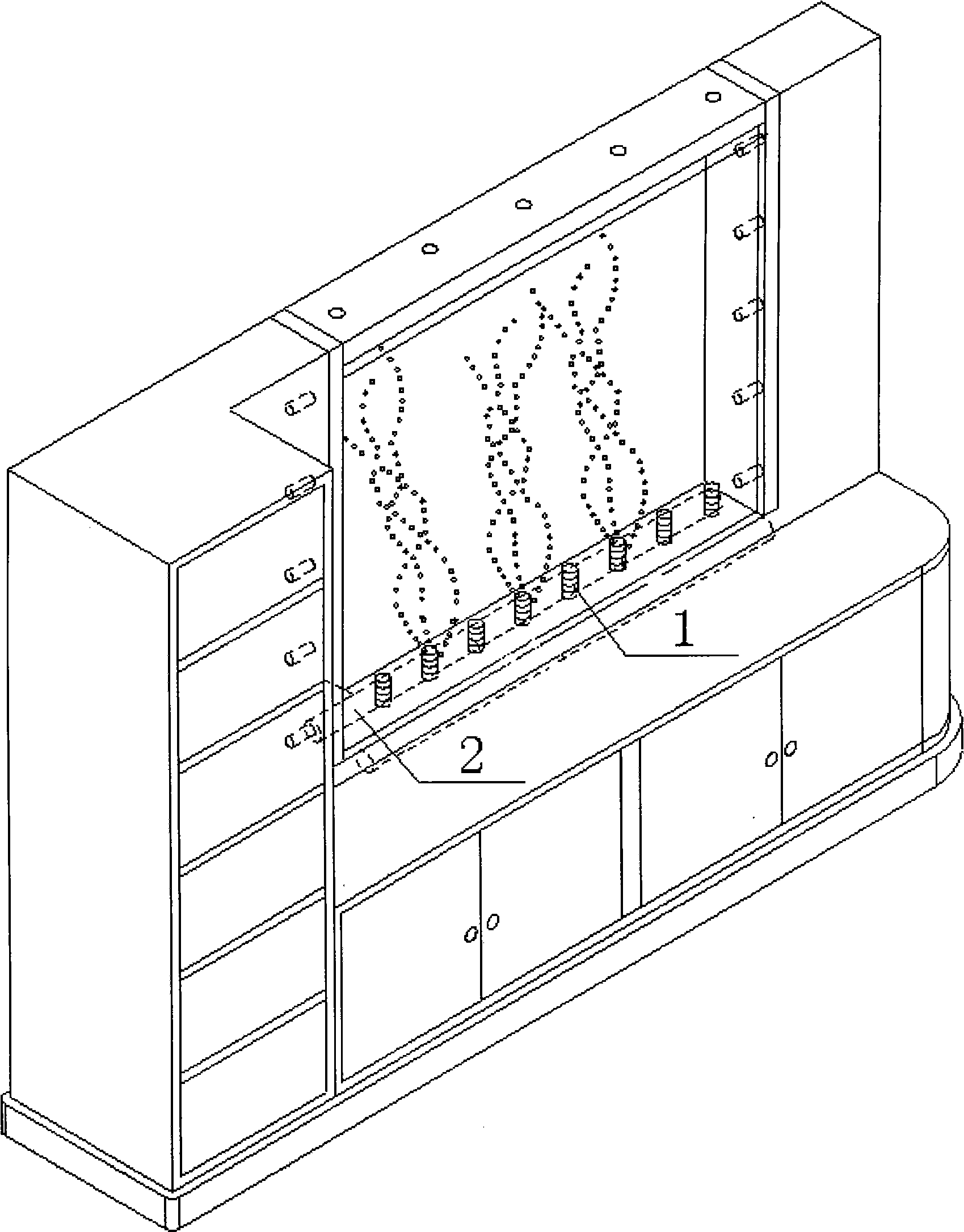

Jet head used in water-feature burble walls, as well as the press die and assembly method thereof

A technology of stamping die and jet head, applied in jetting device, jetting device, decorative arts and other directions, can solve the problems of frequent vibration, easy aging, short life and so on, and achieve the effect of simple and effective stamping die, fast processing and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

