Patents

Literature

138 results about "Naphthalene Compound" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

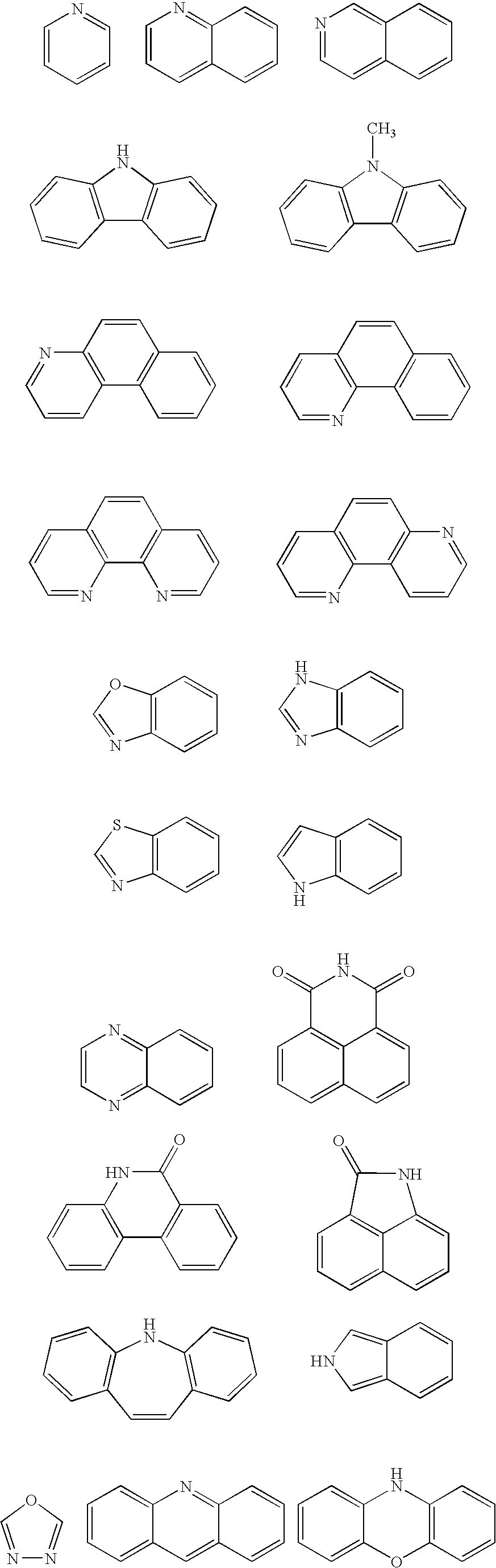

A class of compounds with the basic naphthalene structure, an aromatic hydrocarbon compound, consisting of two fused benzene rings.

