Asymmetric azo complex dye and manufacturing method thereof

An azo-chromium and asymmetric technology, applied in the field of asymmetric azo-chromium dyes and their preparation methods, can solve the problems of poor color fastness and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

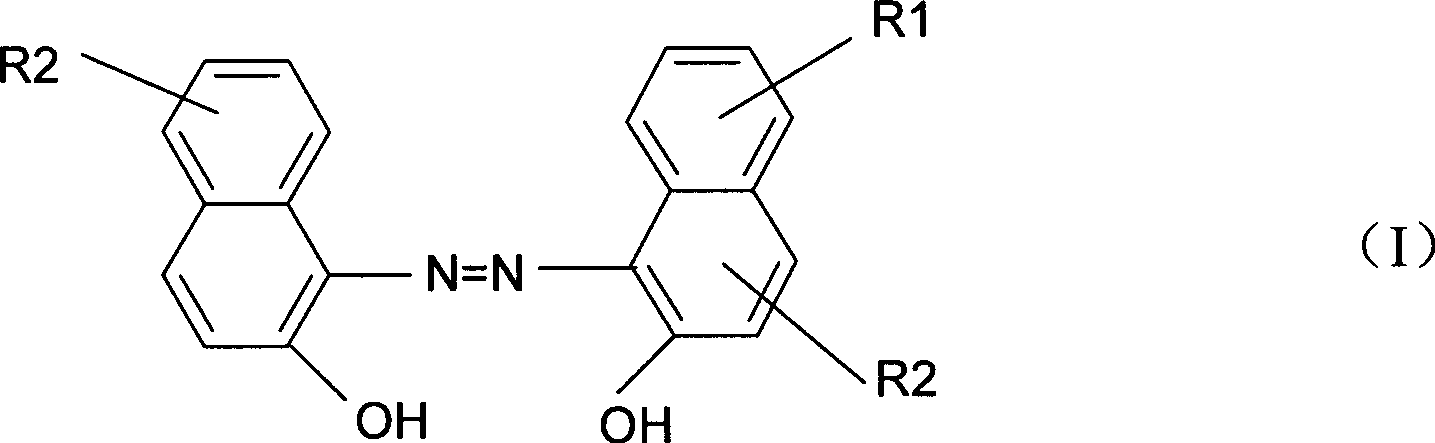

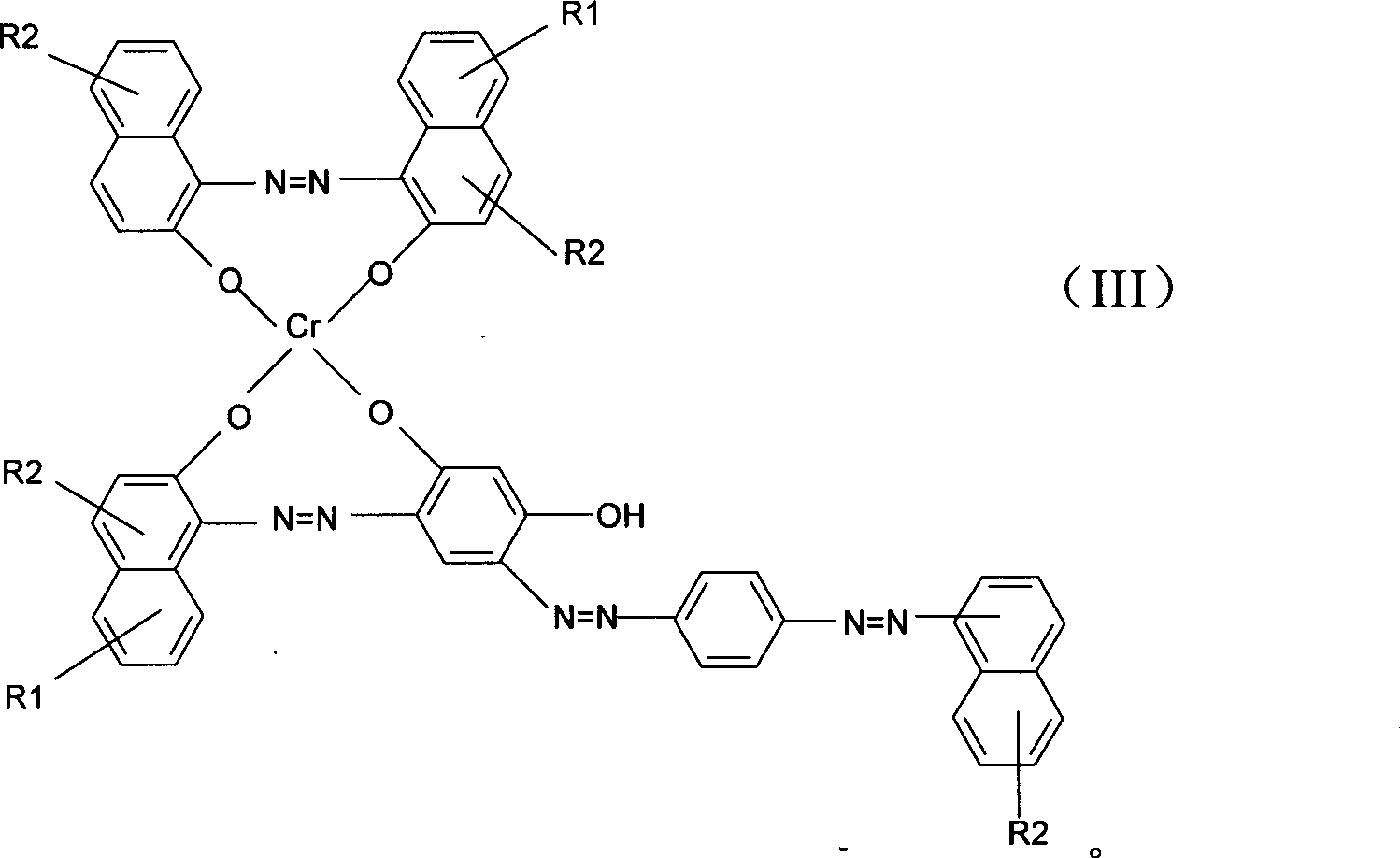

[0012] The asymmetric azochromium dye of the embodiment of the present invention is the azo compound synthesized by the reaction of 6-nitro-1,2-diazooxynaphthalene-4-sulfonic acid and naphthol as the main body. The compound formed by the reaction of aminoazosulfonic acid naphthalene, resorcinol and a diazonium naphthalene compound, and the azo compound forms a chromium complex to obtain the following structure:

