High strenght steel sheet having superior ductility and method for manufacturing the same

一种高强度钢板、钢板的技术,应用在高强度钢板领域,能够解决低屈服应力、磷化处理性能合金化热浸镀锌性能劣化、不能说实现延展性等问题,达到优良耐腐蚀性能、优异延展性、优异磷化处理性能的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

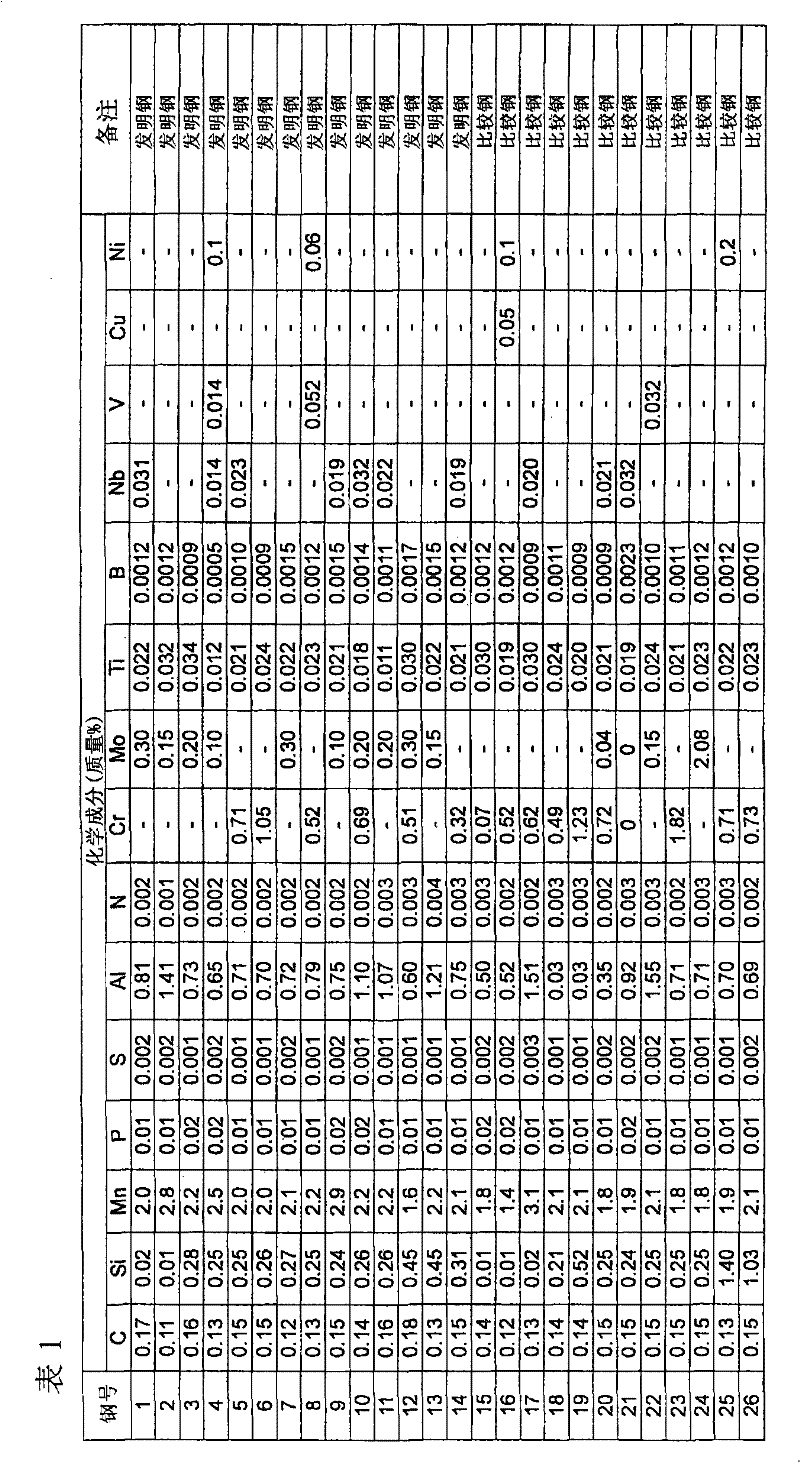

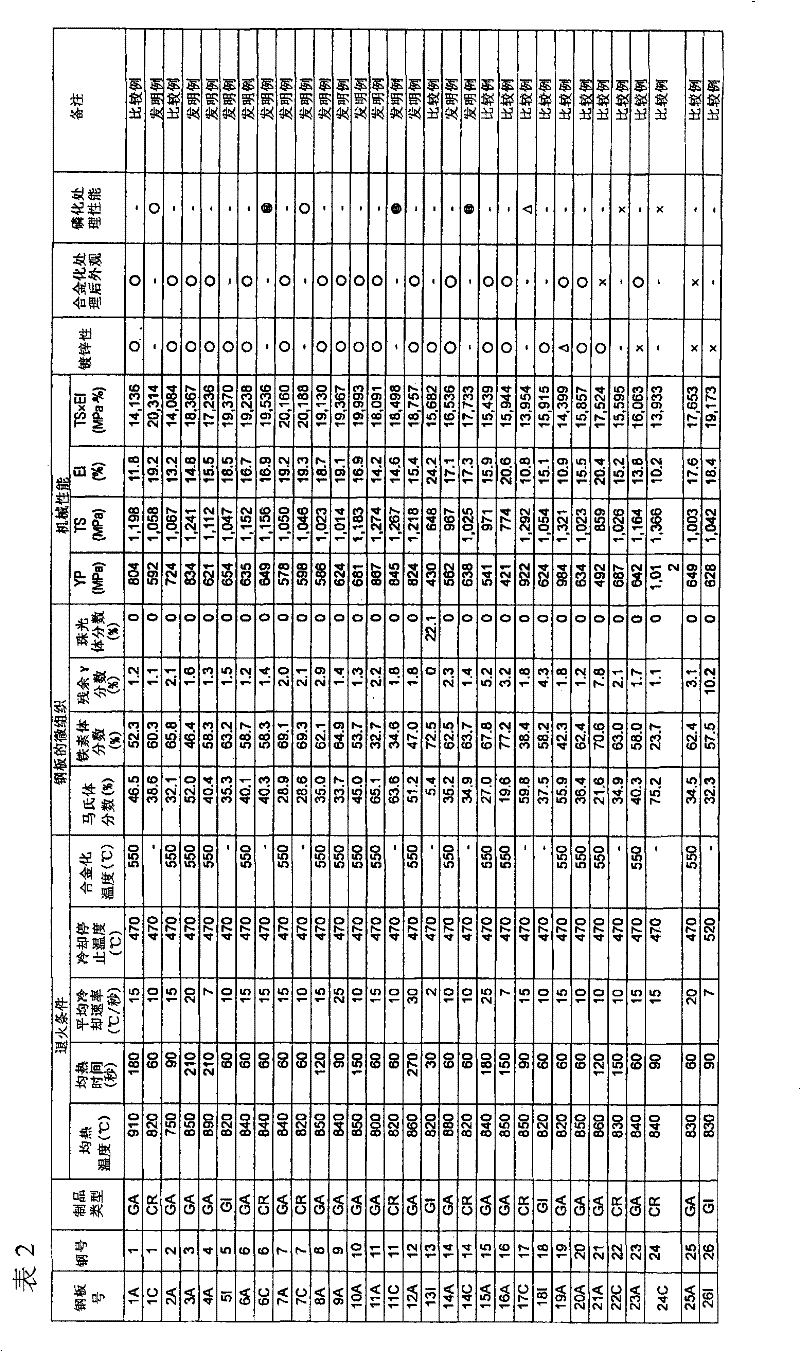

[0074] After each of Steel Nos. 1 to 26 having the composition shown in Table 1 was melted in a vacuum melting furnace to form a small ingot, the ingot was then heated to 1,250°C and kept for 1 hour, followed by hot rolling to obtain Hot-rolled steel plate with a thickness of 3.5mm. In this process, the finishing temperature of hot rolling was set at 890°C, and cooling was performed at an average cooling rate of 20°C / s after rolling, followed by heat treatment at 600°C for 1 hour, which corresponds to 600 °C coiling temperature. Next, after the hot-rolled steel sheet was treated by pickling, and then cold-rolled to a thickness of 1.5 mm, the cold-rolled steel sheet was subjected to reducing gas (containing N) under the conditions shown in Table 2. 2 and 5 vol% H 2 ) to perform annealing so as to form a cold-rolled steel sheet (CR). In addition, after the above-mentioned annealing, part of the cold-rolled steel sheet is immersed in a hot-dip galvanizing bath at a temperature...