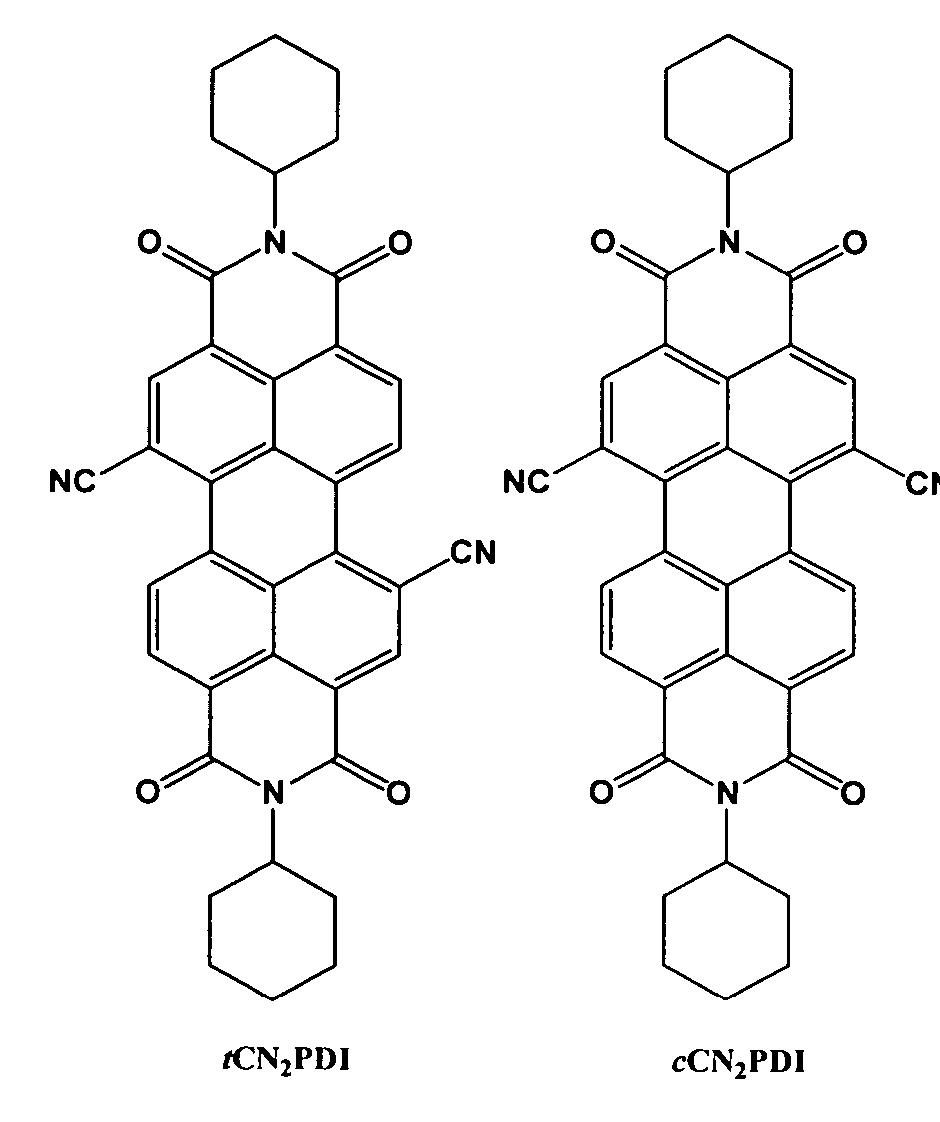

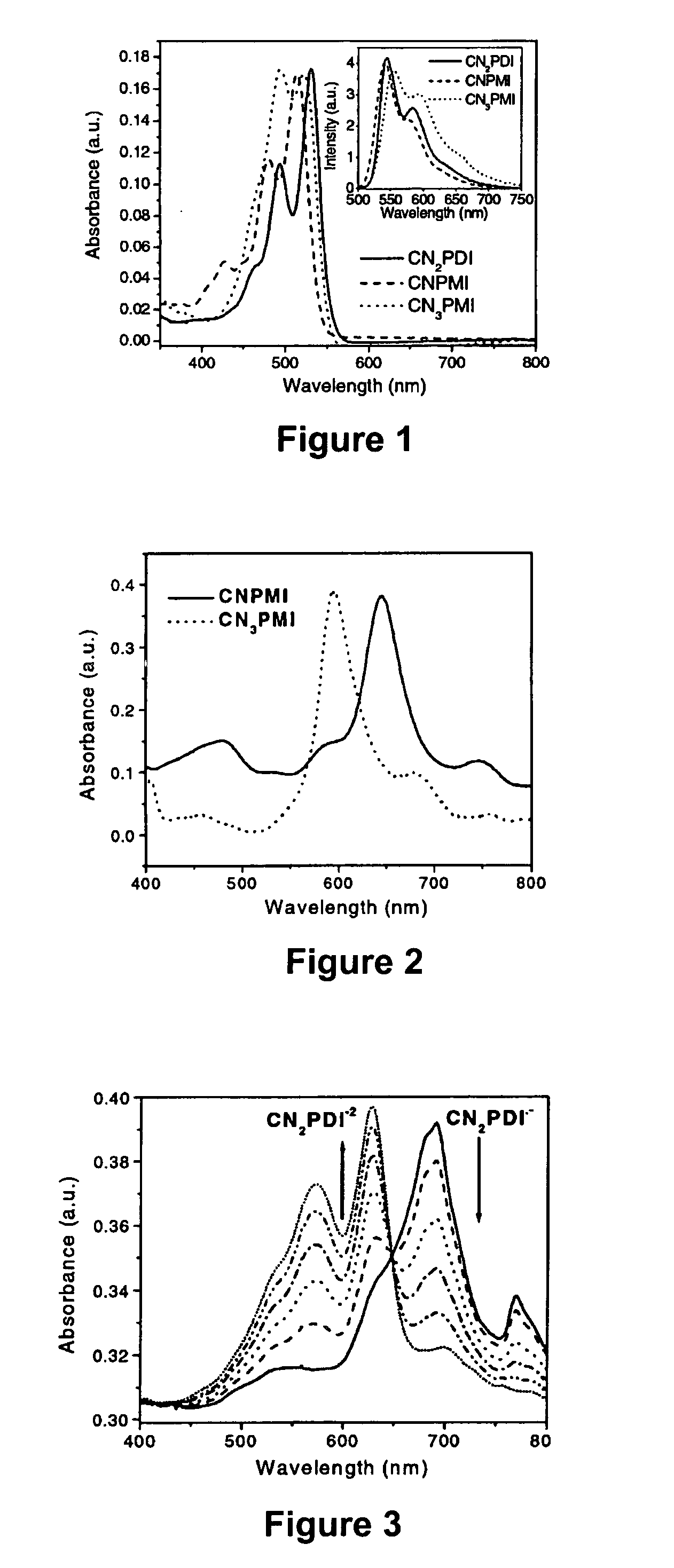

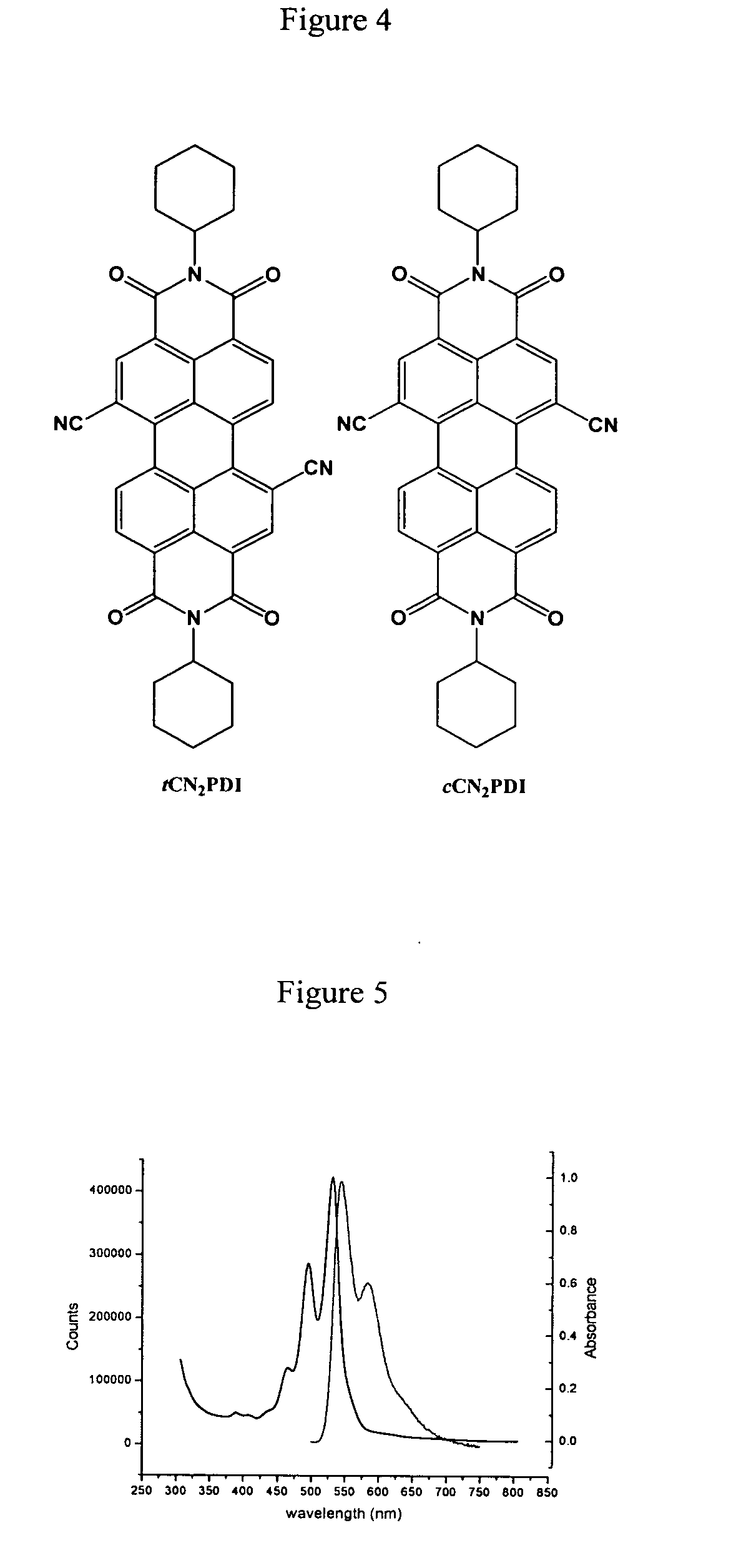

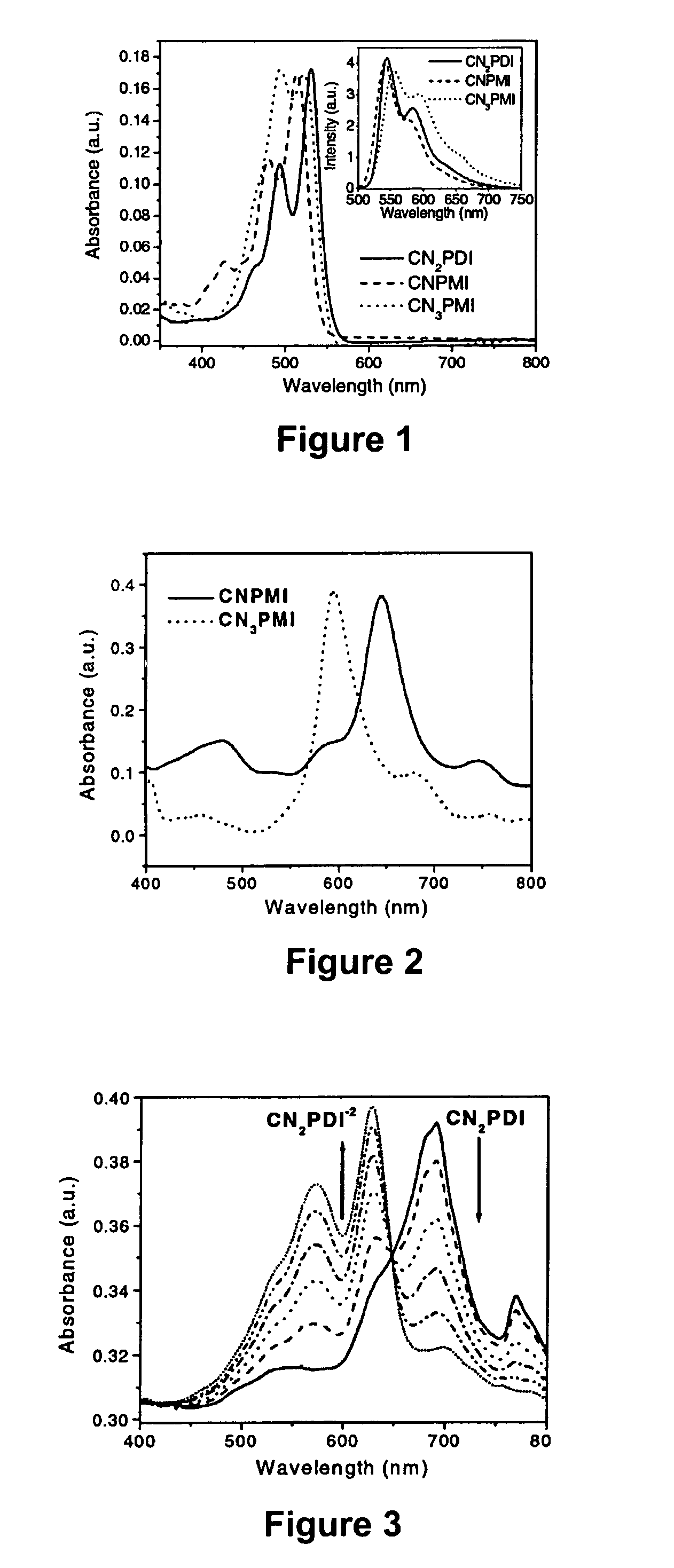

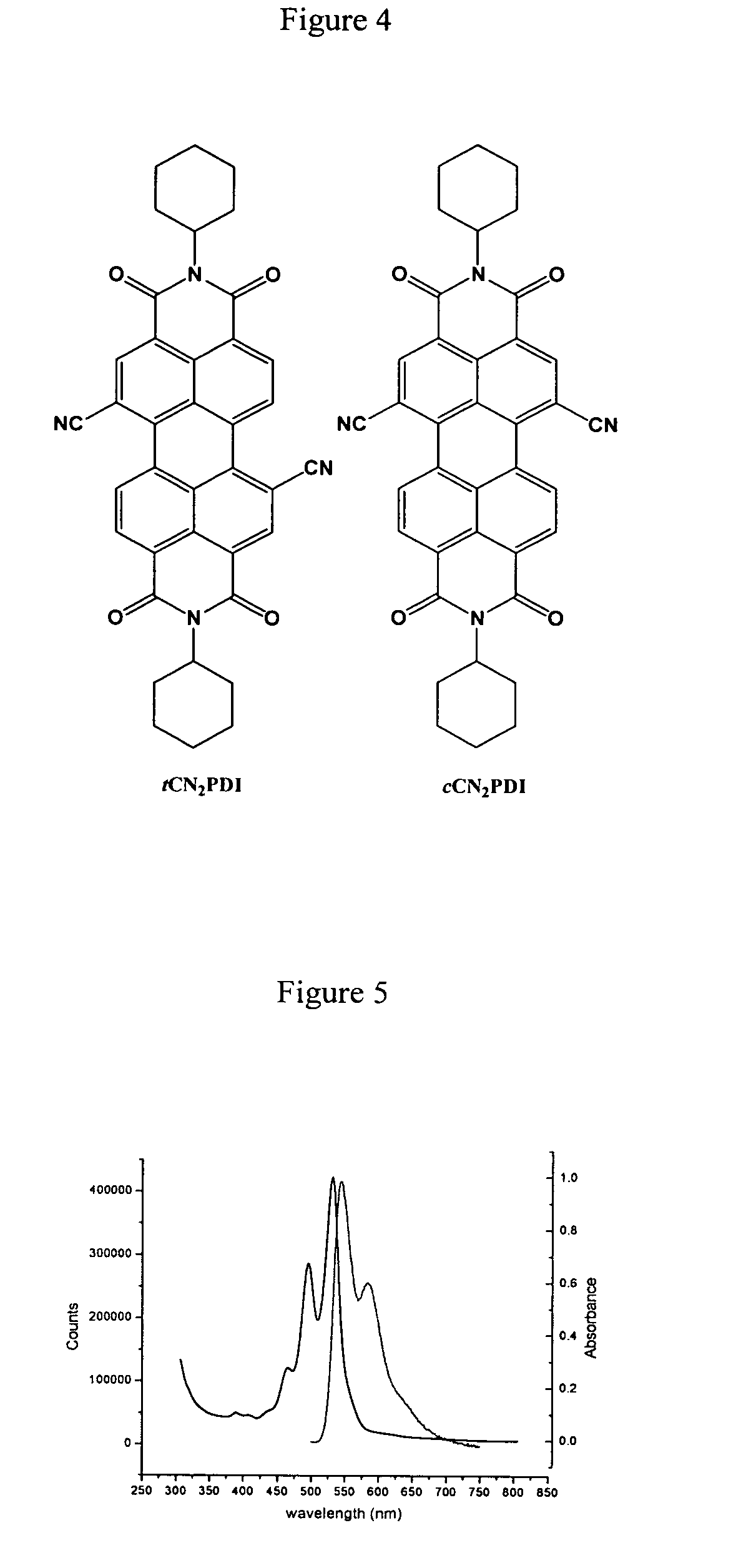

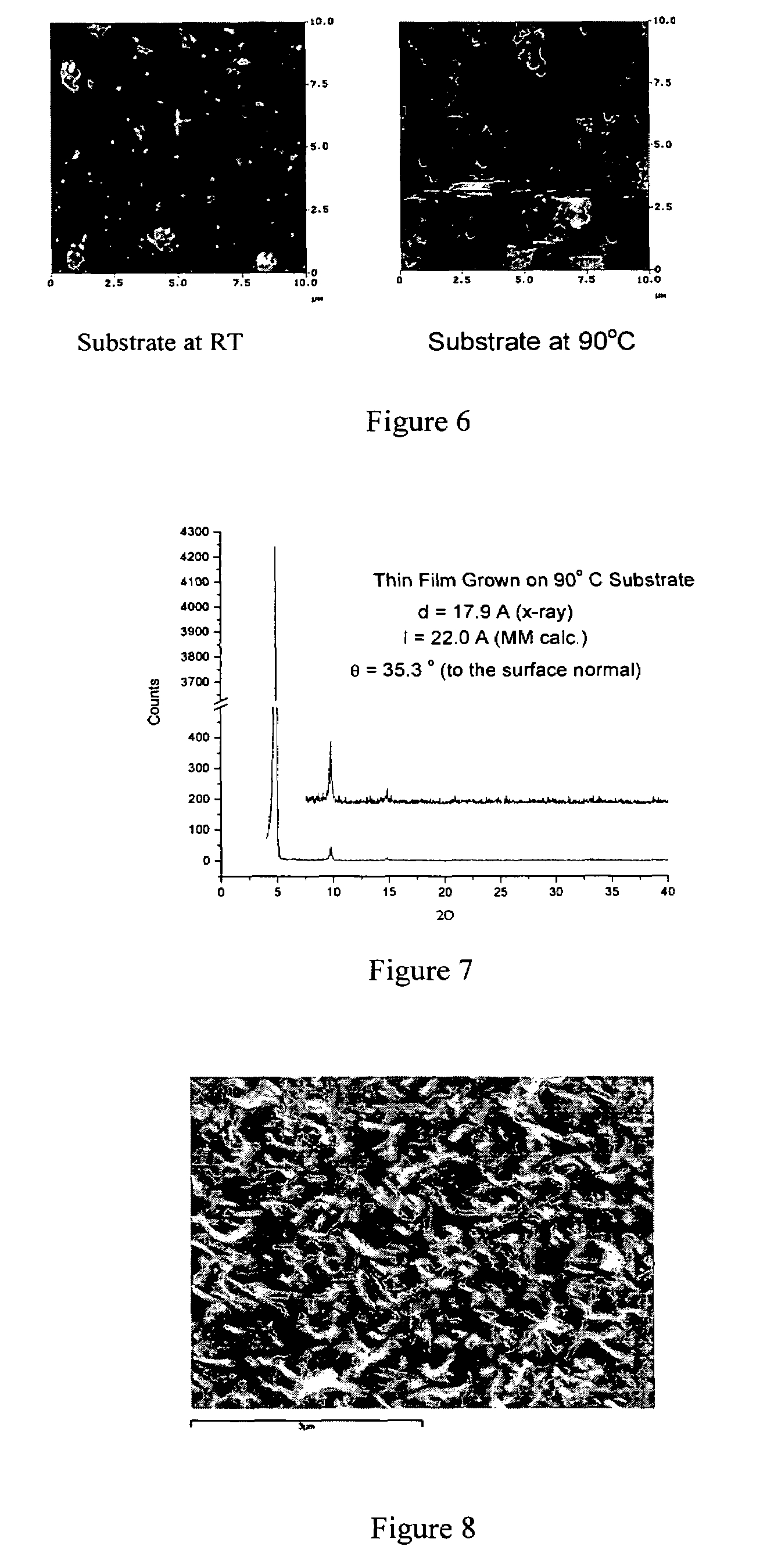

Perylene n-type semiconductors and related devices

ActiveUS20050176970A1Improve solubilityImproved radical anion stabilityOrganic chemistryNaphthalimide/phthalimide dyesPeryleneElectron

Mono- and diimide perylene and naphthalene compounds, N- and core-substituted with electron-withdrawing groups, for use in the fabrication of various device structures.

Owner:DARPA

Perylene n-type semiconductors and related devices

ActiveUS7671202B2Improve Oxidation StabilityReduction potential(s)Organic chemistryNaphthalimide/phthalimide dyesPeryleneSemiconductor

Mono- and diimide perylene and naphthalene compounds, N- and core-substituted with electron-withdrawing groups, for use in the fabrication of various device structures.

Owner:DARPA

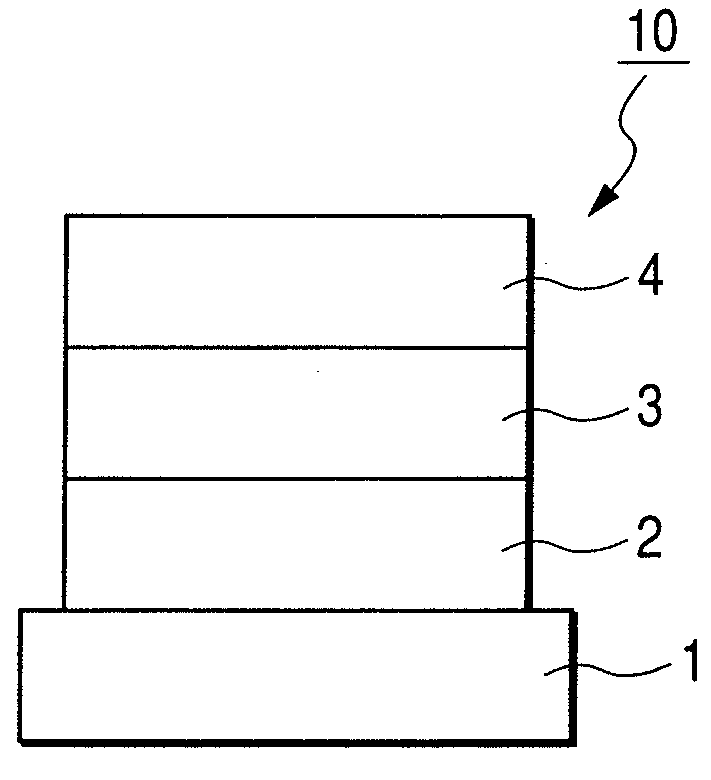

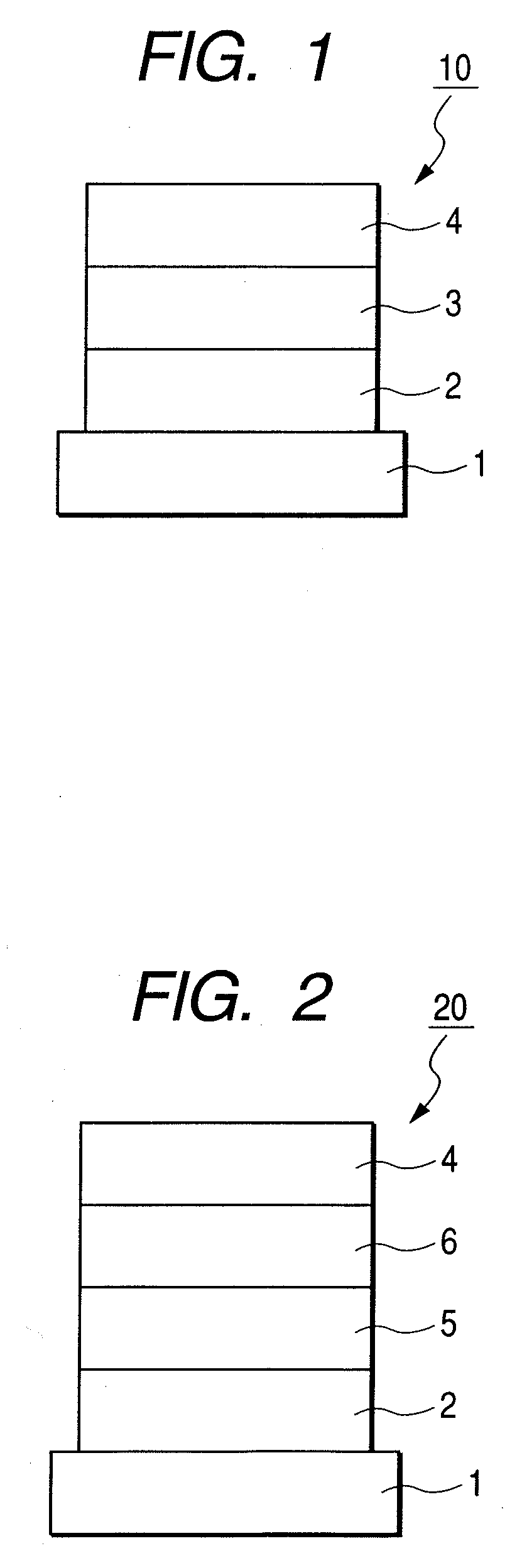

Naphthalene compound and organic light-emitting device using the compound

InactiveUS20080224603A1Improve efficiencyIncreased durabilityOrganic chemistryDischarge tube luminescnet screensSimple Organic CompoundsOrganic light emitting device

There is provided an organic light-emitting device having an optical output with a high a high efficiency and a high luminance, and having good durability. The organic light-emitting device includes an anode, a cathode, and a layer including an organic compound interposed between the anode and the cathode, in which the layer contains a naphthalene compound represented by the general formula (1):wherein Ar1's each represent a substituted or unsubstituted fused ring aromatic hydrocarbon group having four or more rings.

Owner:CANON KK

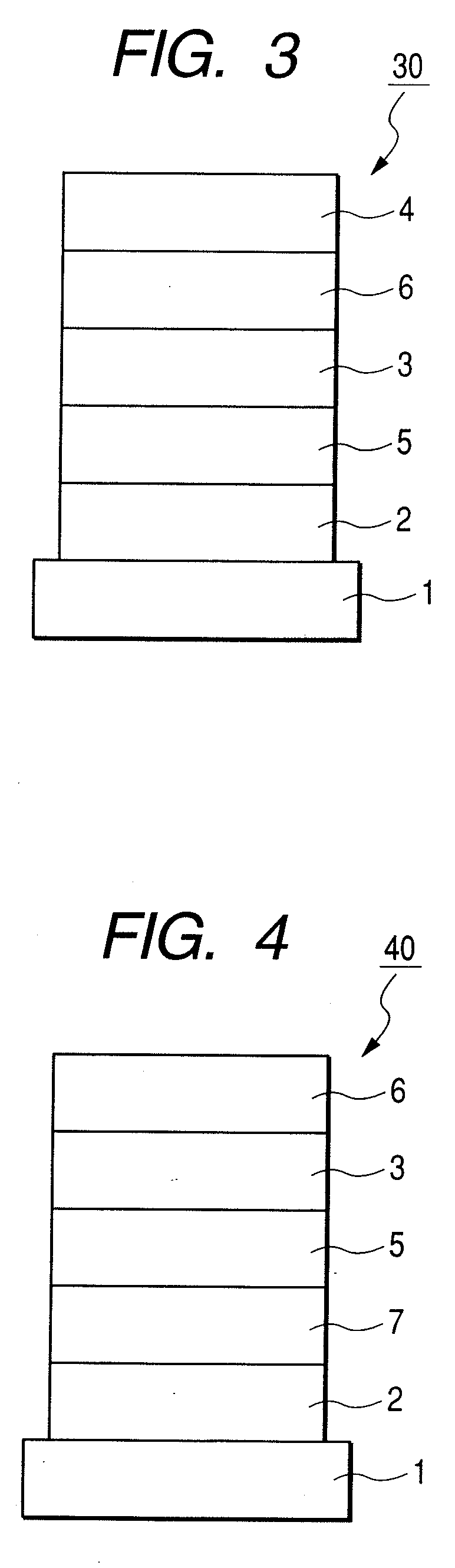

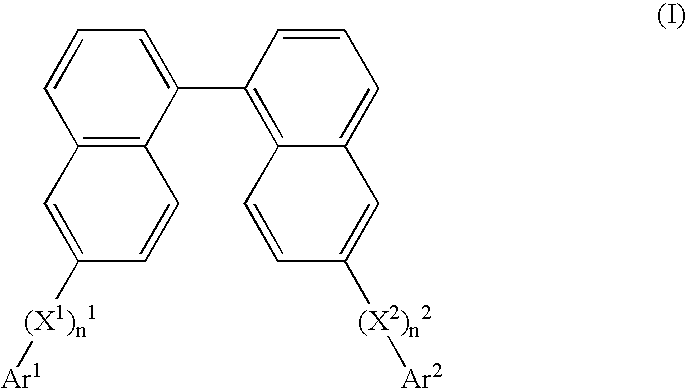

Binaphthol based chromophores for the fabrication of blue organic light emitting diodes

A blue electroluminescent material based on a binaphtyl compound of the general formula (I). Particular embodiments having the general formula have good solubilities in common organic solvents, resist crystallization and can be sublimed in a device fabrication process. These properties enable the fabrication of organic electroluminescent devices.

Owner:RGT UNIV OF CALIFORNIA

Naphthalene compounds

Compound of formula (I): wherein: T represents alkylene, A and B together form a naphthalene, dihydronaphthalene, or tetrahydronaphthalene group, R represents hydrogen, hydroxy, R' or OR', R' being as defined in the description, G1 represents halogen, a radical R1 or a group -O-CO-R1, R1 being as defined in the description, G2 represents a group selected from: X, R2 and R21 being as defined in the description, and medicinal products containing the same which are useful in the treatment of a condition related to the melatoninergic system.

Owner:LES LAB SERVIER

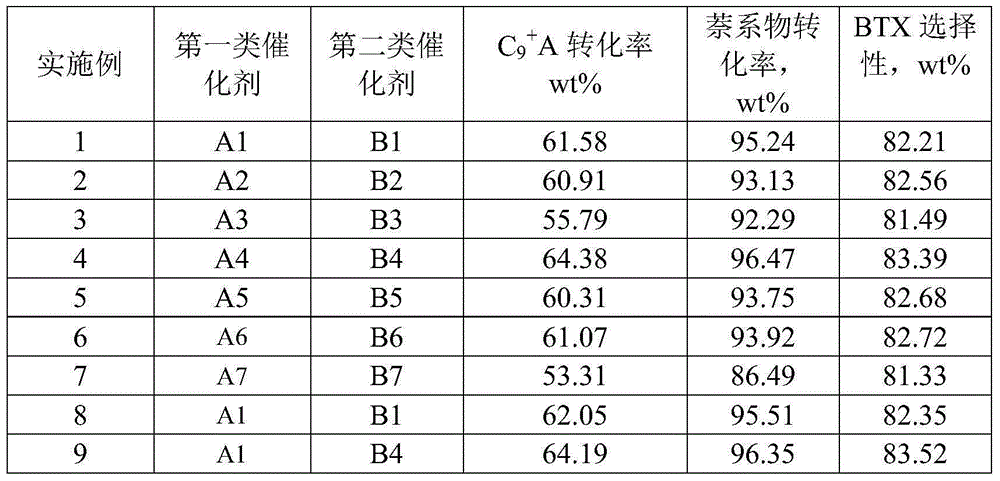

Method for increasing yield of xylene through lightening of heavy aromatic hydrocarbons

ActiveCN106588533AEfficient use ofIncrease profitMolecular sieve catalystsHydrocarbonsAlkyl transferHydrogen

The invention relates to a method for increasing the yield of xylene through lightening of heavy aromatic hydrocarbons and mainly solves the problem that heavy aromatic hydrocarbon raw materials containing naphthalene compounds cannot be effectively treated with an existing alkyl transfer technique. By means of the method for increasing the yield of xylene through lightening of heavy aromatic hydrocarbons, effluents containing rich benzene, methylbenzene and xylene are produced from C9<+> heavy aromatic hydrocarbons containing the naphthalene compounds and taken as raw materials through two metal-supporting catalysts in the presence of hydrogen, the technical problem is solved better, and the method can be used for industrial production aiming at increasing the yield of xylene through lightening of the aromatic hydrocarbons.

