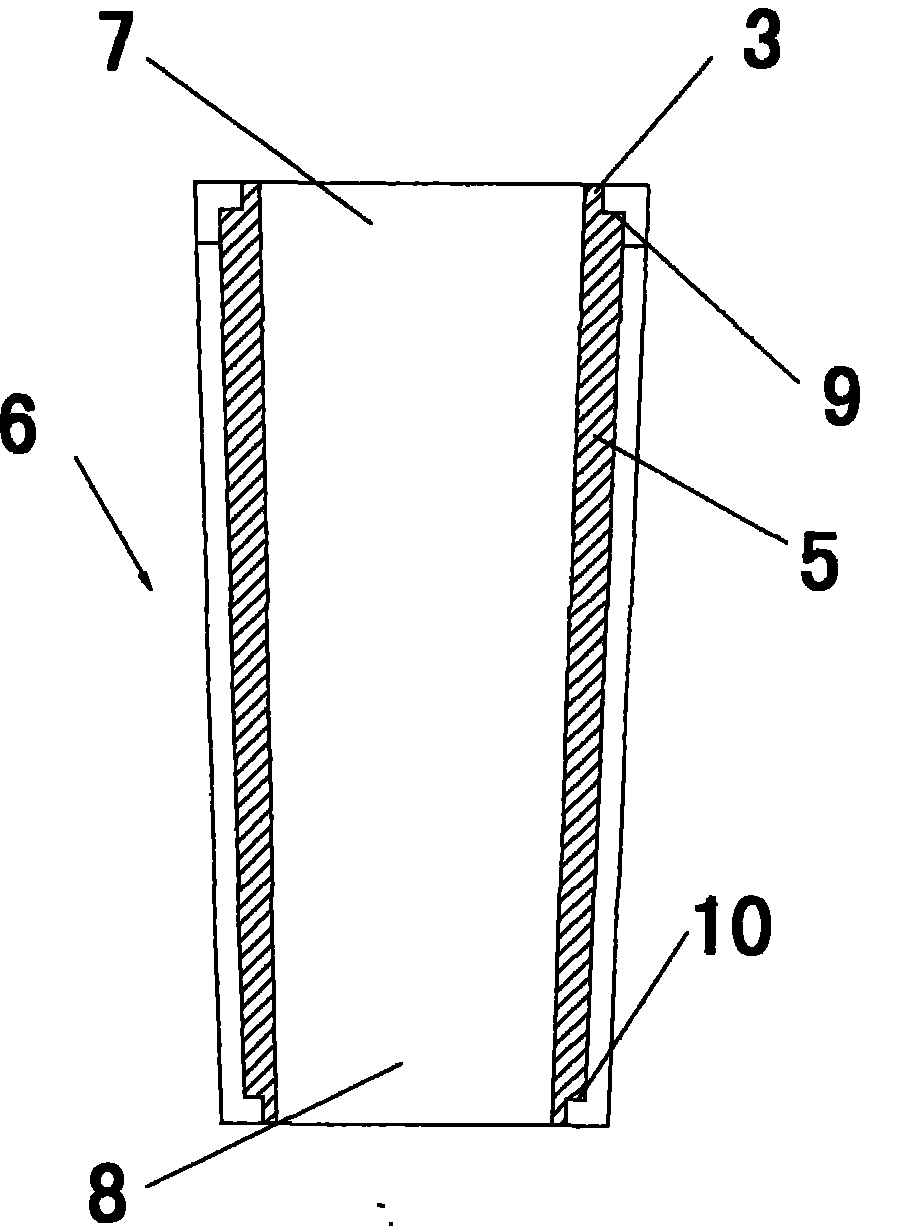

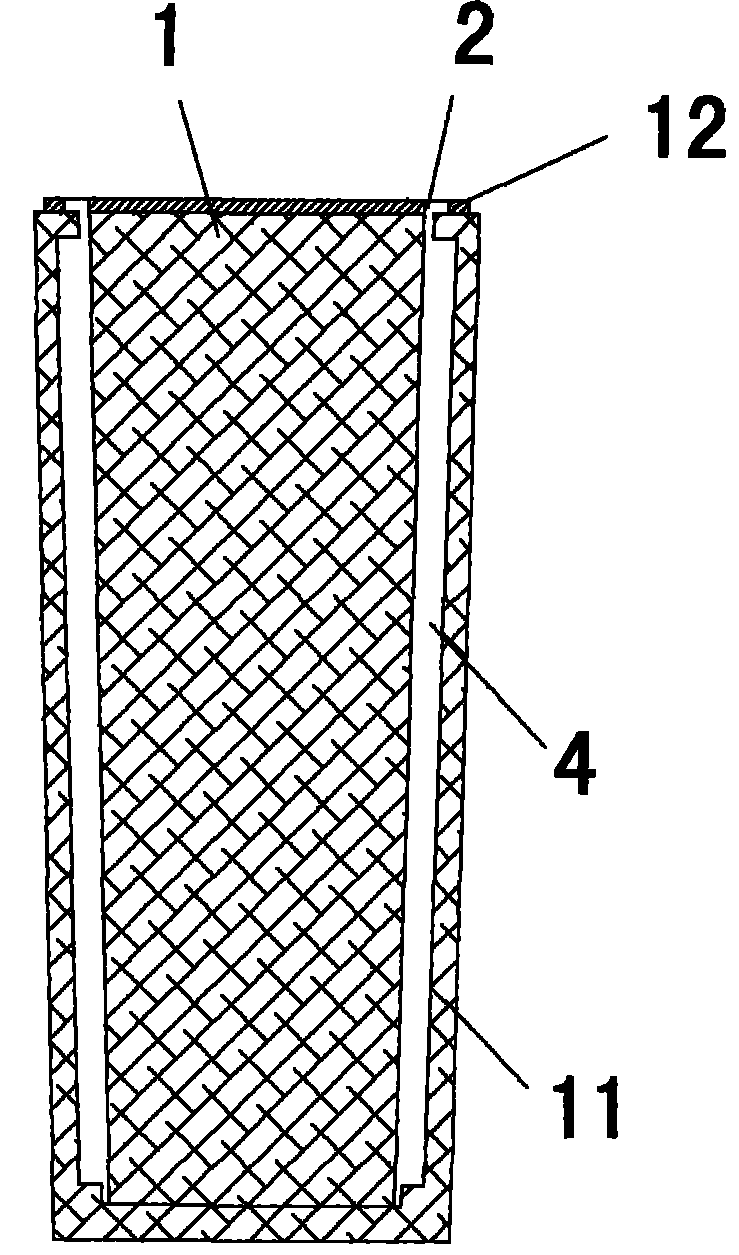

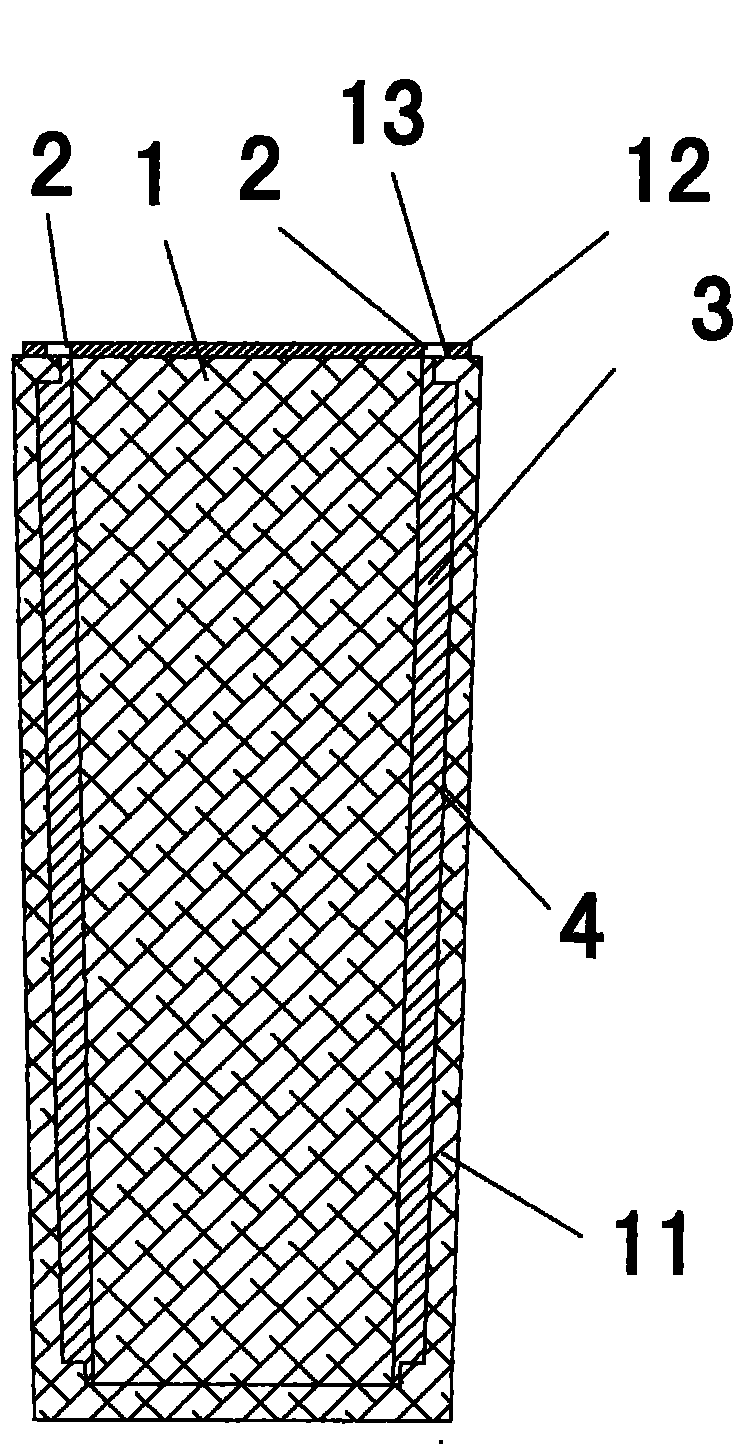

[0037] The bimetal barrel of this specific embodiment, such as figure 1 As shown, the alloy layer 3 and the barrel 6 are included. The structure of barrel 6 is as Figure 5 As shown, it includes an upper barrel 7 and a lower barrel 8 . The upper barrel 7 has an upper groove 9, and the lower barrel 8 has a lower groove 10. The upper barrel 7 and the lower barrel 8 are matched together to form a barrel groove that is only provided in the middle. And the barrel groove does not penetrate to the barrel 6 at both ends of the barrel. The structure of the alloy layer 3 is as Figure 4 As shown, the alloy layer 3 is only provided with a protrusion 