Sanitary towel package sealing machine and sealing method

A technology for packaging bags and sanitary napkins, which is applied in the field of packaging bag sealing machine manufacturing, can solve the problems that the automatic sealing of sanitary napkin packaging bags cannot be applied, and achieve the effects of novel structure design, stable working performance and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

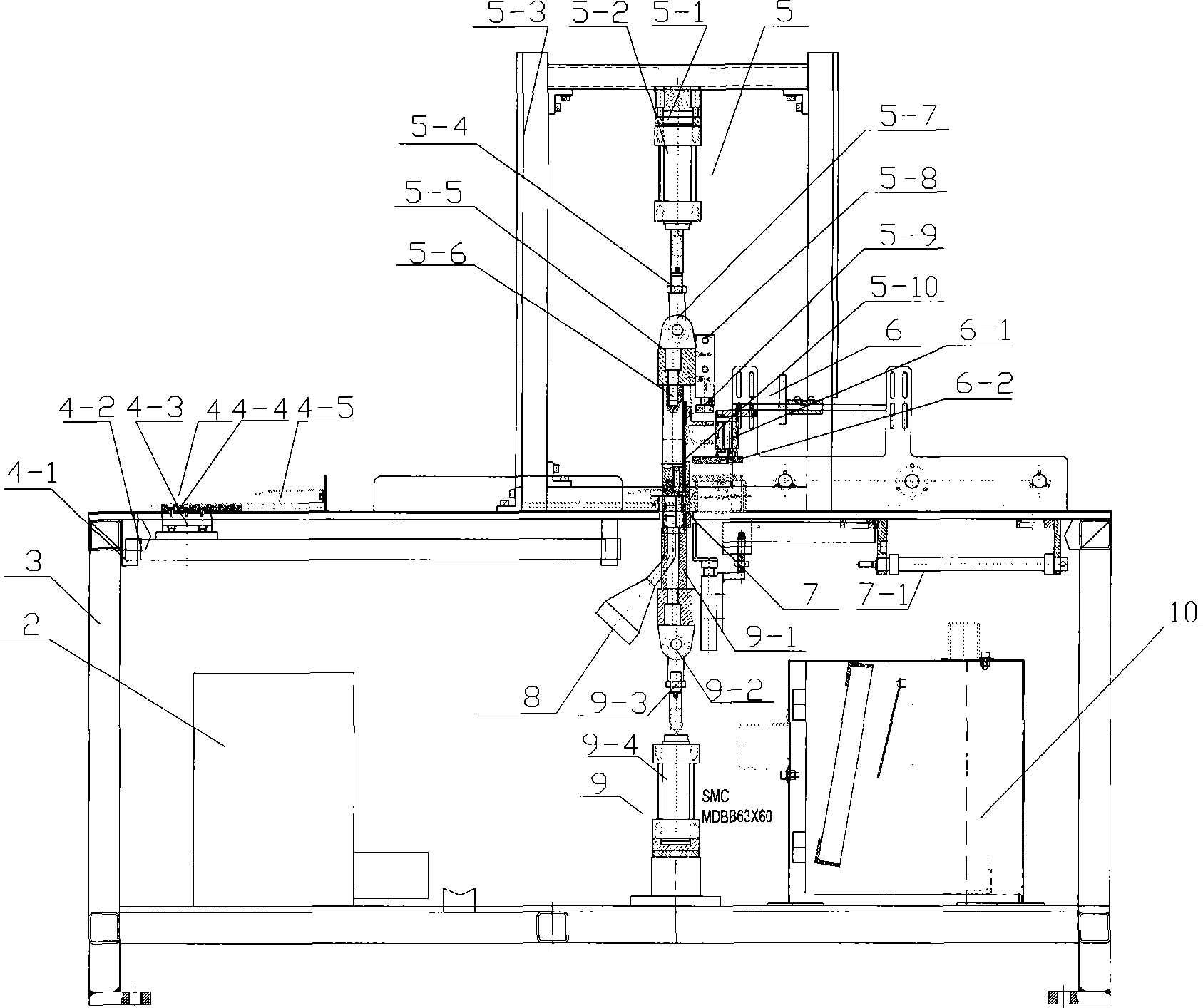

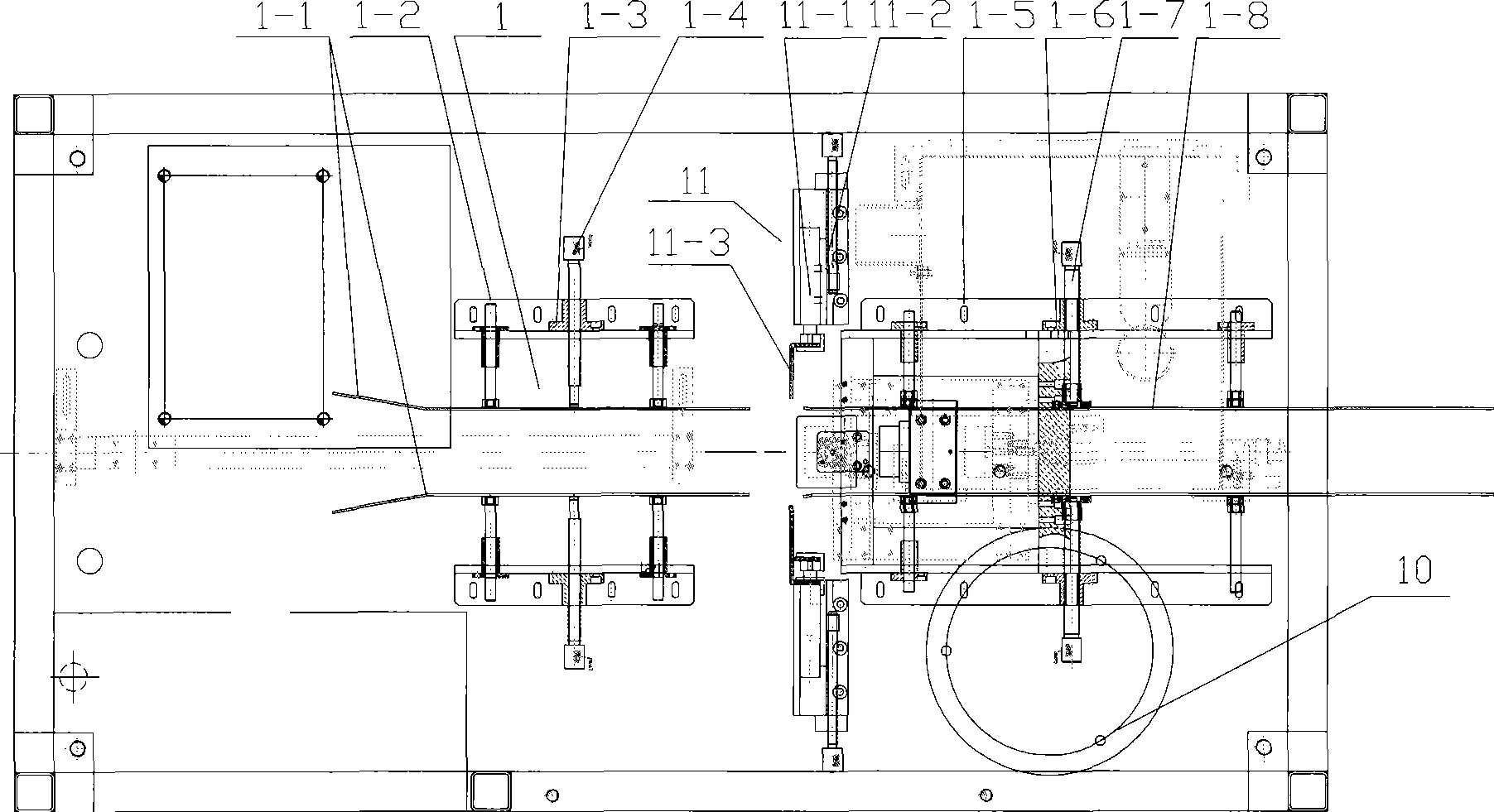

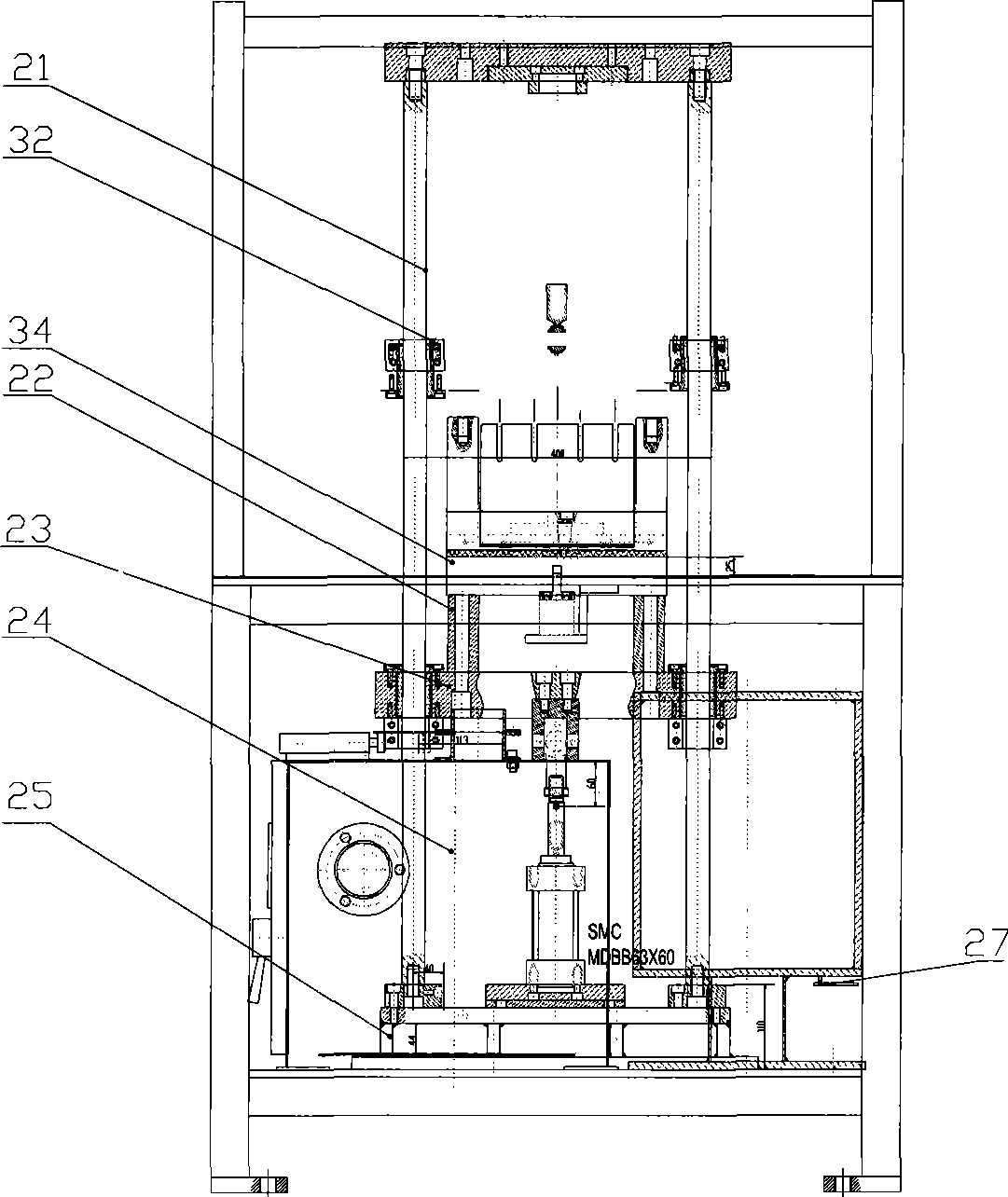

[0012] Example 1: Refer to the attached Figure 1~3 . The sanitary napkin packaging bag sealing machine, which includes the frame 3, the manufacture of the frame 3 is based on the existing technology, please refer to the attached Figure 1~3 It can be implemented, so it will not be described here. The electrical circuit and the control device are in the prior art and will not be described here. The packaging bag channel 1 is located on the work surface of the frame 3 and the packaging bag channel 1 has a cross-shaped through slot. The rodless cylinder pushing mechanism 4 is located on the frame 3 and the rodless cylinder 4-2 drives along the front of the cross-shaped channel. The plate 4-5 reciprocates, the downward cylinder working mechanism 5 is located in the door frame 5-3 above the cross groove, and the lower end of the downward cylinder 5-2 is provided with a hot melt pressure head 5-6 and a cutter 5-10, and a downward direction The upward cylinder working mechanism 9 opposite...

Embodiment 2

[0013] Embodiment 2: On the basis of embodiment 1, the sealing method of the sanitary napkin packaging bag sealing machine, the sanitary napkin packaging bag after the bag is pushed into the sealing packaging structure by the push plate 4-5 in the rodless cylinder pushing mechanism 4, The pressure plate 6-2 in the pneumatic exhaust limit mechanism located above the packaging bag and the upward cylinder 9-4 in the upward cylinder working mechanism 9 drive the bottom plate 9-1 to move upward together to exhaust the air in the packaging bag, and the pneumatic exhaust limit In the positioning mechanism, the limit double cylinder 6 drives the limit plate to move down to limit the position. The two double cylinders 11-1 in the pneumatic angle mechanism 11 respectively drive the two gusset fixing plates 11-2 to be inserted into both sides of the packaging bag in both directions. The two sides of the packaging bag are concave. At this time, the downward cylinder 5-1 in the downward cylind...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com