Owner:CHINA PETROLEUM & CHEM CORP +1

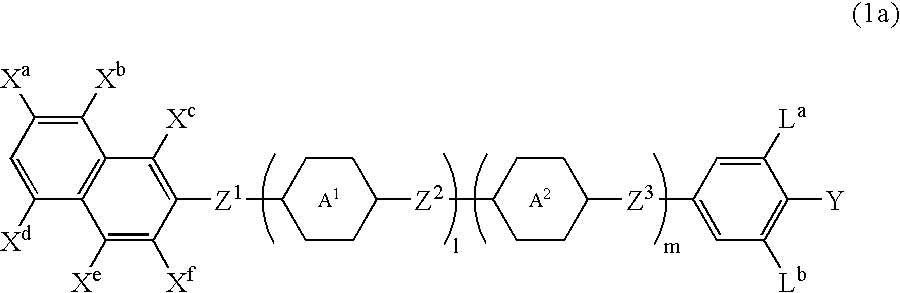

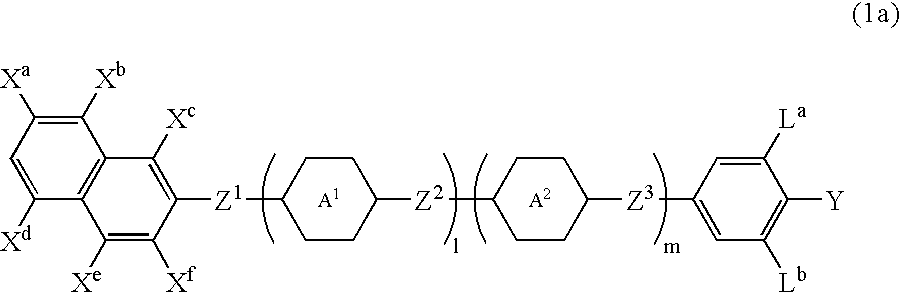

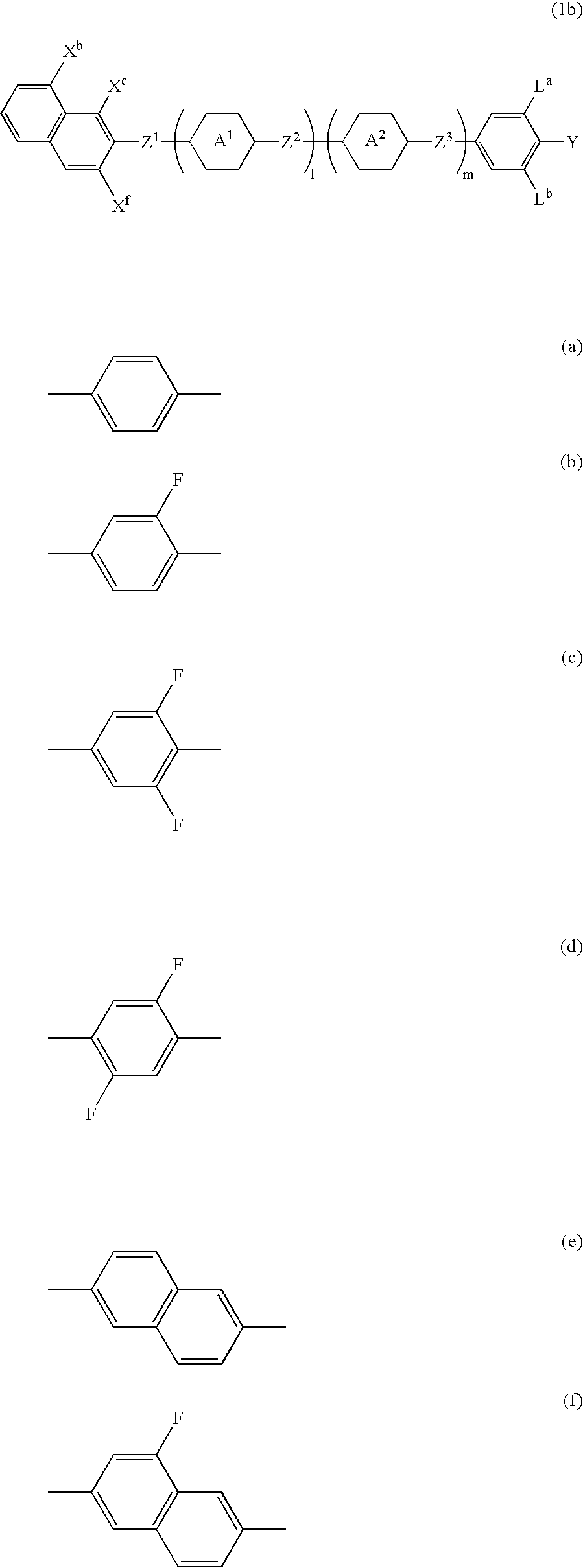

Naphthalene compound with terminal hydrogen, liquid crystal composition including the compound, and LCD device including the liquid crystal composition

InactiveUS20070051919A1Maintain good propertiesReduce the driving voltageLiquid crystal compositionsOrganic chemistryHalogenDielectric anisotropy

A liquid crystal (LC) compound having generally required physical properties, low viscosity, proper optical anisotropy, proper dielectric anisotropy and good compatibility with other LC compounds is described. An LC composition including the compound and an LCD device including the composition are also described. The compound is expressed by formula (1a): wherein the ring A1 and the ring A2 are independently 1,4-phenylene, pyridine-2,5-diyl, pyrimidine-2,5-diyl or naphthalene-2,6-diyl, in which any hydrogen can be replaced by halogen; Z1, Z2 and Z3 are independently a single bond, —(CH2 )2—, —(CH2 )4—, —CH═CH—, —C≡C—, —CF2O—, —OCF2—, —COO— or —OCO—; Xa, Xb, Xc, Xd, Xe and Xf are independently hydrogen or fluorine; Y is —OCH2F, —OCHF2, —OCF3, —SCH2F, —SCHF2, —SCF3, —CH2F, —CHF2, —CF3, fluorine or chlorine; La and Lb are independently hydrogen or fluorine; and “l” and “m” are independently equal to 0 or 1.

Owner:JNC CORP +1

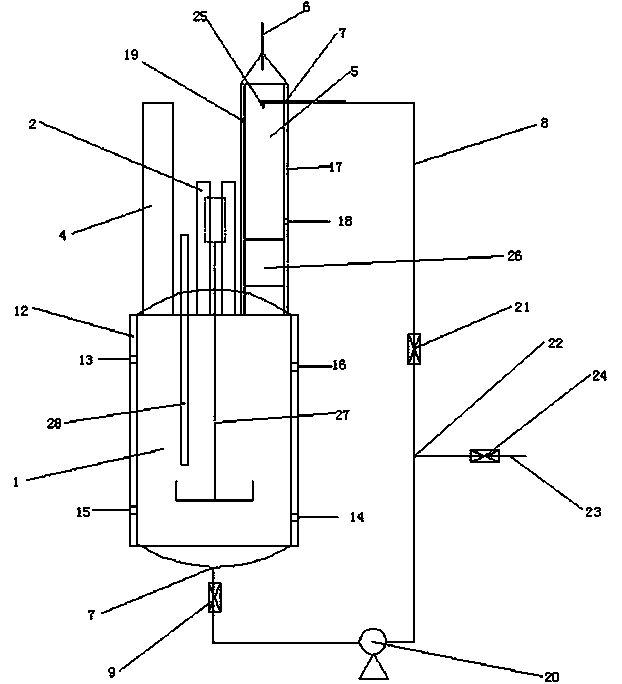

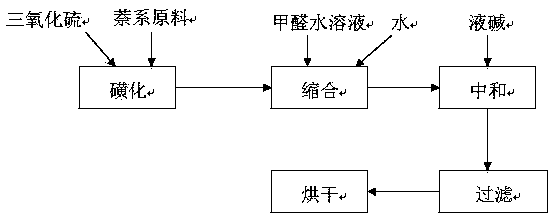

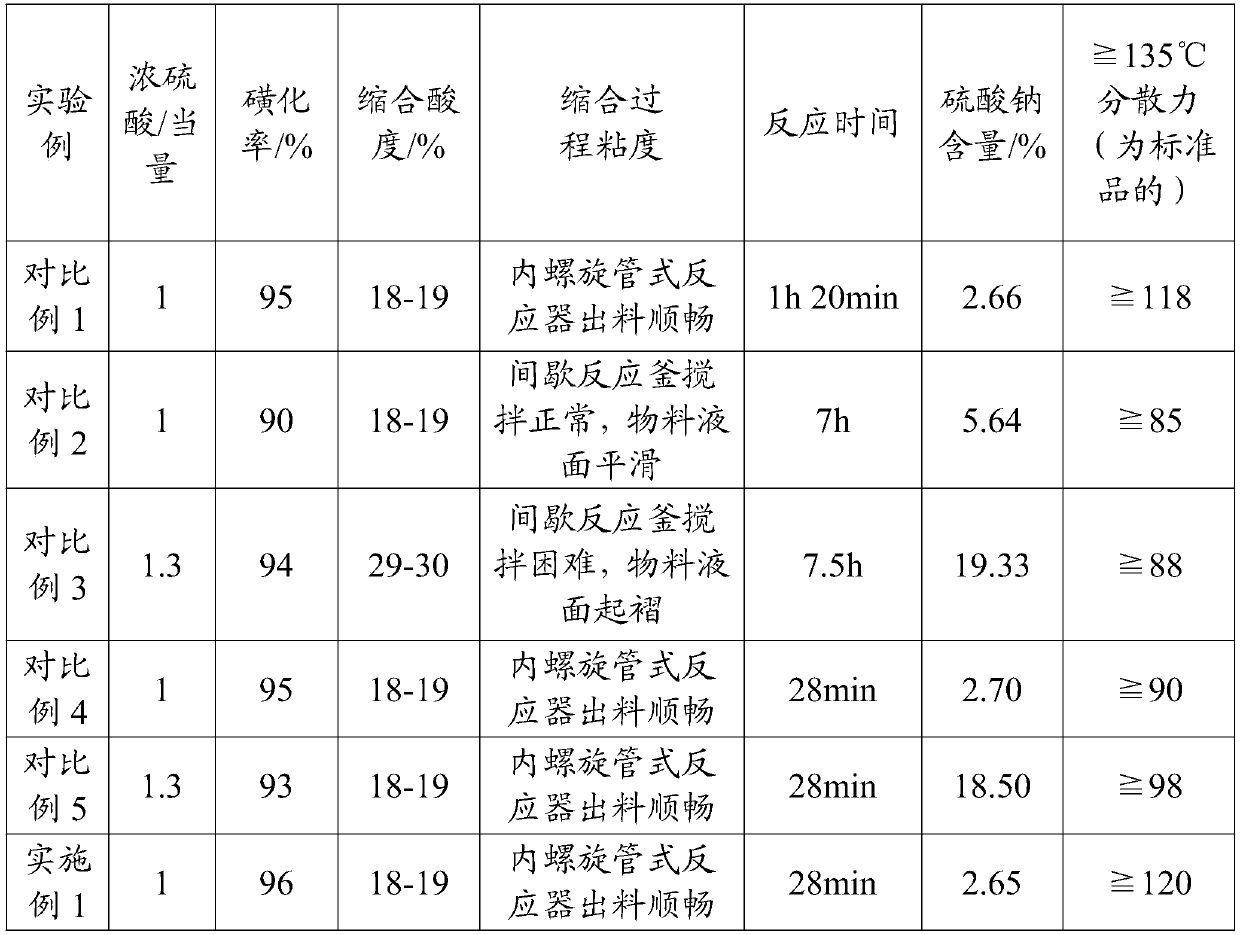

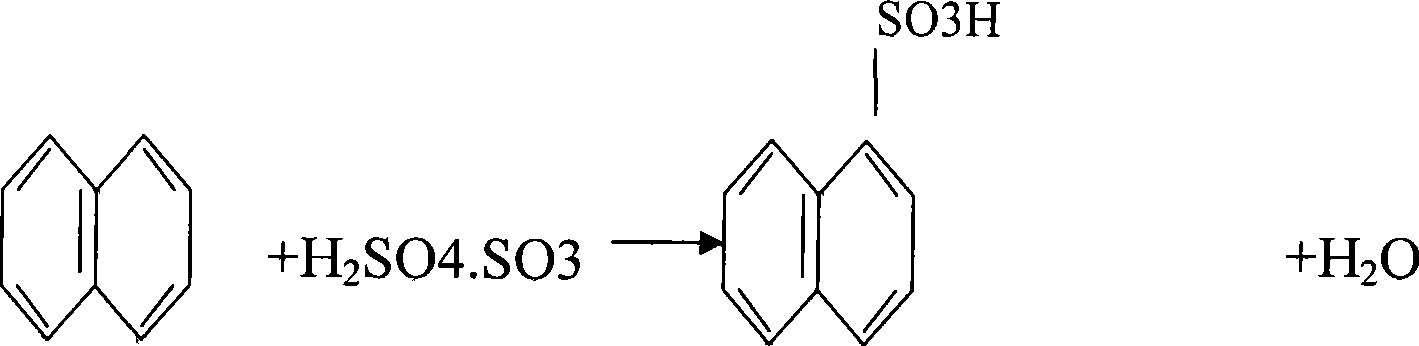

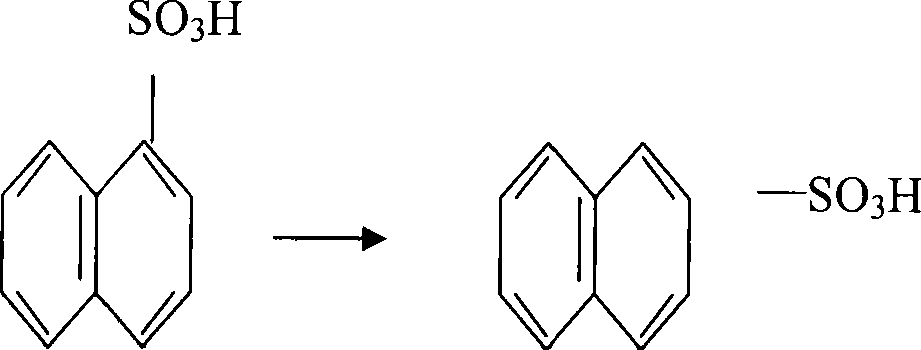

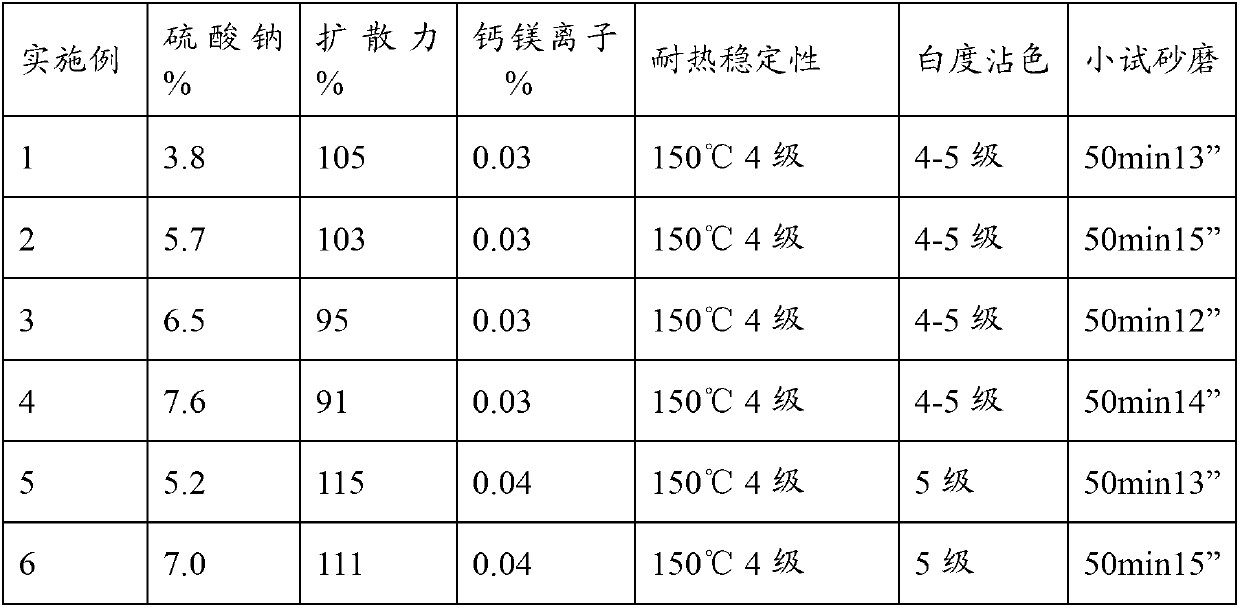

Sulfonating technique for producing dye dispersant MF (melamine-formaldehyde)

ActiveCN102746196ANo pollutionReduce dosageSulfonic acids salts preparationSulfonic acid preparationMelamine formaldehydeStaining

The invention relates to a production technique of a dye dispersant MF (melamine-formaldehyde), which comprises the following steps: adding concentrated sulfuric acid into a naphthalene compound, introducing sulfuric anhydride at the temperature of not higher than 80 DEG C to carry out reaction, heating the temperature of the system to 130-160 DEG C, carrying out reaction while keeping the temperature, and adding formaldehyde to carry out condensation; and after the condensation finishes, adding an alkali to regulate the pH value to neutral, thereby obtaining the dispersant MF, wherein the naphthalene compound / sulfuric acid / sulfuric anhydride mol ratio is 1:(0.2-0.4):(0.8-1). The dispersant MF produced by the technique provided by the invention has the advantages of high heat stability, favorable whiteness staining and short sanding time.