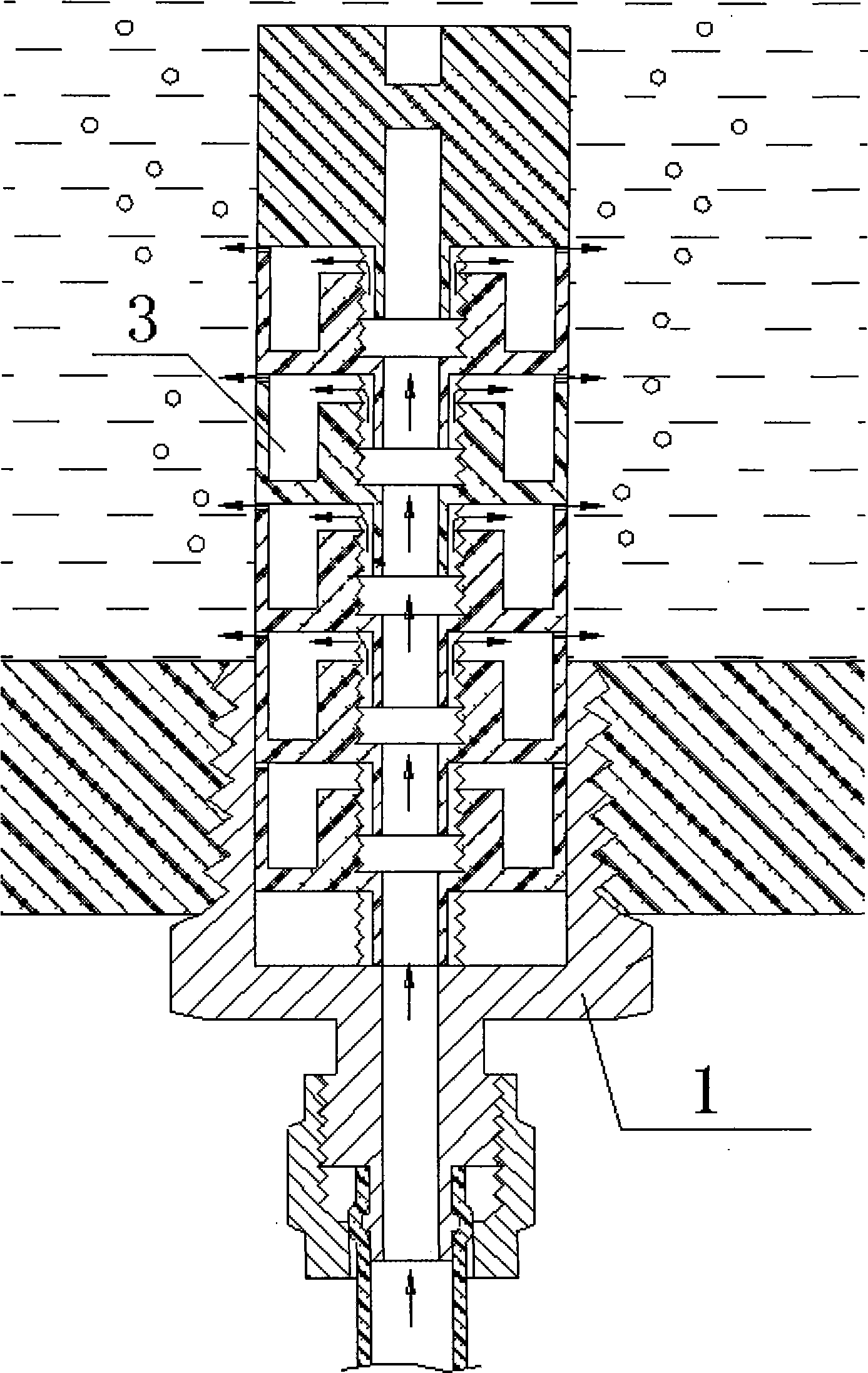

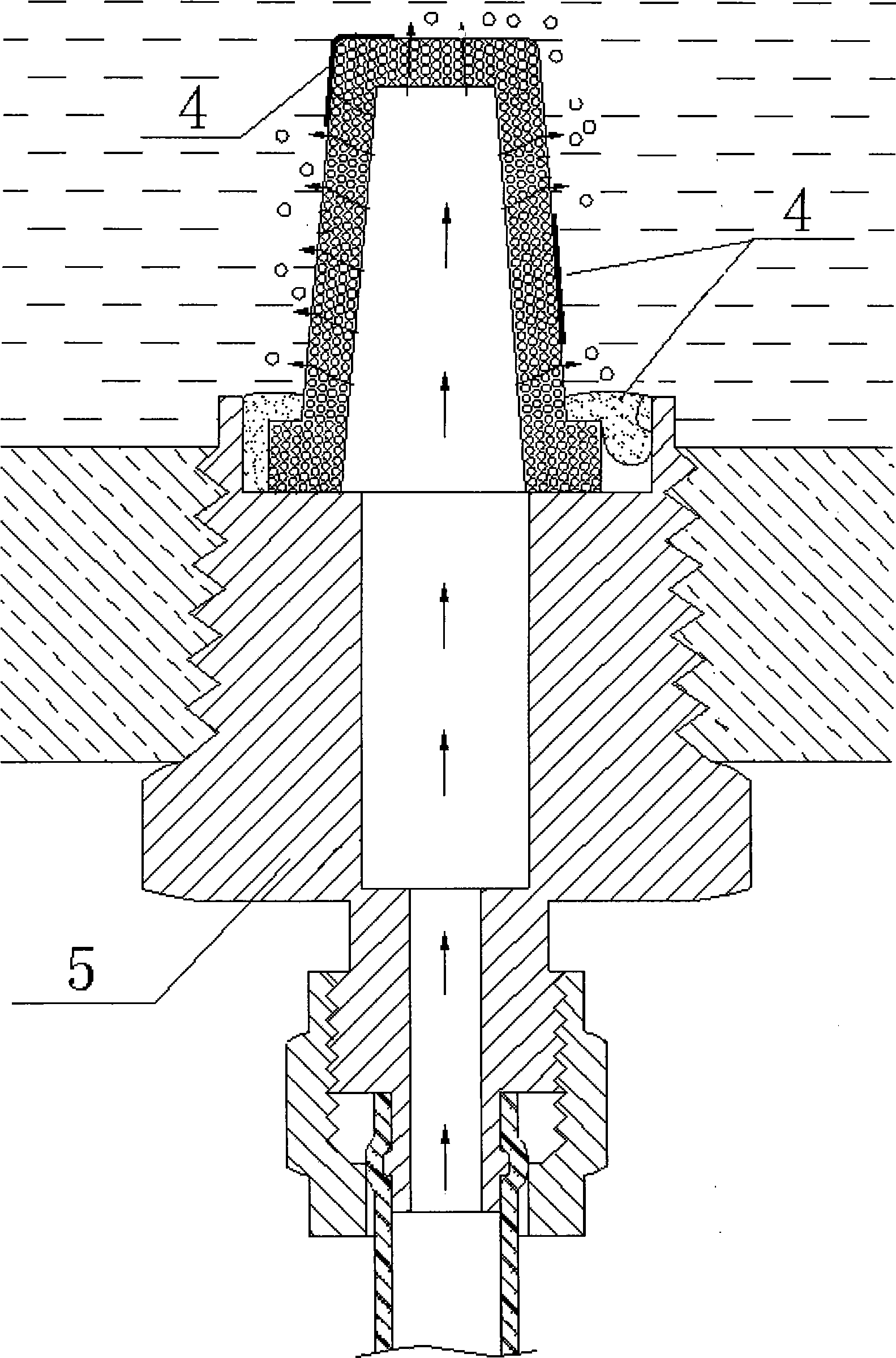

[0033] Implementation mode one: if Figure 4 As shown, the air nozzle for the water dance bubble wall of the present invention includes an air nozzle 3 and a mounting seat 5, wherein the air nozzle 3 is covered with micropores, and the lower end is provided with a protruding flange 6, which is formed by die-casting of metal particles through a multi-layer mesh plate. The upper part of the mounting seat 4 has a mounting hole 7, and the lower part is provided with an air inlet joint 12 communicating with the mounting hole 7. The lower end of the air nozzle 3 is installed in the mounting hole 7, and the lower end of the air nozzle 3 is matched with the bottom of the mounting hole 7. , the installation hole 7 is provided with four protrusions 8 evenly distributed around the installation hole 7, the above-mentioned protrusions 8 are bent inwards, pressed on the flange, so that the lower end of the air nozzle is closely connected with the bottom of the installation hole 7, and the jo...

Embodiment approach 2

[0034] Implementation mode two: if Figure 5 As shown: the protrusions 8 extend circularly along the installation hole 7 and are connected to each other in a tubular shape—hereinafter referred to as tubular protrusions.

[0035] Such as Figure 9 As shown: the air passage inside the mounting seat 4 includes a first ventilation area 13 and a second ventilation area 14, the air inlet joint 12 is connected to the first ventilation area 13, the first ventilation area 13 is