[0013]

[0014] Among them, R1 can contain H, NO 2 , R2 contains H, SO 3 H.

[0015] According to the embodiments of the present invention, the preparation method of asymmetric azochrome dyes is described in detail as follows:

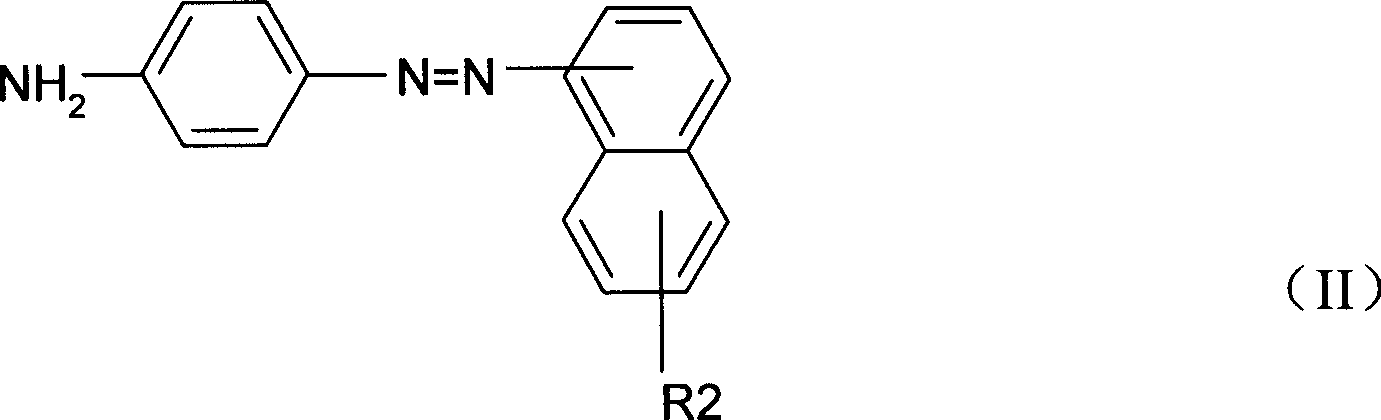

[0016] Synthesis of Azo Compounds

[0017] A diazonium naphthalene compound and naphthol are reacted with an equivalent ratio of 100:105 to obtain an azo compound as shown in chemical formula (I):

[0018]

[0019] According to an embodiment of the present invention, 30 grams of 6-nitro-1,2-diazooxynaphthalene-4-sulfonic acid (1,2-a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com