Owner:ZHEJIANG RUNTU

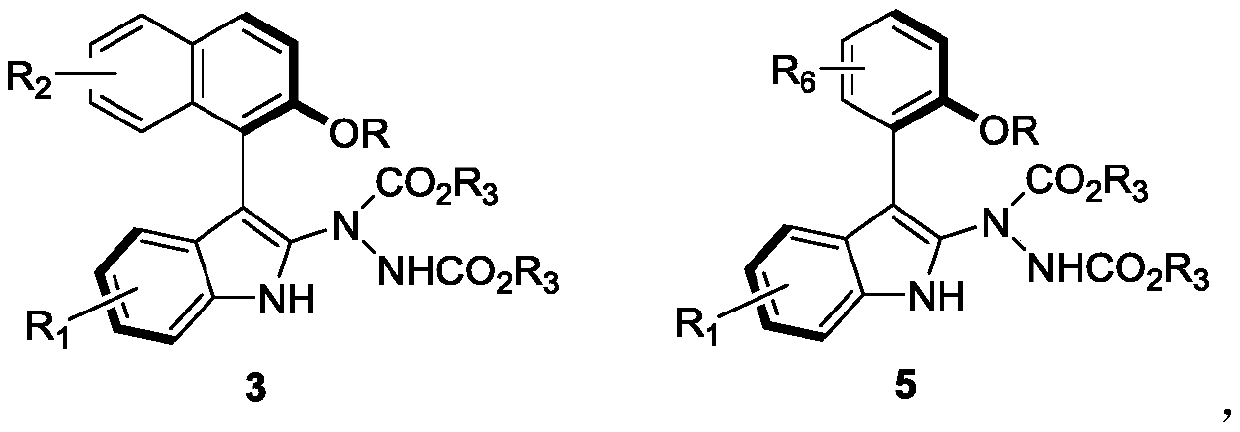

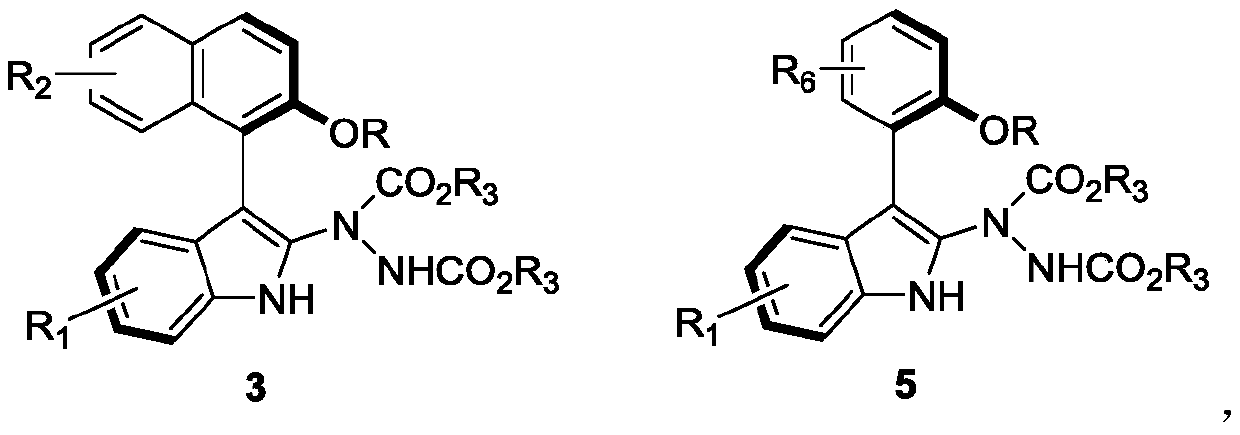

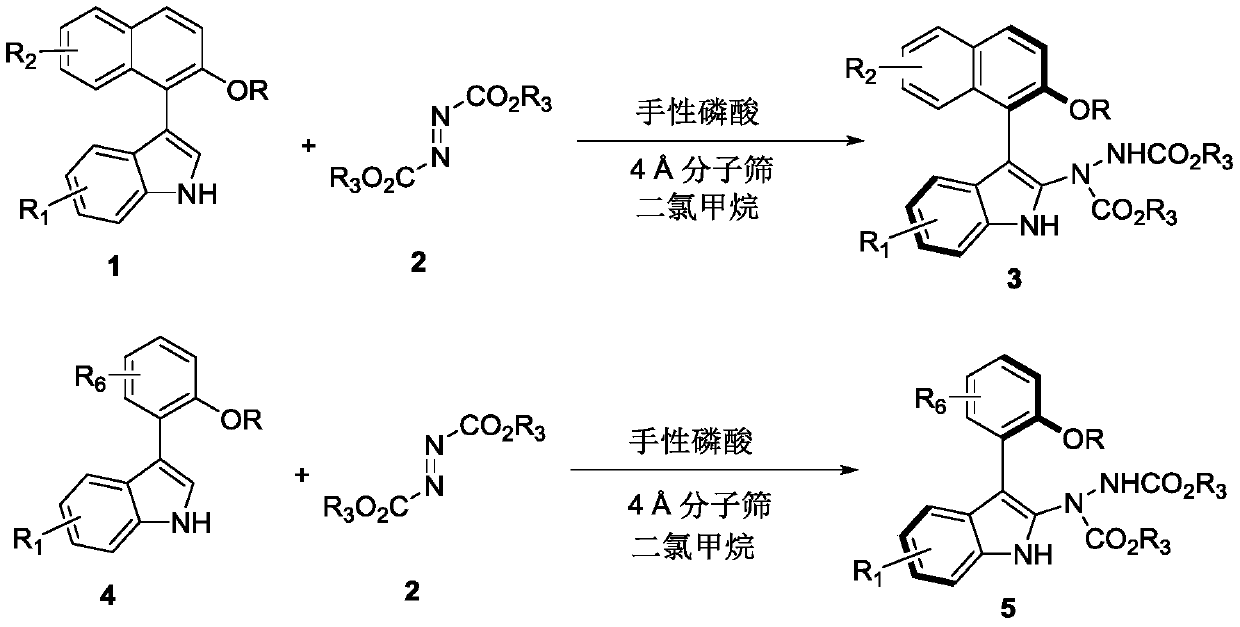

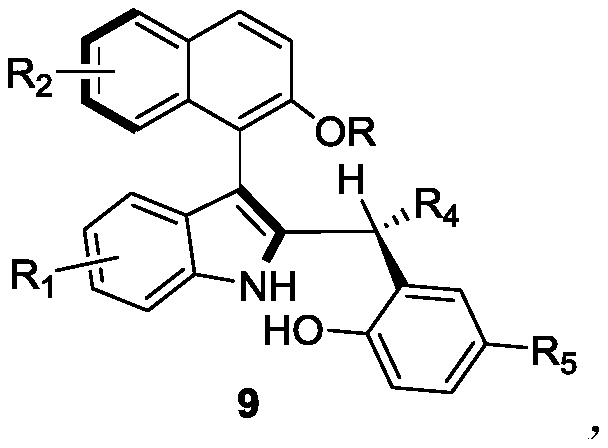

Axially chiral aryl indole compound and synthesis method thereof

ActiveCN110467555AGain diversityGain complexityOrganic active ingredientsOrganic chemistry methodsChemical structureSynthesis methods

The invention discloses an axially chiral aryl indole compound and a synthesis method thereof, wherein the compound has a chemical structure formula represented by a formula 3 or formula 5. The synthesis method comprises: using a compound represented by a formula 1 or a compound represented by a formula 4 and a compound represented by a formula 2 as reaction raw materials, using dichloromethane asa solvent, adding a molecular sieve, carrying out a stirring reaction under the action of a chiral phosphoric acid catalyst, tracking through TLC until the reaction is completely performed, filtering, concentrating, and purifying to prepare the product. According to the present invention, the test results of the biological activity of the compounds show that the compound has a certain cytotoxic activity on MCF-7 breast cancer cells; the synthesis method has advantages of simple operation, mild reaction conditions and economical and easily available raw materials; and the prepared axially chiral indole-naphthalene compound and the prepared indole-benzene compound have high optical purity, and are widely used in the field of pharmaceutical research and development.

Owner:XUZHOU NORMAL UNIVERSITY

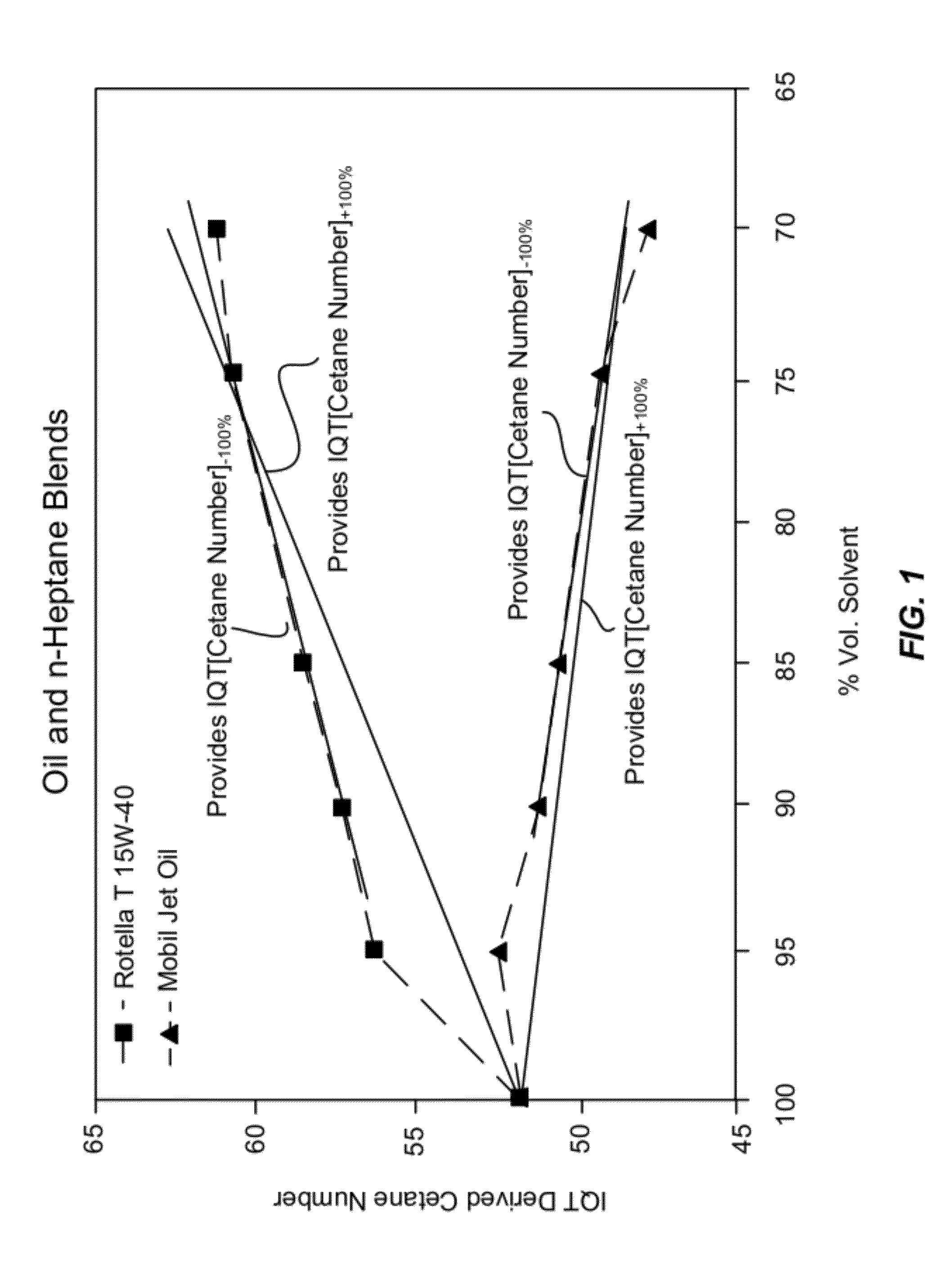

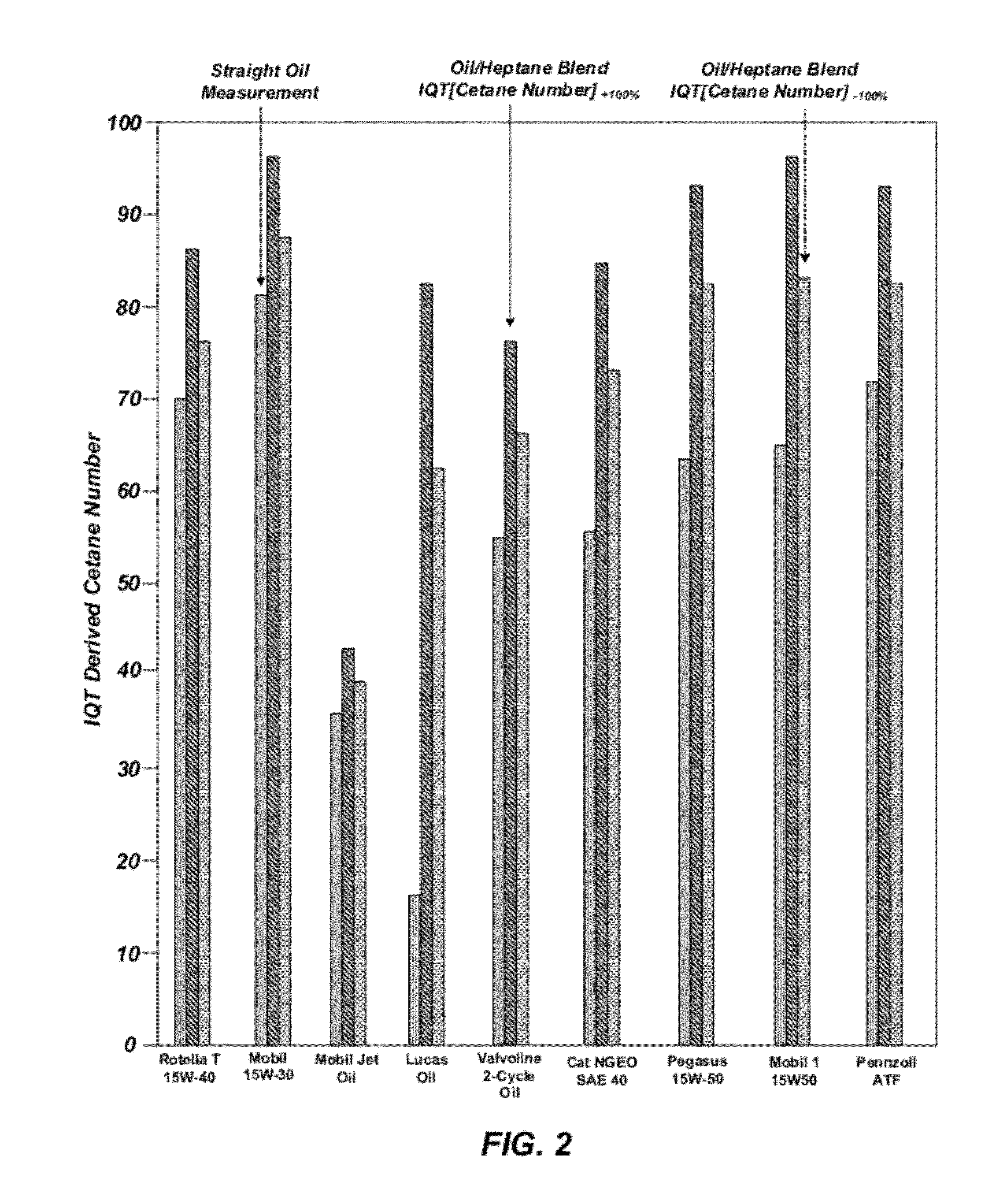

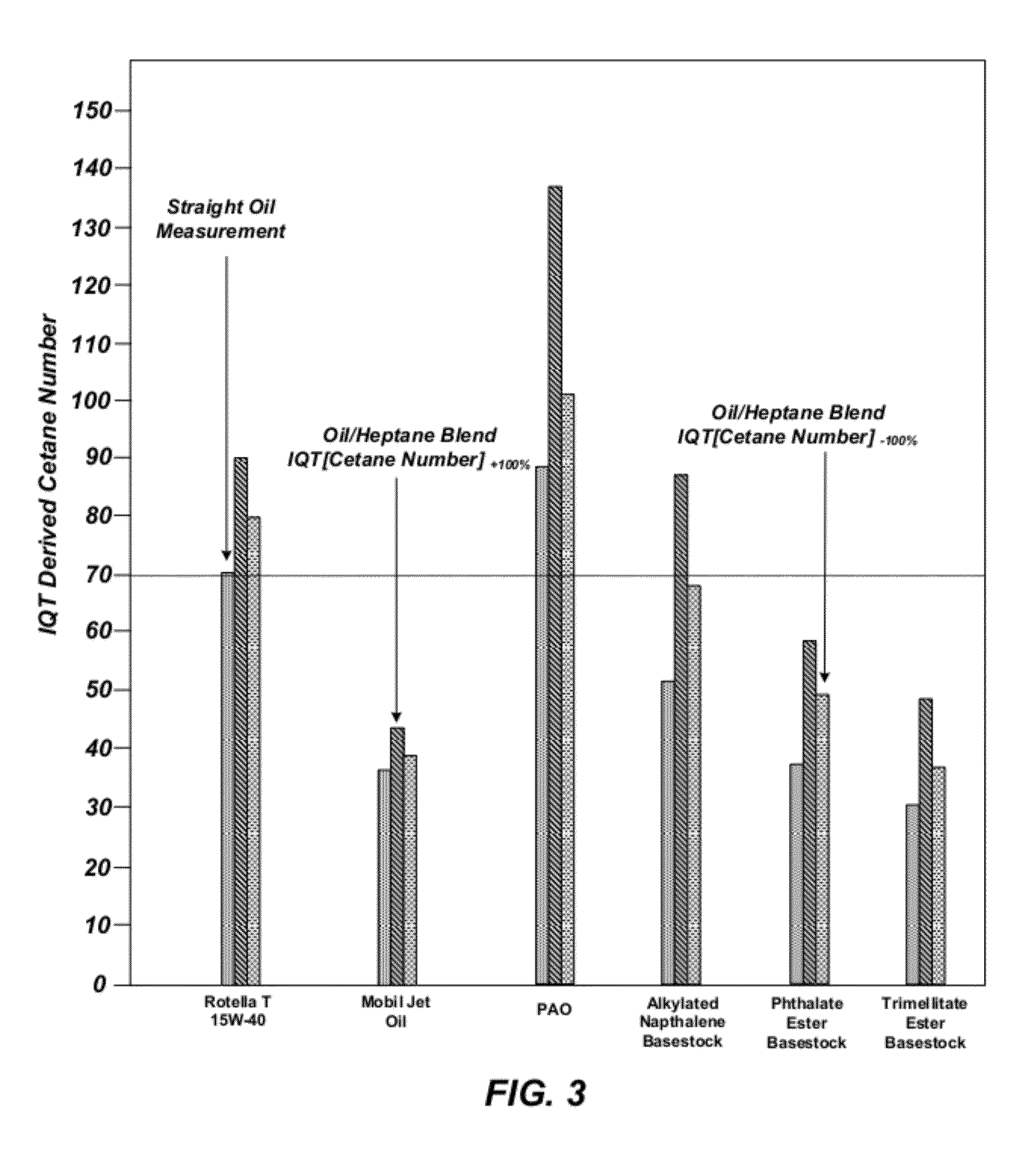

Lubricant oil compositions to optimize internal combustion engine performance

The present disclosure relates to lubricant oil compositions formed from base stock oils to optimize internal combustion engine performance. Base stock oils are identified that have selected cetane number characteristics and relatively reduced reactivity to improve their associated combustion characteristics and reduce engine knock without the need to modify the engine fuel or engine parameters such as compression ratio and / or ignition timing. The base stocks may specifically include esters of dicarboxylic acids, esters of trimellitic anhydride and / or alklyated naphthalene compounds.