connected to the second ventilation area 14, and the second ventilation area 14 is connected to the first ventilation area 13. The second ventilation area 14 is connected to the air nozzle 3 , wherein the diameter of the first ventilation area 13 is smaller than the diameter of the second ventilation area 14 . The diameter of the first ventilation area 13 is between 1-3 mm, and the diameter of the second ventilation area 14 is between 2-9 mm. The size of the micropores on the air nozzle 3 is between 20-70 μm. ...

Embodiment approach 3

[0036] Implementation mode three: if Figure 6 As shown, the stamping die of the present invention for assembling the air spray head of the water dance bubble wall includes upper and lower dies 9, 10, and is characterized in that: the front part of the upper die 9 is hollow, and its front end is in the shape of a truncated cone hole. The top surface and the peripheral surface of the taper hole 11 are rounded, and its size corresponds to the mounting seat 5 to be stamped, and the hollow part is enough to accommodate the air nozzle 3 .

[0037] Such as Figure 7 , 8 As shown, the method for assembling the spray head for the water dancing bubble wall described in the second embodiment using the stamping die described in the third embodiment includes the following steps:

[0038] ①. Place the mounting base 5 on the proper position of the lower mold 10, place the end of the air nozzle 3 with the flanging 6 in the mounting hole 7, and align the two;

[0039] ②. Operate the punchi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap