Multi-scale test machine for measuring lubricating oil film by optical interference method

A lubricating oil film, multi-scale technology, applied in the direction of measuring devices, optical devices, instruments, etc., to achieve the effect of convenient operation, low manufacturing cost, and increased reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] A preferred embodiment of the present invention is described in detail as follows in conjunction with accompanying drawing:

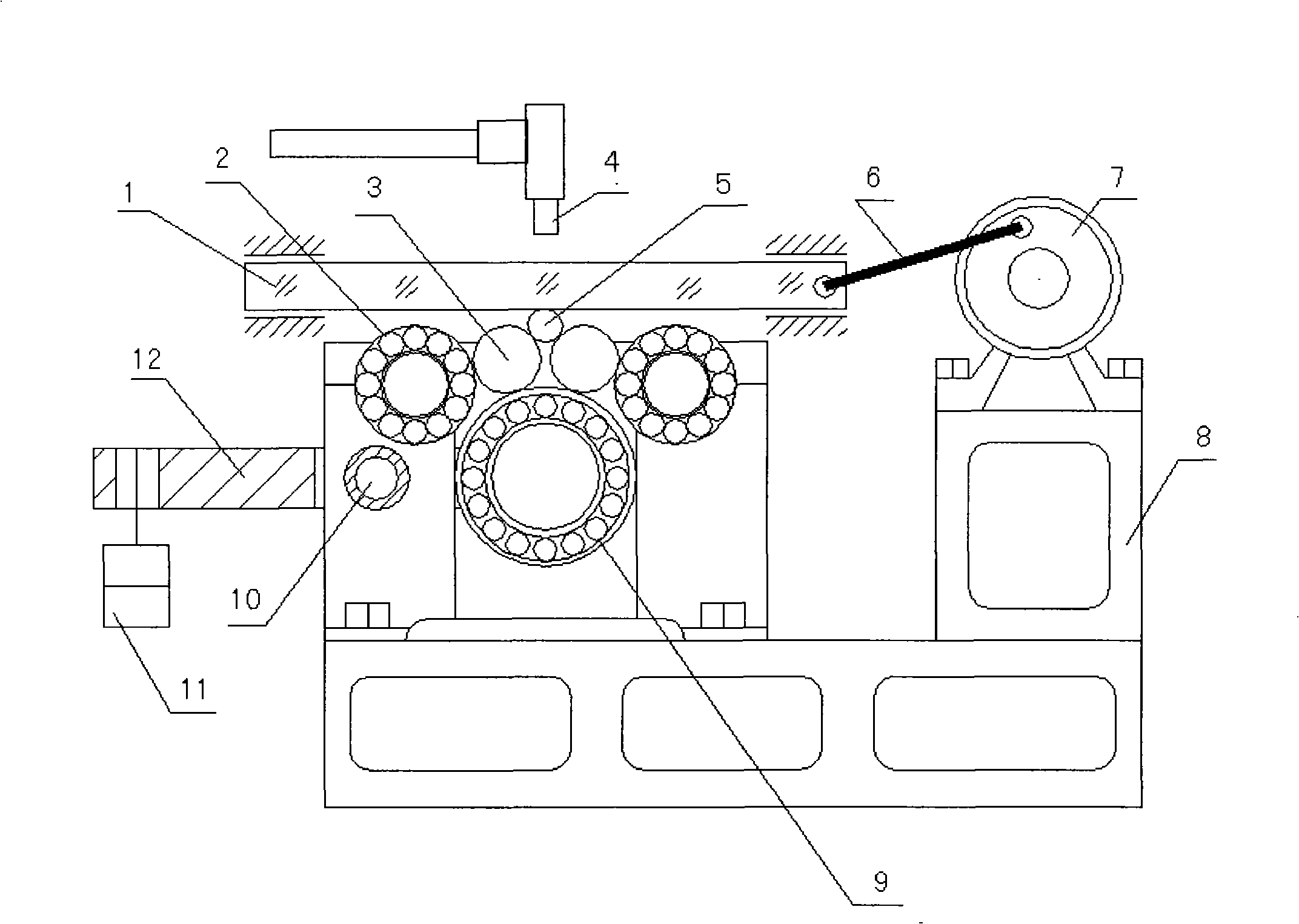

[0024] see figure 1 , the light interferometry multi-scale lubricating oil film measurement testing machine, including a base 8, a motor 7, a transmission device, a supporting device and a loading device, the motor 7 drives a horizontal sliding plane placed on the base through the transmission device The glass 1 makes a reciprocating horizontal movement; the supporting device is a floating supporting device, which supports the test piece 5 and is in rolling contact with the lower surface of the flat glass 1; the loading device is a lever-type loading mechanism, supporting the floating supporting device to make The test piece 5 applies pressure to the flat glass 1; a microscope for measuring the oil film is fixed above the flat glass, and its lens is aimed at the rolling contact line between the flat glass 1 and the test piece 5.

[0025] The abo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com