Owner:SOUTHWEST RES INST

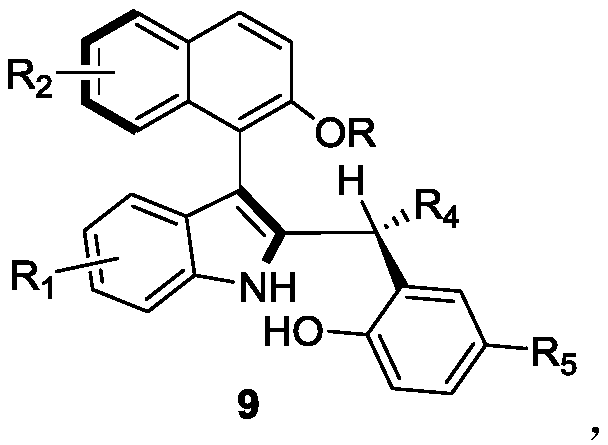

Axially-chiral indole-naphthalene compounds and preparation method thereof

ActiveCN110452150AHigh yieldControlling enantioselectivityOrganic chemistry methodsOrganic-compounds/hydrides/coordination-complexes catalystsXylyleneChemical structure

The invention discloses axially-chiral indole-naphthalene compounds and a preparation method thereof. The axially-chiral indole-naphthalene compounds have a chemical structure represented by a formula9 shown in the description; and the method comprises the following steps: a compound represented by a formula 7 and a compound represented by a formula 8 are used as reaction raw materials, a mixed solution of 1,1,2,2-tetrachloroethane and p-xylene is used as a solvent, a molecular sieve is added, a reaction is performed under stirring under the action of a chiral phosphoric acid catalyst, the reaction is tracked by TLC until the reaction is completed, filtration is performed, concentration is performed, purification is performed, and therefore one compound is obtained. The method for preparing the axially-chiral indole-naphthalene compounds provided by the invention is an asymmetric addition reaction under catalysis of organic small molecules, starts from the racemic raw material to construct the axially-chiral indole-naphthalene structure in one step, and has the advantages of simple and convenient operation, mild reaction conditions and economical easily-available raw materials, and the prepared axially-chiral indole-naphthalene compounds have high optical purity; and the axially-chiral indole-naphthalene compounds prepared by the method are expected to be widely used in the field of asymmetric catalysis.

Owner:XUZHOU NORMAL UNIVERSITY

Intermediate-phase asphalt stock with superior spinning performance and preparation method

InactiveCN104152168AImprove performanceImprove spinnabilityWorking-up pitch/asphalt/bitumen by distillationWorking-up pitch/asphalt/bitumen by chemical meansHydrogen fluorideFiber

The invention relates to an intermediate-phase asphalt stock with superior spinning performance and a preparation method. The method comprises the following steps: performing a polymerization reaction on a naphthalene compound serving as a raw material in the presence of hydrogen fluoride and boron trifluoride serving as catalysts, wherein the using amount of the hydrogen fluoride is 0.5-15 times the mole number of the raw material, the using amount of the boron trifluoride is 0.2-1.0 time the mole number of the raw material, and the polymerization reaction temperature is 250-300 DEG C; after the polymerization reaction ends, removing HF-BF3 serving as a catalyst; distilling an obtained product under reduced pressure under the condition that the temperature is 400 DEG C and the pressure intensity is below 1KPa; and separating a low-boiling-point product out to obtain an intermediate-phase asphalt stock product. Compared with the prior art, intermediate-phase asphalt has the characteristics of superior spinning performance and small quantity of low molecular volatile matters in a spinning process. The preparation method contributes to long-term stable performance of spinning operation, is suitable for industrial production, and meanwhile contributes to the preparation of high-performance asphalt-based carbon fibers.

Owner:SHANGHAI JIAO TONG UNIV

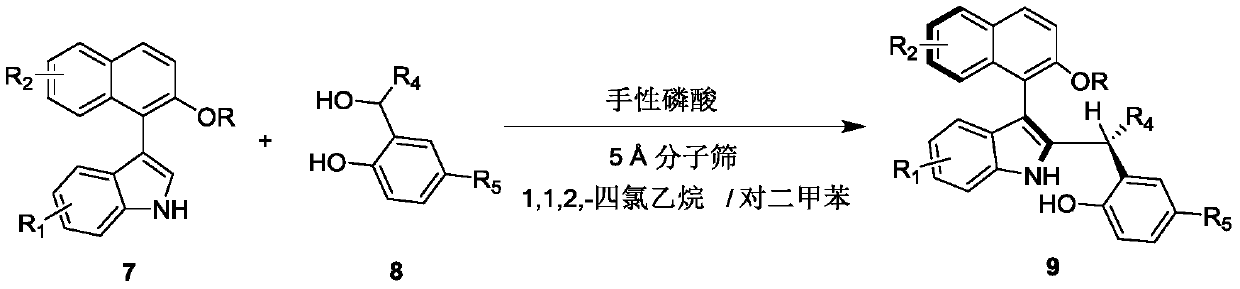

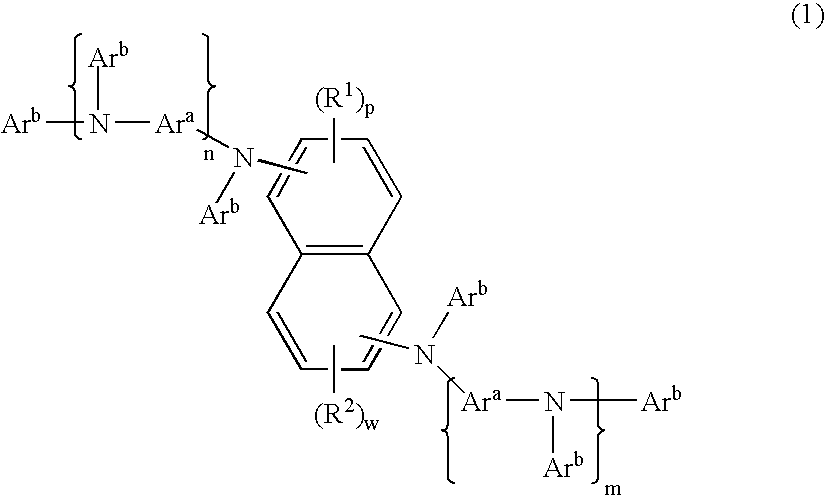

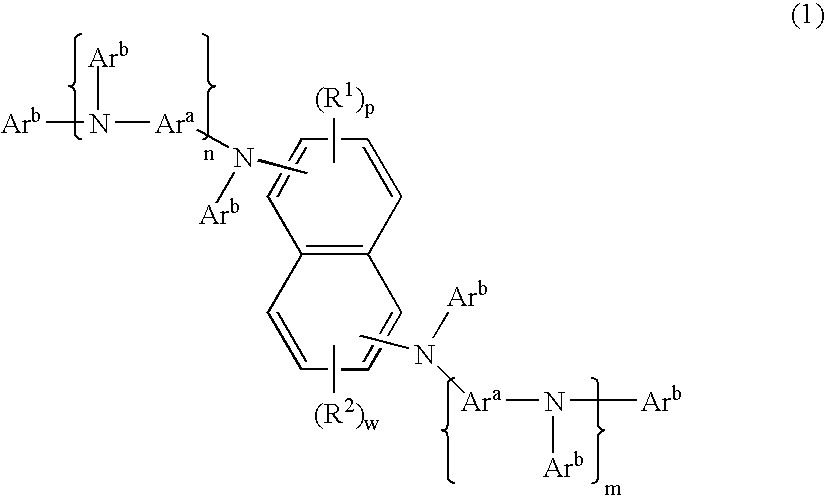

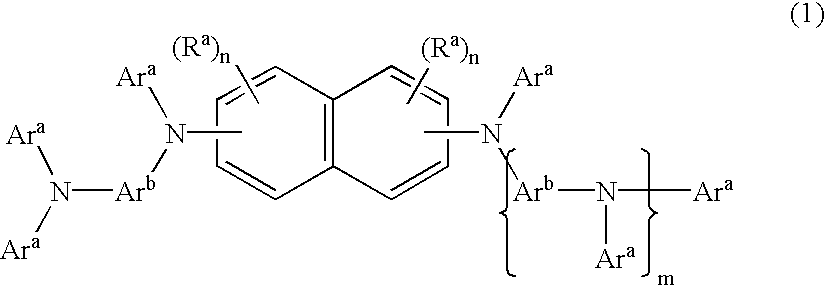

Organic element for electroluminescent devices

InactiveUS20050214567A1Increase brightnessNeed long operating lifetimesIncadescent screens/filtersDischarge tube luminescnet screensNitrogenPhotochemistry

An electroluminescent device comprises a layer containing a naphthalene compound represented by Formula (1), wherein: each R1 and R2 represents an independently selected substituent provided that adjacent substituents may join to form a ring; p and w independently are 0-3; the amine nitrogens on the naphthalene nucleus are located on separate rings; m and n independently are 0, 1 or 2; each Arb represents an independently selected aromatic group; and each Ara represents an independently selected phenylene, biphenylene or naphthalene group; provided that at least one R1 or R2 substituent of the naphthalene compound represented by Formula (1) is a sterically bulky substituent.

Owner:EASTMAN KODAK CO

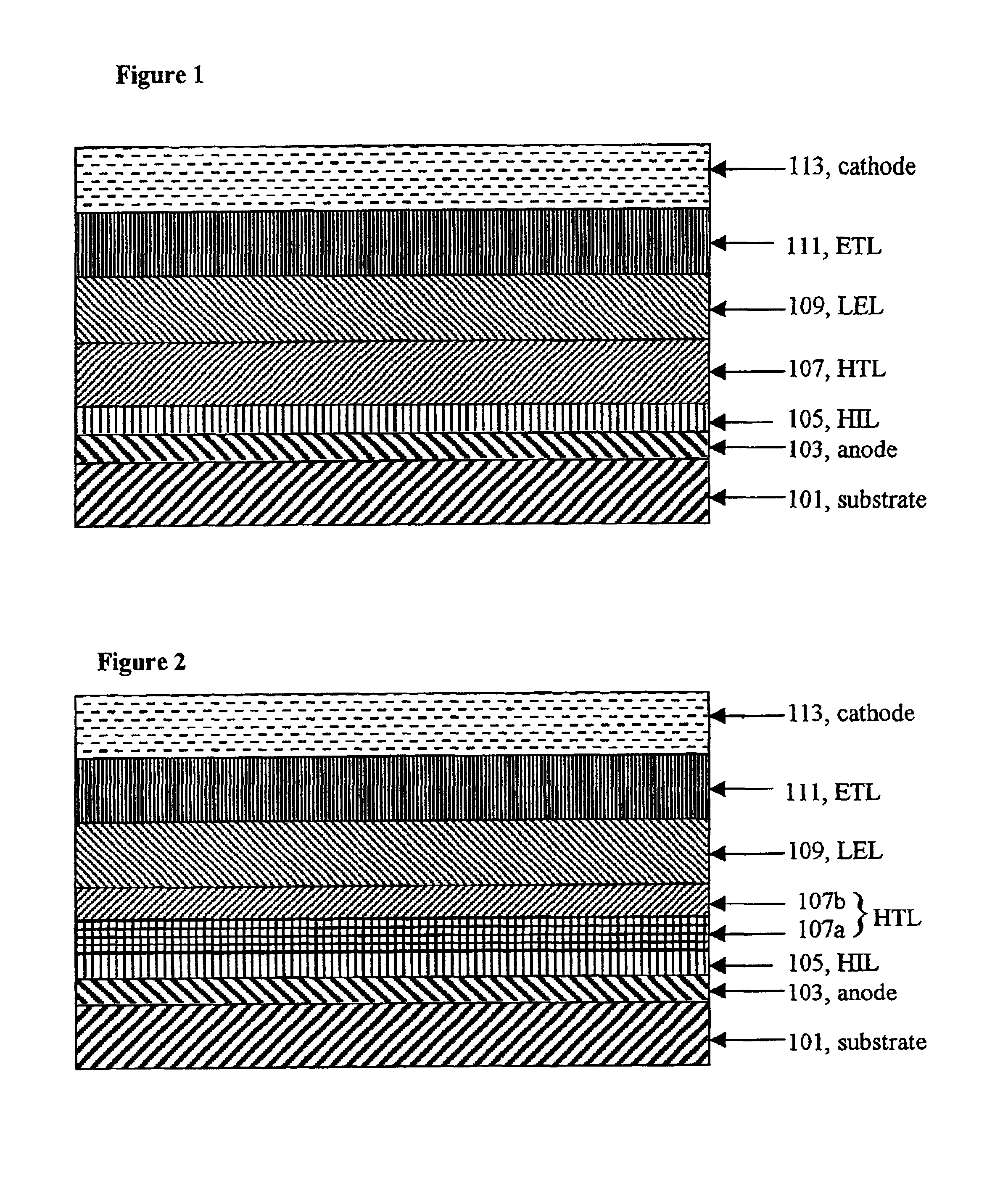

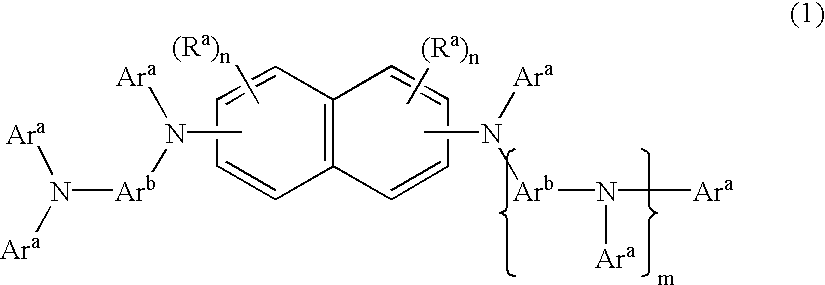

Organic electroluminescent devices with high luminance

InactiveUS6849345B2Organic chemistryDischarge tube luminescnet screensOrganic electroluminescenceHigh luminance

Disclosed is a multilayer electroluminescent device comprising a cathode, an anode, a light emitting layer (LEL) and a layer disposed between the cathode and anode containing a naphthalene compound represented by formula (1): whereinm is 0, 1 or 2;each Ra is an independently selected substituent and each n is independently 0 to 3;each Ara is an independently selected aromatic group; andeach Arb is an independently selected carbocyclic aromatic group;provided that two ring substituents may join to form a ring.The device provides a desired high luminance.

Owner:GLOBAL OLED TECH

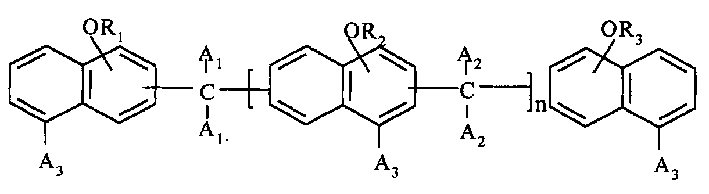

Polyfunctional epoxy resin and its preparation method

A kind of multifunctinoal epoxy resin and its preparation method is involved in this invention. In the formula, A3 is selected from hydrogen atom, cymene, methoxy, bromine atom, R1, R2, R3 are shrink glycerin aethers, the value of n lies between 0 and 8. The preparation process of the method includes: firstly, hydroxy naphthalene compound and bifunctional aldehyde or ketone shrink in the presence of proton acid activator, and multihydroxy naphthalene compound is gained, and then it makes aether reaction with PAE in the action of alkali activator. The epoxy resin has good capability such as high heat-resistance, low moisture absorption and low expandability etc., and fits madding glass cloth or epoxy resin pressing board covering copper and foil, and encapsulation of semiconductor component and IC, so it has capacious application foreground in the electronic industry.

Owner:GUANGZHOU INST OF GEOCHEMISTRY - CHINESE ACAD OF SCI

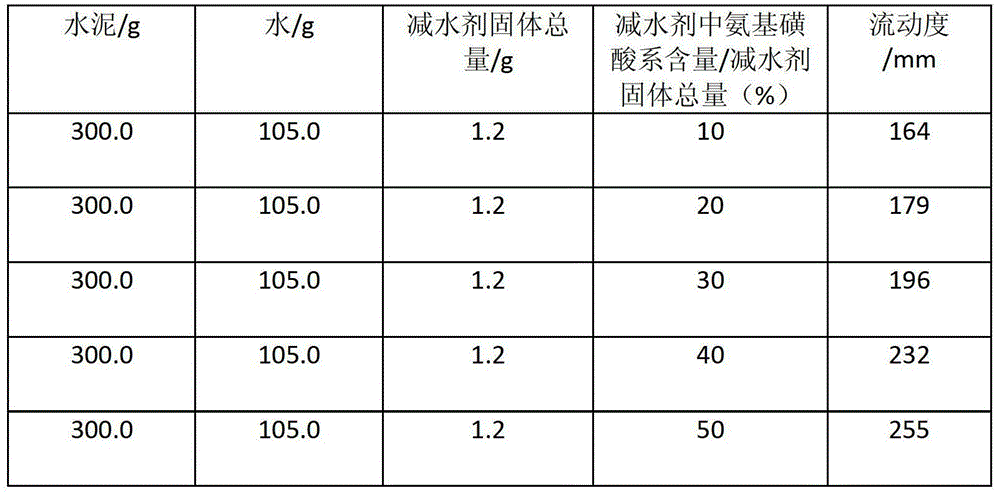

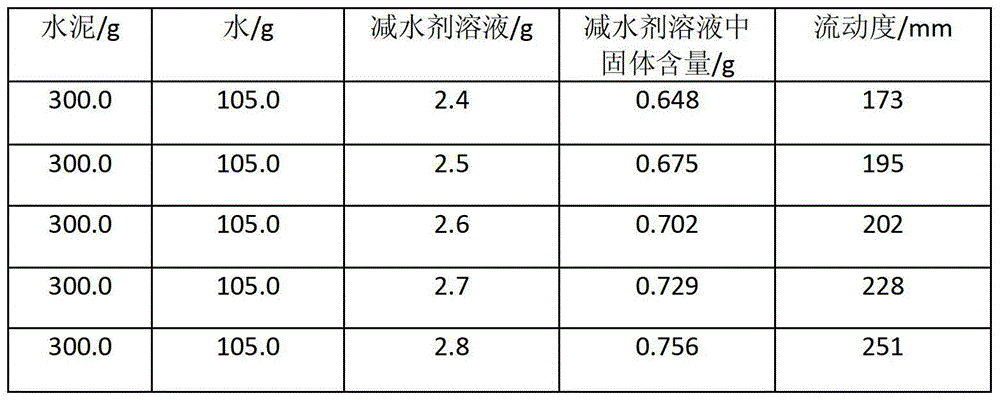

Amino-sulfonic acid and naphthalene compound water reducing agent and preparation method thereof

The invention relates to an amino-sulfonic acid and naphthalene compound water reducing agent and a preparation method thereof. The water reducing agent comprises the following components in percentage by weight: 23 percent to 29 percent of amino-sulfonic acid water reducing agent, 29 percent to 35 percent of naphthalene water reducing agent and 36 percent to 48 percent of water. The preparation method comprises the following steps: heating naphthalene to a molten state; adding concentrated sulfuric acid to sulfonation reaction; then adding water to carry out hydrolysis; adding phenol into sodium hydroxide solution; after uniformly stirring, adding sodium anilinesulfonate to carry out condensation; mixing and stirring two products; and firstly adding formaldehyde, then adding urea and finally adding sodium hydroxide solution to regulate pH to obtain the amino-sulfonic acid and naphthalene compound water reducing agent. The amino-sulfonic acid and naphthalene compound water reducing agent improves performances of high loss speed of the used slump, poor cement adaptability and the like by adding the amino-sulfonic acid water reducing agent into the naphthalene water reducing agent and reaches an effect of improving water reducing rate.

