Automatic pipe workpiece unloading device

An automatic unloading device and pipe technology, which is applied to conveyor control devices, transportation and packaging, furnace types, etc. The effect of safety and high discharge efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

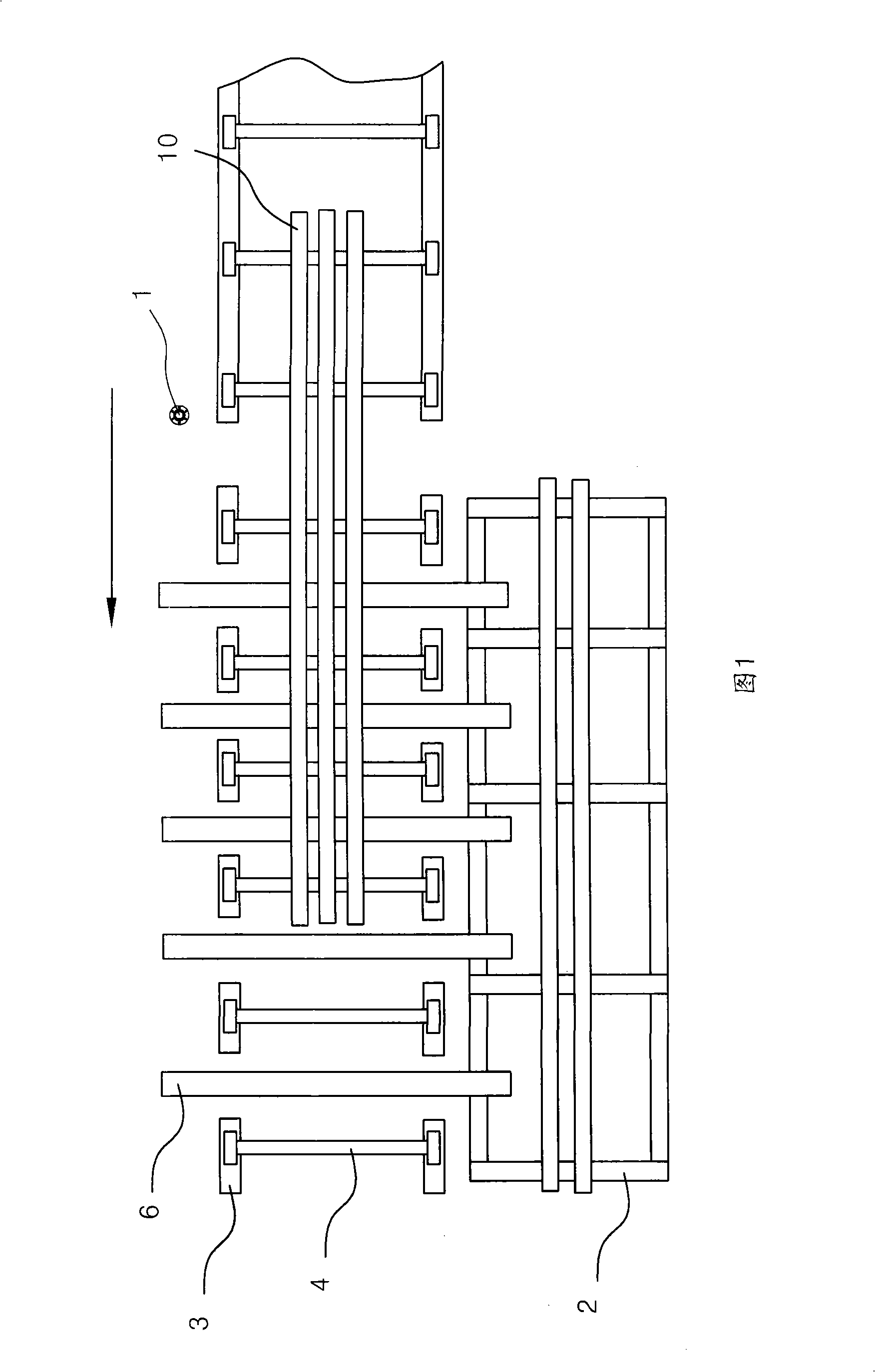

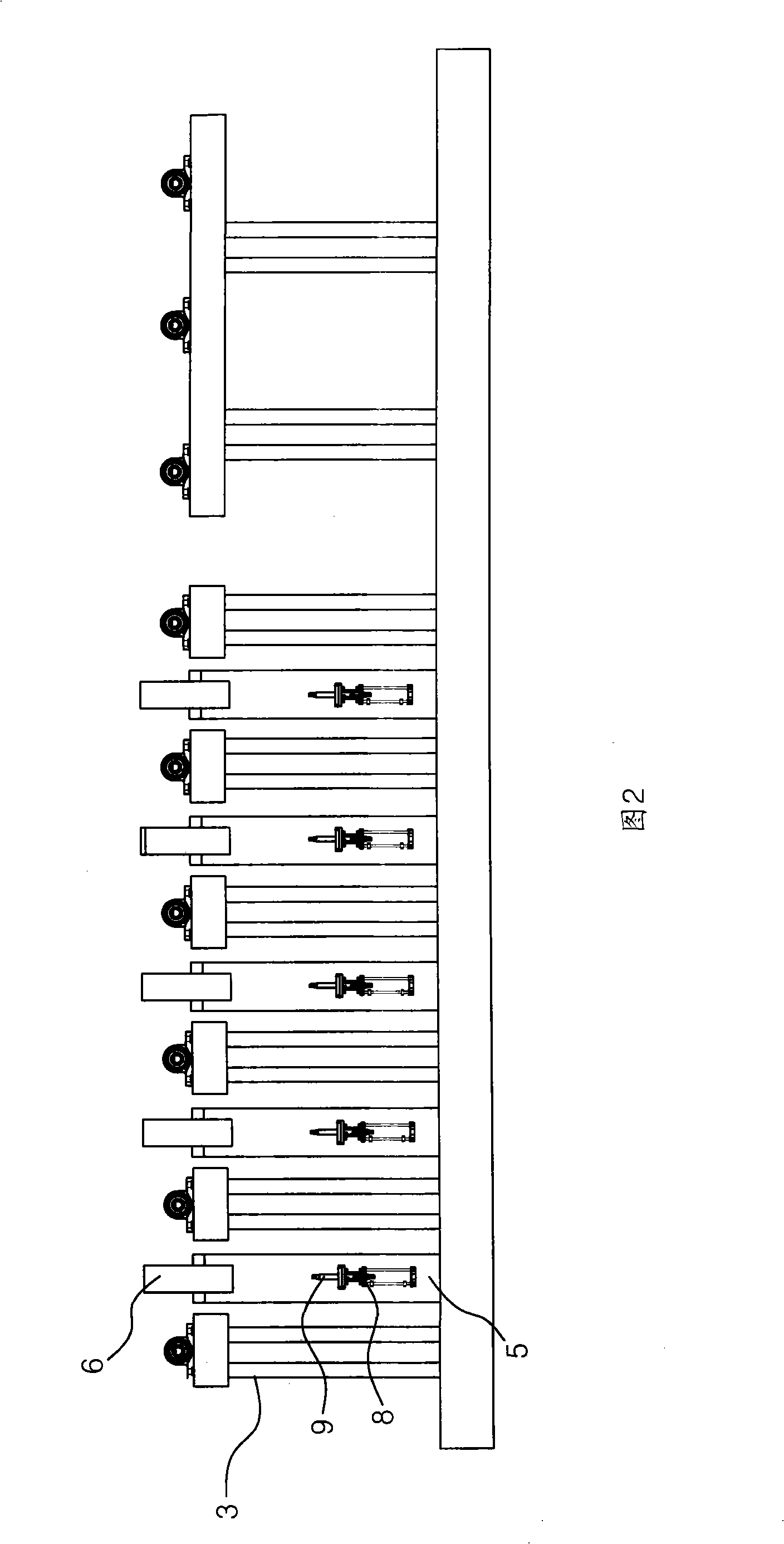

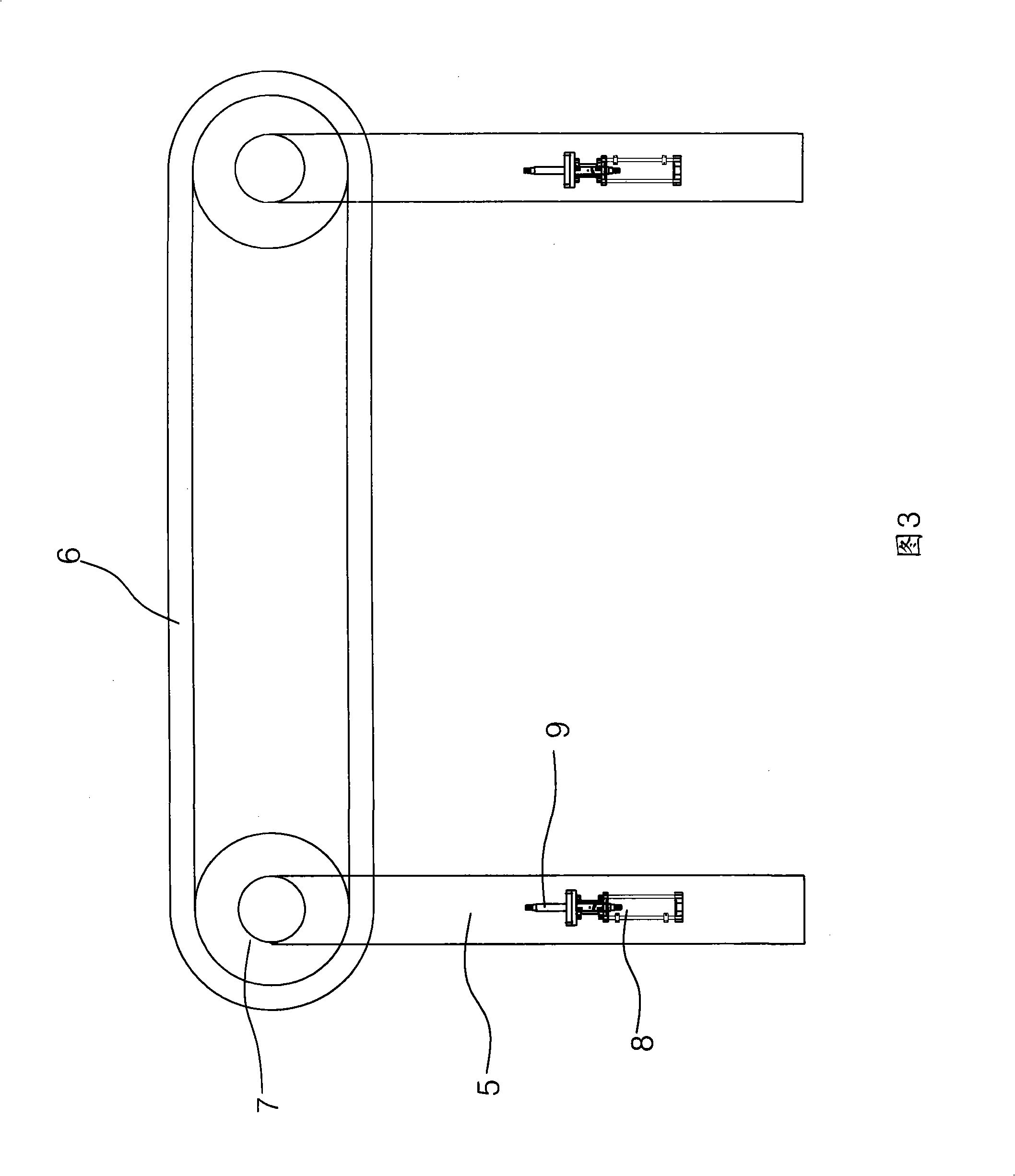

[0011] See attached figure 1 And attached figure 2 , an automatic unloading device for copper pipes, which includes a horizontal assembly line, a vertical assembly line, a photoelectric sensor 1, and a material rack 2, and the horizontal assembly line includes a first frame 3, a plurality of transmission rollers 4, and a plurality of transmission rollers 4 are arranged in parallel On the first rack 3. The end of the horizontal assembly line constitutes the unloading area, and the vertical assembly line is set in the unloading area. image 3 As shown, the vertical assembly line includes a second frame 5, a plurality of conveyor belts 6, multiple sets of pulleys 7, and a lifting mechanism. The lifting mechanism includes a cylinder 8 and a cylinder rod 9, and the outer end of the cylinder rod 9 is connected to the vertical assembly line. . Conveyor belt 6 is arranged on unloading area, and each group pulley 7 all is made up of two pulleys 7 that are distributed on the left an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com