5 in the middle, and the protrusion 5 does not extend to both ends of the alloy layer 3 . In the assembly process, the alloy layer 3 is first put into the lower barrel 8, and then the upper barrel 7 is fixed on the lower barrel 8 by screws or glued. After the alloy layer 3 is matched and assembled with the barrel 6 , the protrusion 5 is ...

Embodiment 2

[0047] The bimetal barrel of this embodiment, the steps of its manufacturing method are the same as the steps in Embodiment 1, the difference is that the structure of the mold core 1 of the mold used in the manufacture is different, such as Figure 10 As shown, it is a perspective view of the mold core 1 of this specific embodiment. The cross section of the mold core 1 in Example 1 is a double-hole structure in the shape of an "8", so the specific embodiment of this specific embodiment is made by the mold in this specific embodiment. The difference between the bimetallic barrel and the bimetallic barrel in Example 1 is that the inner wall of the alloy layer 3 has a double-hole structure in the shape of an "8", and the three-dimensional view of the alloy layer in this specific embodiment is as follows Figure 11 shown.

Embodiment 3

[0049]The steps of the manufacturing method of the bimetallic barrel of this specific embodiment are the same as those in the specific embodiment 1, the difference is that, as Figure 12 As shown, the protrusions 5 of the alloy layer 3 are arranged in four at equal intervals.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com