Owner:王中

Multi-substituent-group naphthalene compound with antibacterial activity in aloe as well as preparation method and application of naphthalene compound

ActiveCN107501065AEdible with a long historyEasy to useTobacco treatmentCarbonyl compound separation/purificationChromatographic separationAntibacterial activity

The invention relates to a multi-substituent-group naphthalene compound with antibacterial activity in aloe as well as a preparation method and an application of the naphthalene compound and belongs to the chemical technical field of natural products. The structural formula of the compound is shown in formula (I) in the description. The compound is prepared from traditional edible and medicinal plant aloe as a raw material through extraction, silica gel column chromatography and high-pressure liquid-phase chromatographic separation and purification. Activity tests prove that the compound has a better antibacterial effect and can effectively inhibit growth of microorganisms in a feed liquid and prolong the expiration date of the tobacco feed liquid after being added to the tobacco feed liquid and has good application prospects.

Owner:CHINA TOBACCO YUNNAN IND

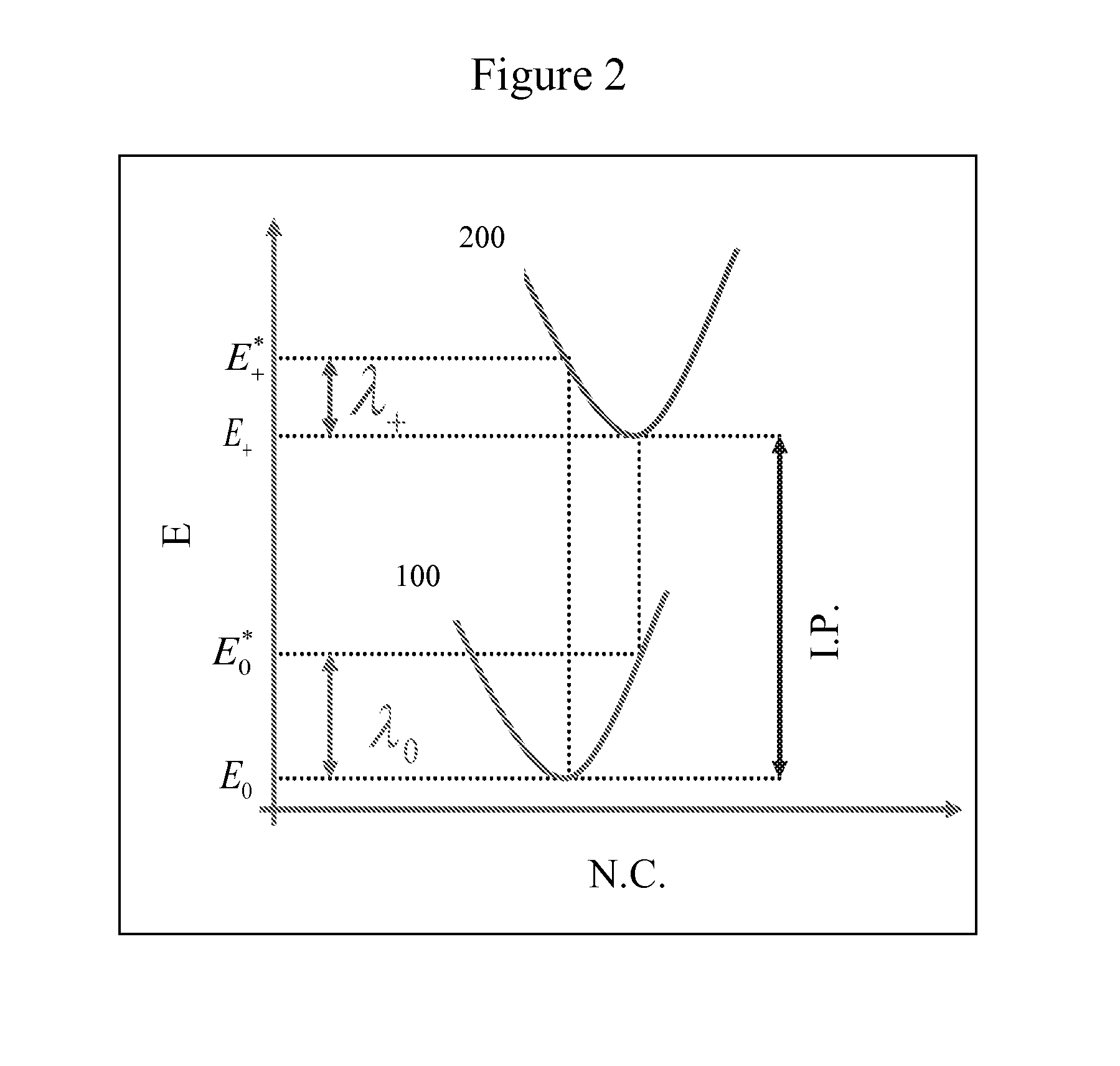

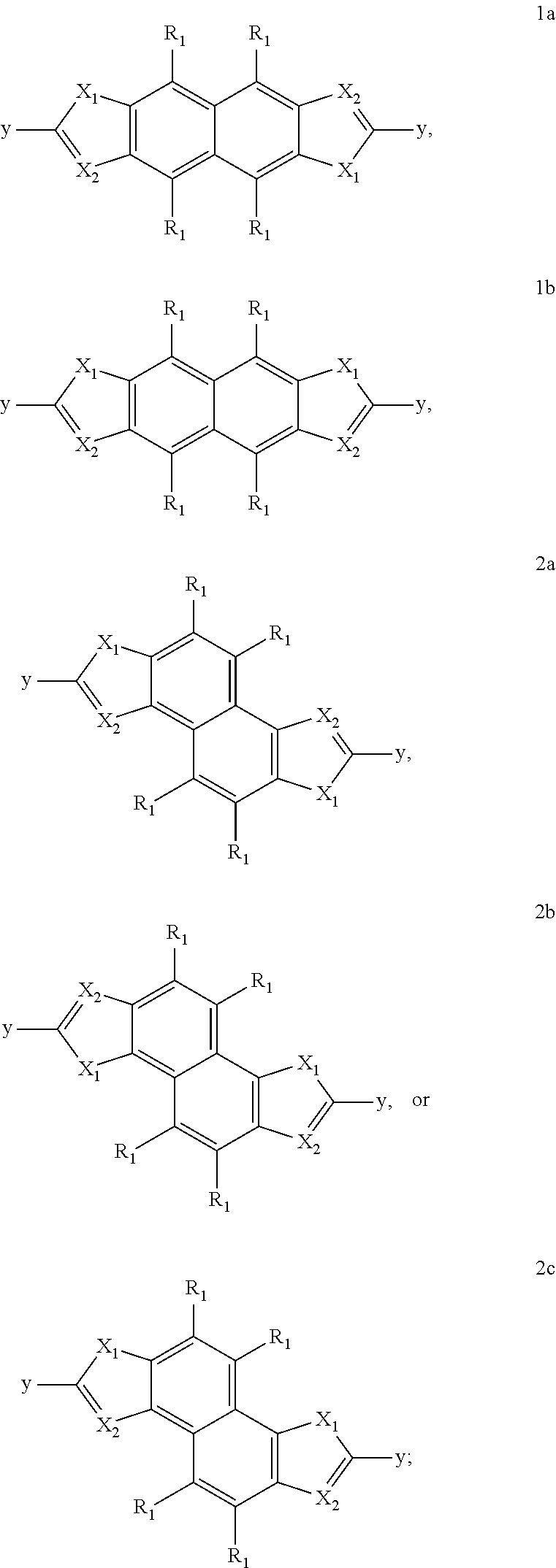

Novel fused naphthalene cyclohetero ring compounds, and methods and uses thereof

InactiveUS20150045560A1Easy to introduceImprove polymerizationSilicon organic compoundsOrganic compound preparationSimple Organic CompoundsOrganic semiconductor

Described herein are heterocyclic organic compounds of following formulae: More specifically, described herein are fused heterocyclic naphthalene compounds, polymers based on fused heterocyclic naphthalene compounds, methods for making these compounds, and uses thereof. The compounds described have improved polymerization and stability properties that allow for improved material processibility for use as organic semiconductors (OSCs).