Embodiment 2

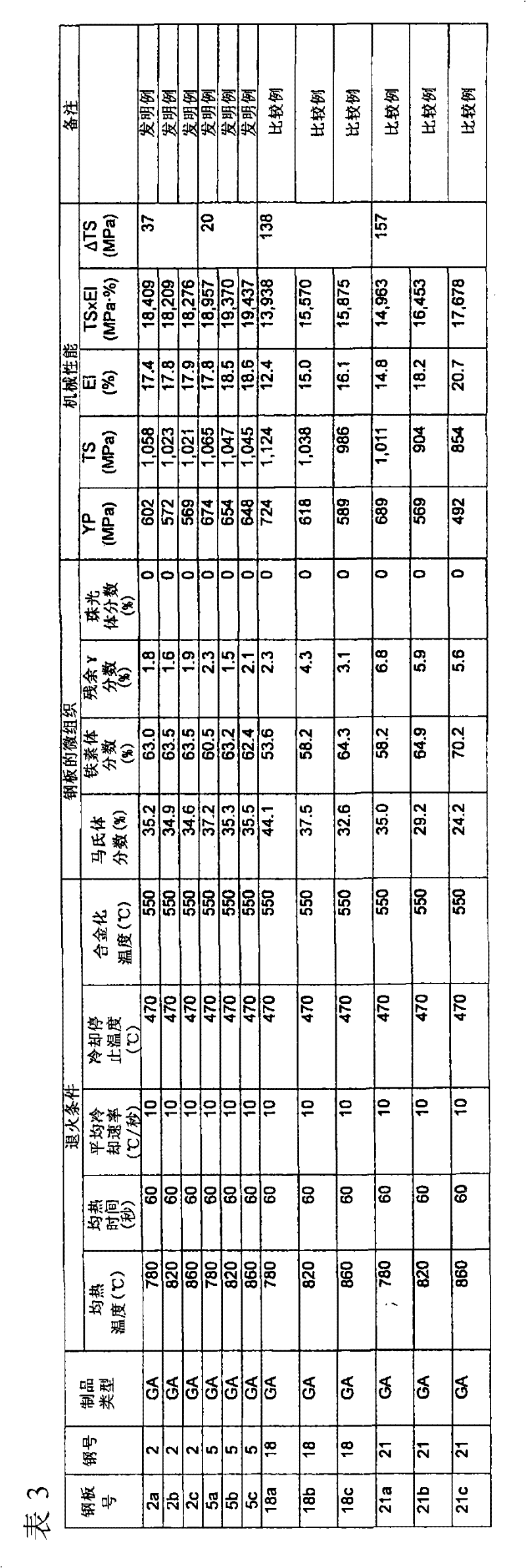

[0102] Alloyed galvanized steel sheets (GA) were each formed by forming cold-rolled steel sheets from each of the ingots No. 2, 5, 18, and 21 shown in Table 1 under the conditions shown in Example 1. Annealing was performed under fixed conditions, except that the soaking temperature was changed to 780, 820, and 860°C as shown in Table 3, and then hot-dip galvanizing was performed, followed by alloying treatment.

[0103] In a similar manner to Example 1, the microstructure and mechanical properties of the above alloyed hot-dip galvanized sheet were investigated, and the results are also shown in Table 3.

[0104]

[0105] It can be seen from Table 3 that in the steel sheets obtained from steel Nos. 18 and 21 that do not satisfy the composition of the present invention, the change in tensile strength ΔTS obtained when the soaking temperature is changed in the range of 780 to 860°C is significantly greater than that of 100 MPa; however, in the steel sheets obtained from Steel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com