Owner:CORNING INC

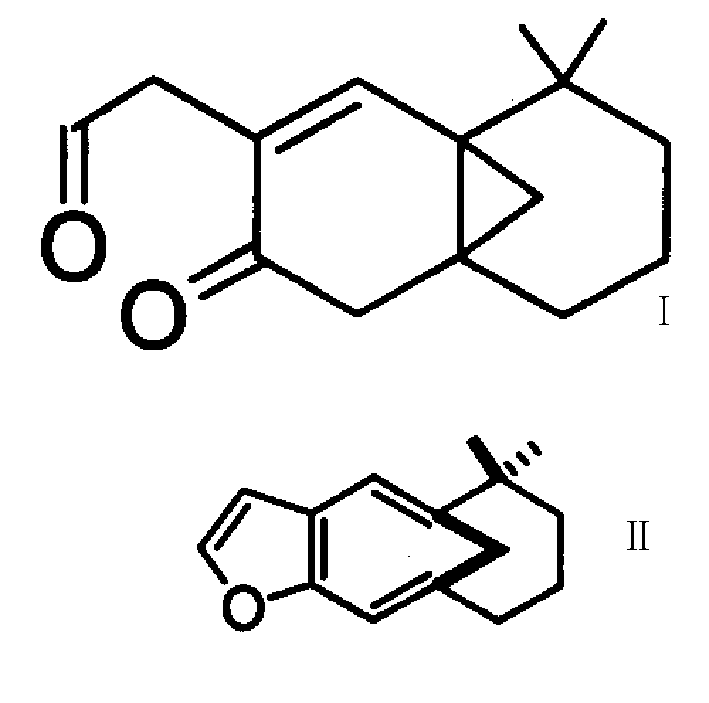

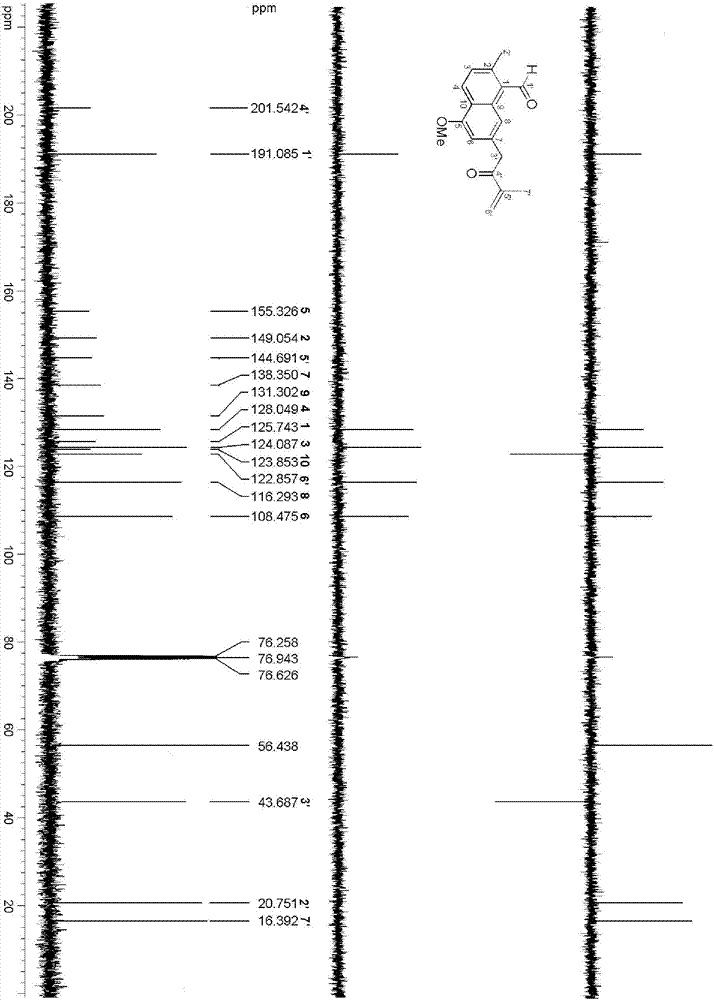

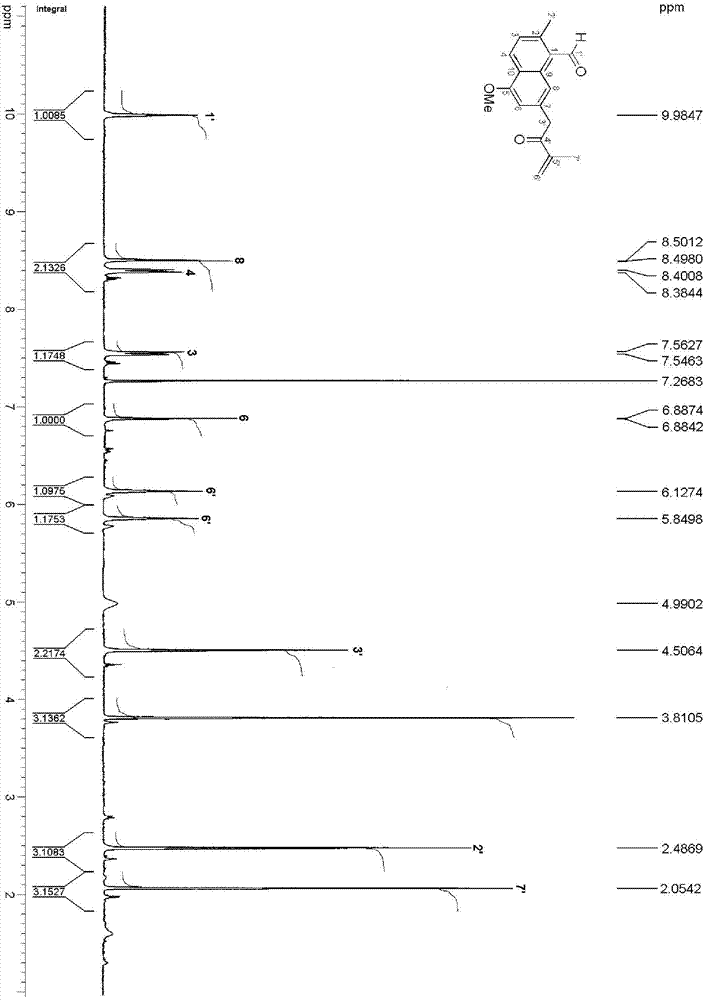

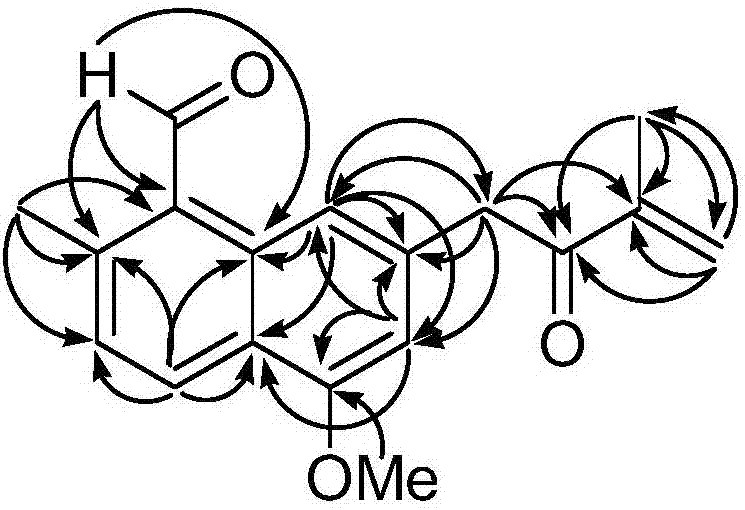

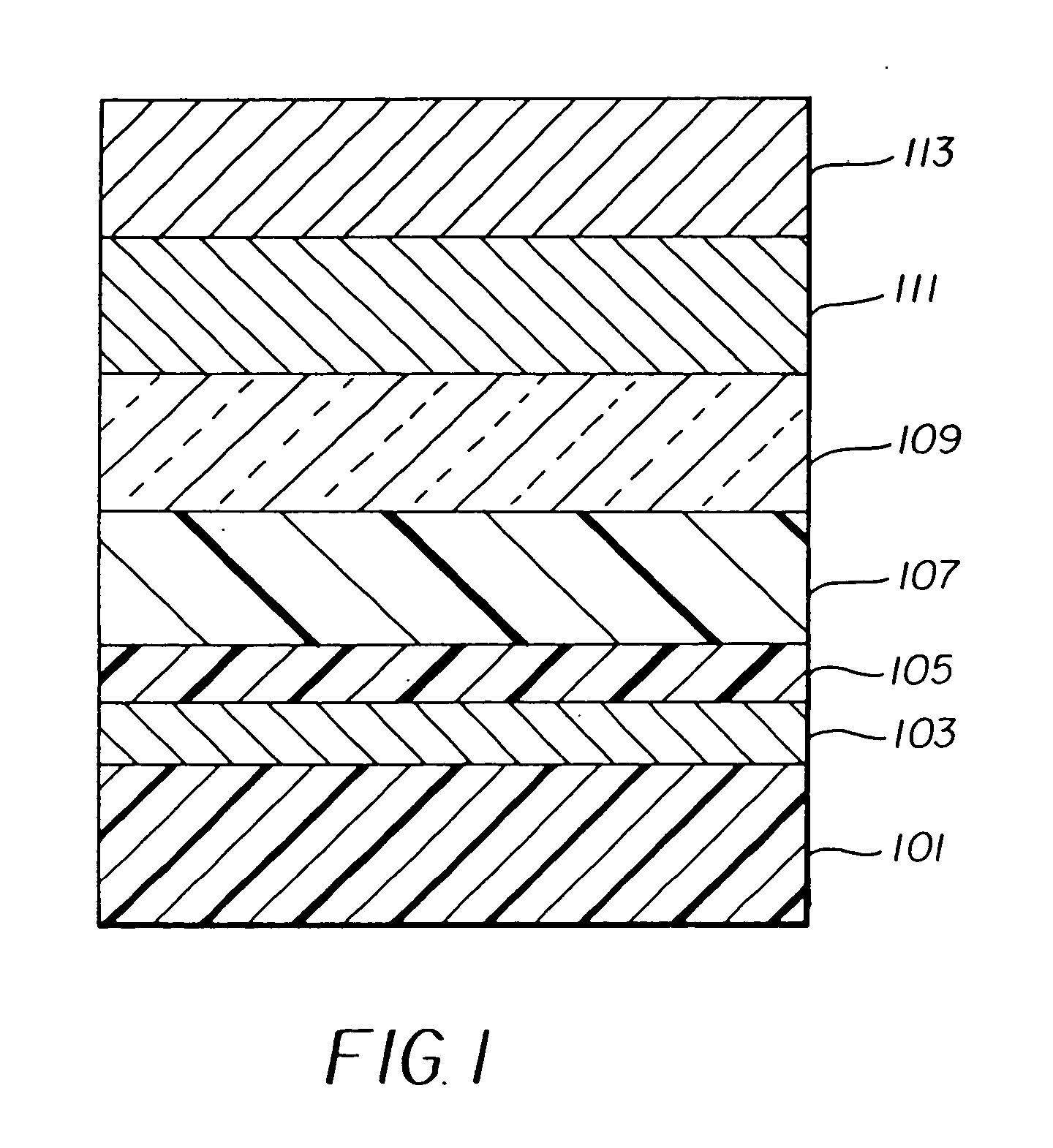

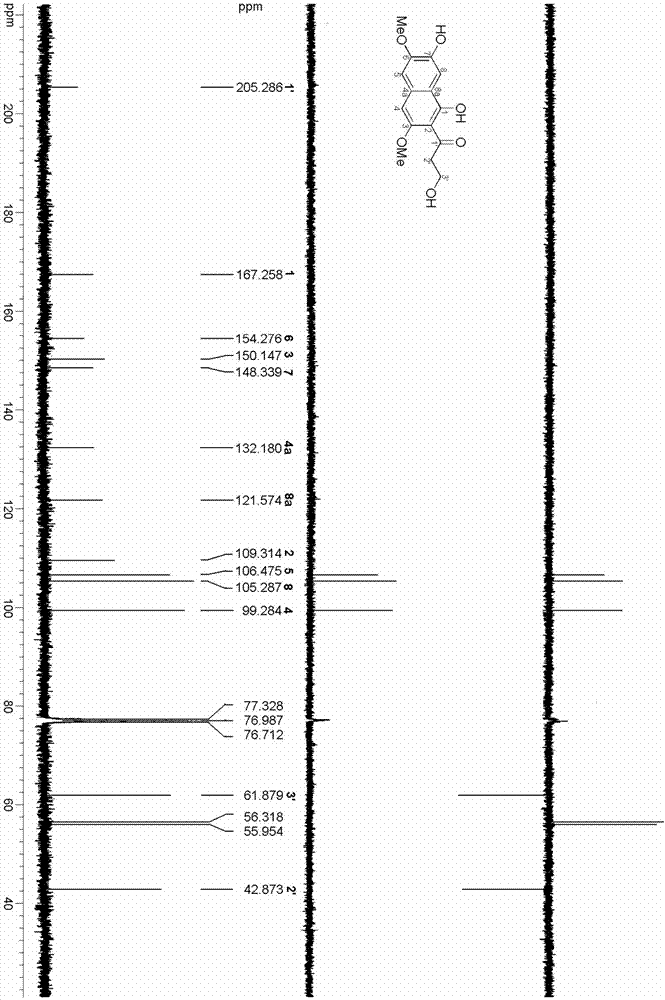

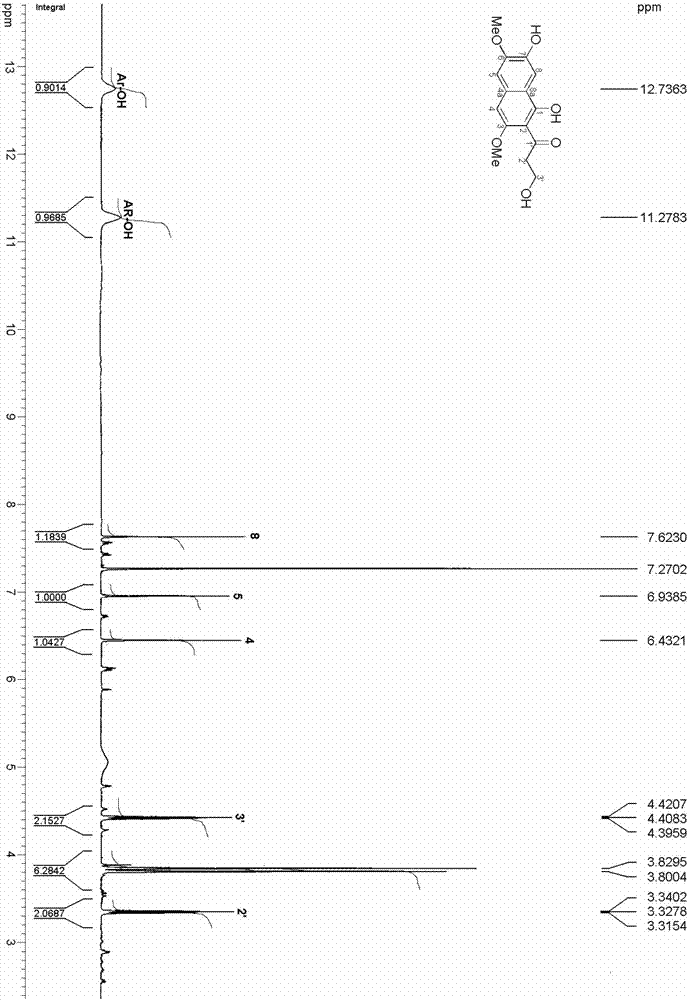

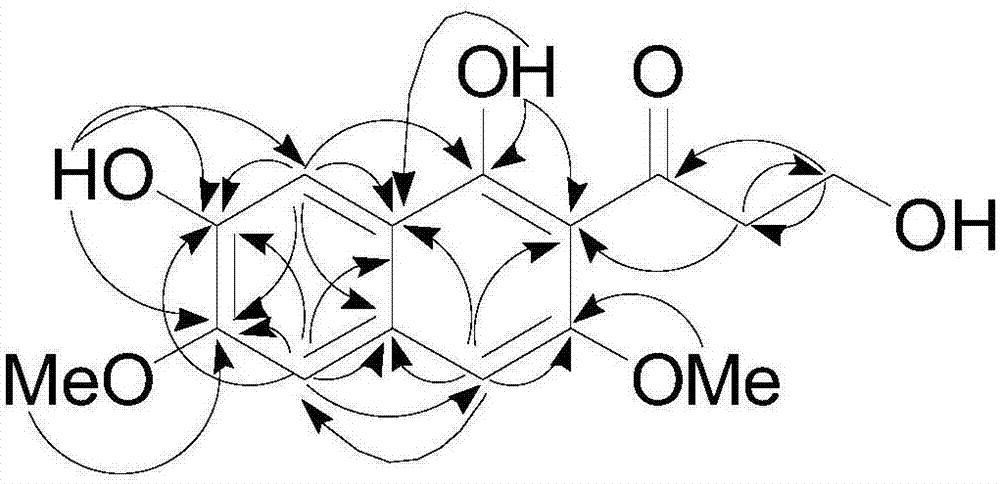

4-bromo-1,2-dihydrocyclobuteneo[alpha]naphthalene compound and preparation method thereof

ActiveCN104447191AHigh purityImprove performanceHalogenated hydrocarbon preparationAcetic acidSodium metabisulfite

The invention discloses a novel method for synthesizing 4-bromo-1,2-dihydrocyclobuteneo[alpha]naphthalene. The method comprises the following steps: (1) adding 1,2-dihydrocyclobuteneo[alpha]naphthalene, glacial acetic acid and methanol into a low-temperature reactor, stirring, and reducing the temperature to be 10 DEG C below zero to 0 DEG C; (2) dissolving bromine in glacial acetic acid at the temperature of 10 DEG C below zero to 0 DEG C, dripping reaction liquid, preserving the temperature after the dripping operation of the reaction liquid is finished, keeping the reaction liquid in dark place, putting the reaction liquid in a low-temperature cabinet freezer, reacting at the temperature of 30 DEG C below zero to 15 DEG C below zero, and standing the reaction liquid at room temperature; (3) adding the reaction liquid into dichloromethane, extracting an organic phase, adding an aqueous solution of sodium metabisulfite into the organic phase, stirring, standing, layering, washing by using deionized water, separating out the organic phase, and drying; and (4) concentrating the dried organic phase into thick solid, and recrystallizing, thereby obtaining 4-bromo-1,2-dihydrocyclobuteneo[alpha]naphthalene. According to the method disclosed by the invention, 1,2-dihydrocyclobuteneo[alpha]naphthalene synthesized by self research and development serves as a raw material, and 4-bromo-1,2-dihydrocyclobuteneo[alpha]naphthalene with excellent performance and low price is synthesized. The reaction conditions are mild, the operation is simple, and the yield is high.

Owner:MIANYANG DAGAOTE NEW MATERIAL

Mesophase pitch material for preparing high-performance carbon fibers and preparation method of mesophase pitch material

InactiveCN104195676AImprove spinnabilityNarrow molecular weight distributionFibre chemical featuresFiberCarbon fibers

The invention relates to a mesophase pitch material for preparing high-performance carbon fibers and a preparation method of the mesophase pitch material. Measured by use of a polarizing microscope, the mesophase content of the mesophase pitch material is 100%; measured by use of a capillary rheometer, the softening point of the mesophase pitch material is 190-270 DEG C and the temperature difference between the flow point and the softening point of the mesophase pitch material is lower than 28 DEG C. The mesophase pitch material is prepared from naphthalene compounds such as methylnaphthalene in the presence of a hydrogen fluoride-boron trifluoride as a catalyst under the control of polymerization conditions and low-boiling point product separation conditions. Compared with the prior art, the mesophase pitch material has the characteristics of excellent spinnability, narrow molecular weight distribution, and good orientation property depending on good melt fluidity, and is advantageous for the control and the operations of a spinning process and also advantageous for preparing the high-performance pitch-based carbon fibers.

Owner:SHANGHAI JIAO TONG UNIV

Intermediate phase asphalt raw material for producing carbon fibers and preparation method thereof

InactiveCN104151531AExcellent pre-oxidation performanceFast oxidation reactionFibre chemical featuresFiberCarbon fibers

The present invention relates to an intermediate phase asphalt raw material for producing carbon fibers and a preparation method thereof, wherein the intermediate phase asphalt raw material intermediate phase content determined through the polarizing microscope method is 100%, S1 / S2 in the infrared absorption spectrogram of the intermediate phase asphalt is more than 1.7, S1 is the area of the absorption peak at the wavelength of 2800-2990 cm<-1>, S2 is the area of the absorption peak at the wavelength of 2990-3150 cm<-1>, S3 / S4 in the <13>C nuclear magnetic resonance spectrogram of the intermediate phase asphalt is less than 19, S3 is the area of the absorption peak with the chemical shift of 23.8-58.0 ppm, and S4 is the area of the absorption peak with the chemical shift of 8.0-23.8 ppm. According to the present invention, methylnaphthalene and other naphthalene compounds are adopted as raw materials, hydrogen fluoride-boron trifluoride is adopted as a catalyst, and the polymerization conditions are controlled to prepare the intermediate phase asphalt. Compared with the intermediate phase asphalt in the prior art, the intermediate phase asphalt of the present invention has characteristics of excellent spinnability, excellent pre-oxidation property and simple preparation process control, and can be adopted as the industrial production raw material of the high strength and high modulus asphalt-base carbon fibers.

Owner:SHANGHAI JIAO TONG UNIV

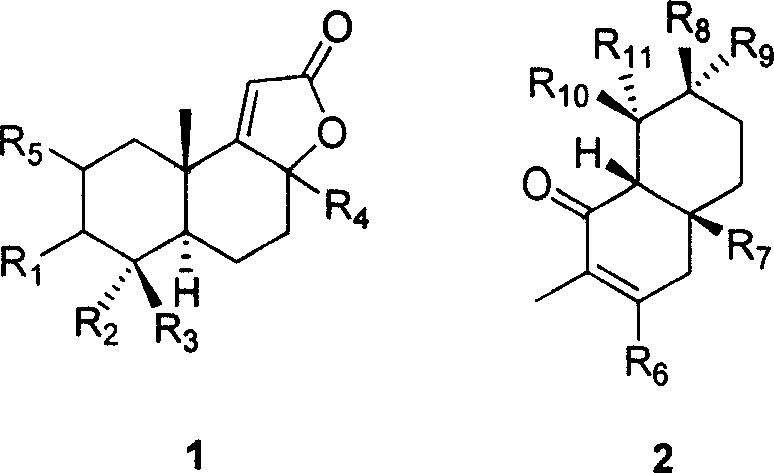

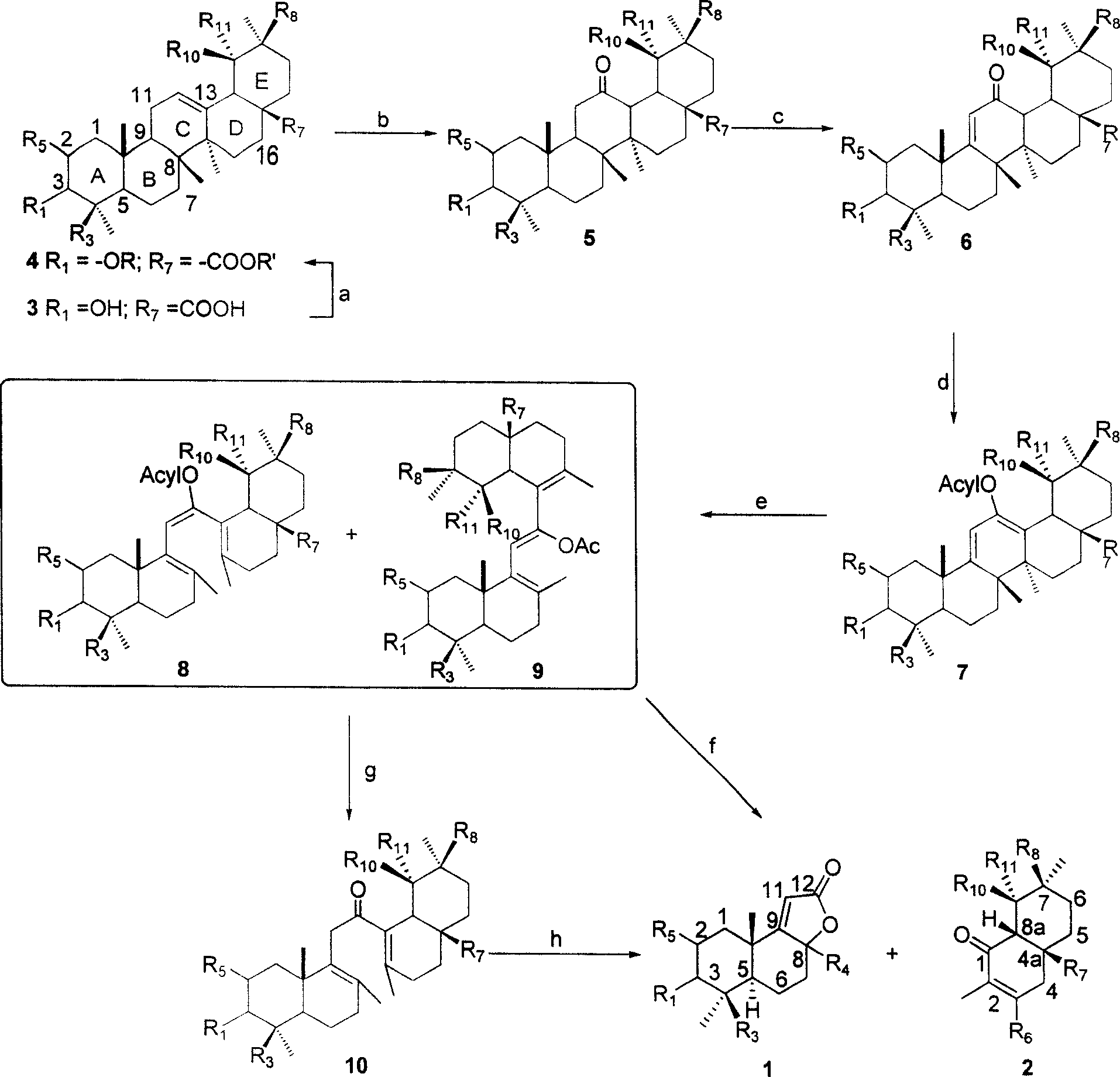

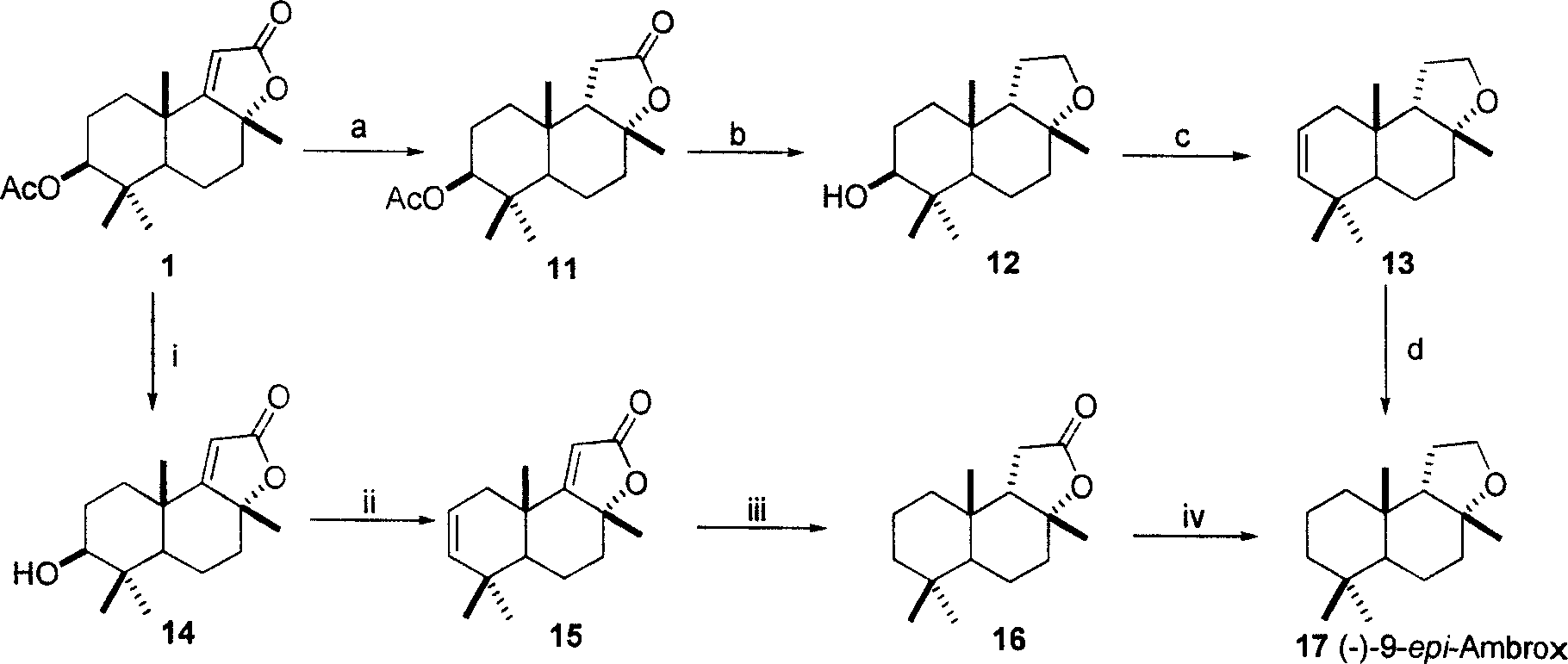

Polysubstitution hydrogenated naphthalene compounds, producing method and uses of the same

The present invention belongs to the field of organic chemistry and relates to a multi-substituted hydrogenated naphthalene compound, the preparation methods and uses. Specifically, the present invention relates to a chiral multi-substituted ten-hydrogen and / or eight-hydrogen naphthalene compound, the synthetic method and uses. The present invention aims to provide a chiral multi-substituted ten-hydrogen and / or eight-hydrogen naphthalene compound; the oleanane-type or usu-type five-ring triterpenoid compound is used as a raw material for preparing the compound. The multi-substituted ten-hydrogen and / or eight-hydrogen naphthalene compound of the present invention can be used for synthesis of drugs or spices containing multi-hydrogen naphthalene fragments and the analogues. The method of the present invention is simple and easy, low in cost, high in production rate, and can realize industrialization.

Owner:CHENGDU INST OF BIOLOGY CHINESE ACAD OF S

3-substituted 5,6,7,8 tetrahydro-4a,8a method-2-keto-naphthalene, synthesis method and use thereof

InactiveCN1405136AEfficient synthesisEasy to getOrganic compound preparationPreparation by hydrogenolysisHydrogenNatural product

The invention relates to a kind of 3 substituted 5,6,7,8 tetrahydro-41, 8a methylene-2-ketonaphthalene compound, synthesis method and its application. Said invention provides its structural formula, it is simple, suitable for industrial production, and can be used for synthesizing dihydrogen derivative dihydrospiniferin-1 of marine natural product spiniferin-1.

Owner:SHANGHAI INST OF ORGANIC CHEM CHINESE ACAD OF SCI

Naphthalene compound extracted from lavender, and preparation method and application thereof

ActiveCN107162891AStrong antibacterial activitySimple structureTobacco treatmentCarbonyl compound separation/purificationEscherichia coliChromatographic separation

The invention discloses a naphthalene compound extracted from lavender, and a preparation method and application thereof. The compound is named 5-methoxy-2-methyl-7-(3-methyl-2-oxobut-3-enyl)-1-naphthaldehyde. The preparation method comprises the following steps: carrying out organic solvent extraction on a raw material perfume plant lavender to obtain an extract, carrying out silica gel column chromatography, and carrying out high pressure liquid chromatography separation and purification. The compound is nontoxic for animals and safe to use, and has favorable antibacterial activities, and the antibacterial rates for Escherichia coli, Staphylococcus aureus and the like respectively reach 93.4% or above. When being applied to preservation of tobacco sauce, the compound can effectively inhibit growth of microbes in the liquid and prolong the preservation period of the tobacco sauce.

Owner:CHINA TOBACCO YUNNAN IND

Production technology of dispersing agent MF (melamine-formaldehyde resin)

InactiveCN103360285ANothing producedLow costSulfonic acids salts preparationSulfonic acid preparationEnvironmental engineeringSulfur trioxide

The invention discloses a production technology of dispersing agent MF (melamine-formaldehyde resin). The production technology is carried out by the following steps: leading sulfur trioxide to naphthalene materials to carry out sulfonation reaction; adding formaldehyde water solution to carry out condensation reaction; adding liquid caustic soda to adjust pH to a neutral state; filtering to obtain dispersing agent MF water solution; drying to obtain solid powder dispersing agent MF. The production technology is simple in procedure, and convenient to operate; compared with the traditional technology, sulfuric acid does not need to be added to a naphthalene compound while sulfur trioxide is directly led to carry out sulfonation. Thus, the material cost is saved; meanwhile, the process is simplified; environmental pollution and a potential safety hazard caused by treatment of concentrated sulfuric acid are avoided; no solid waste residue is generated.

Owner:安阳市双环助剂有限责任公司

Method for recovering solvents

A method for recovering a solvent from its mixture containing oligomers extracted from grafted polyolefins is disclosed. The method comprises distilling the solvent from the mixture in the presence of a naphthalene compound. The method of the invention significantly increases the solvent recovering yield without causing the vessel fouling.

Owner:LYONDELL CHEM TECH LP

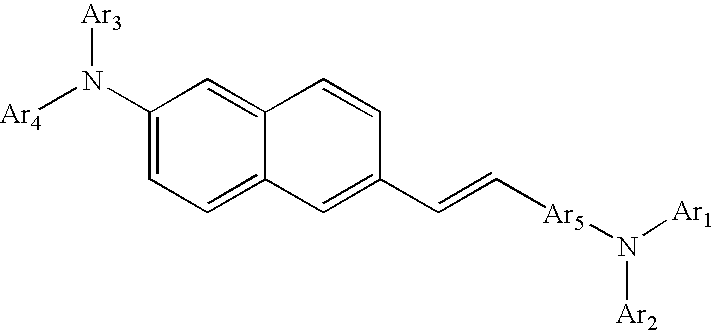

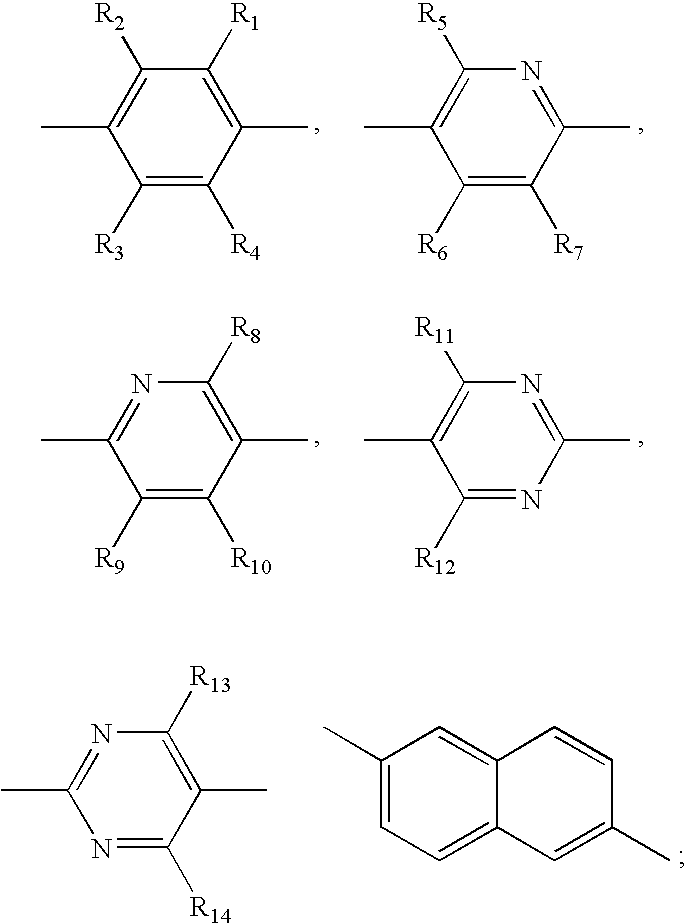

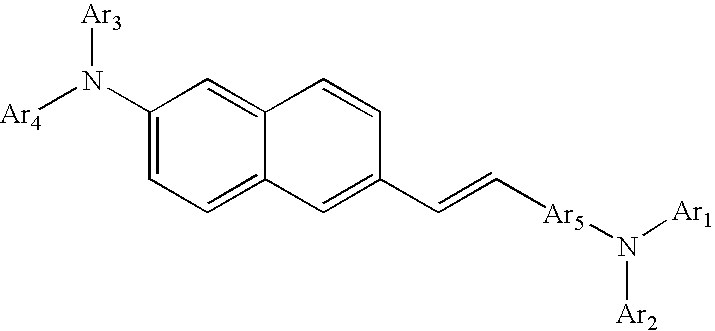

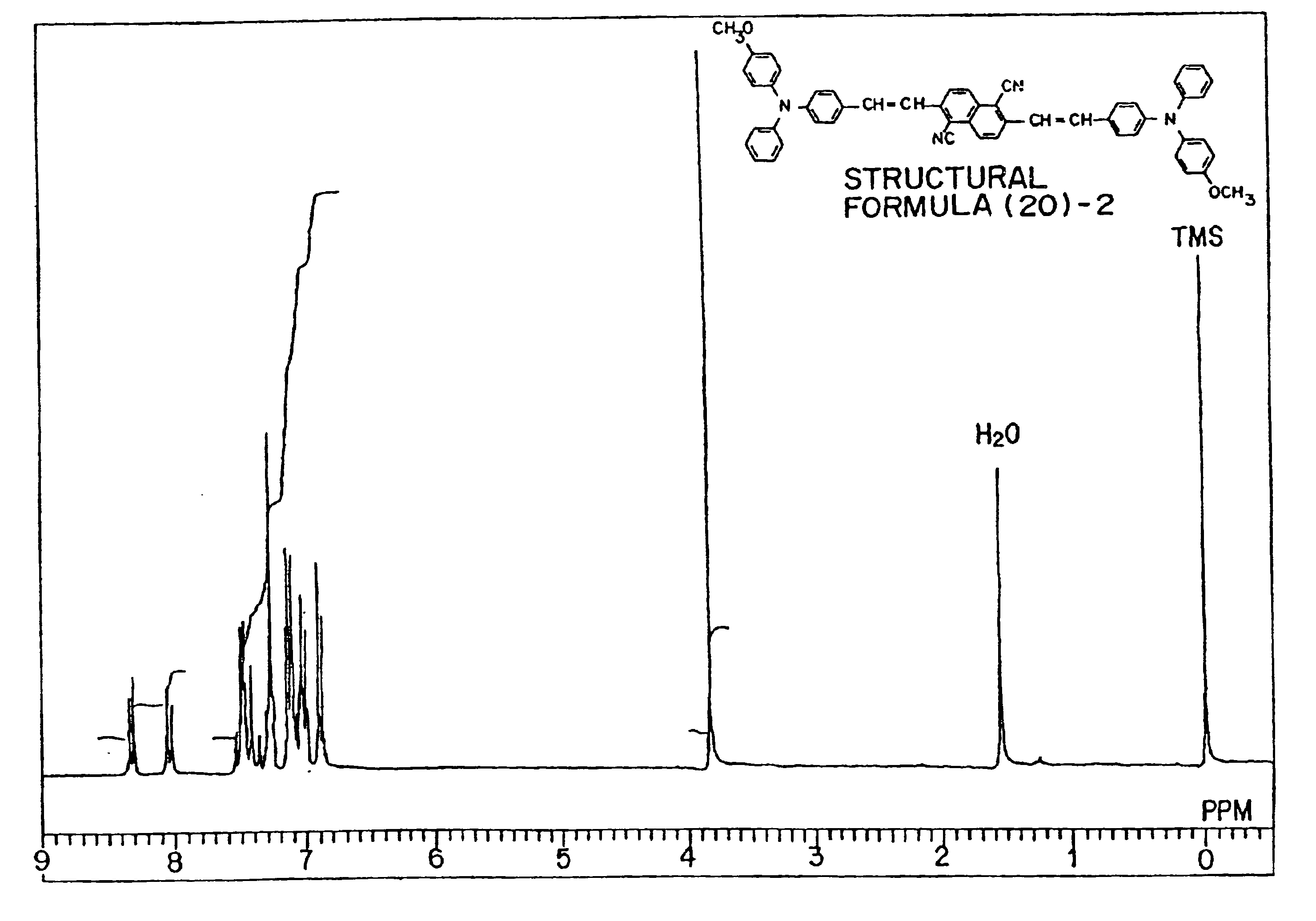

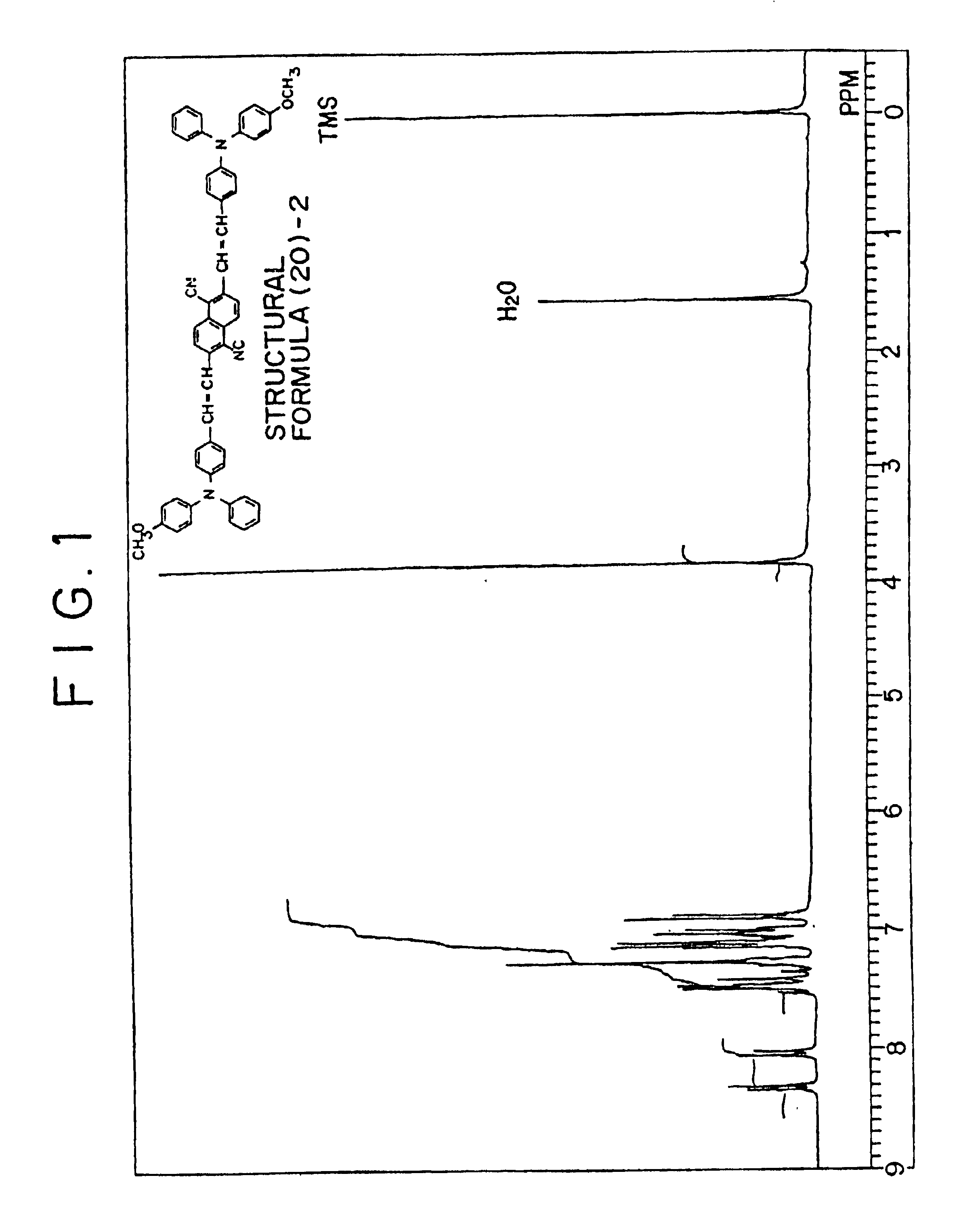

Diarylamino substituted arylvinyl naphthalene compounds and a blue-light electroluminescent device having the compounds

InactiveUS20060159953A1Improve luminous efficiencyImprove efficiencyOrganic chemistryDischarge tube luminescnet screensArylIsopropyl

Diarylamino arylvinyl naphthalene compounds, particularly used in blue-light organic light-emitting diodes with highly pure color, have the following representative formula: wherein Ar1, Ar2, Ar3 and Ar4 are identical or different substituents selected from the group consisting of phenyl, biphenyl, 1-naphthyl, 2-naphthyl, fluorophenyl, fluorobiphenyl, 1-fluoronaphthyl, 2-fluoronaphthyl, phenyl substituted by methyl or ethyl or isopropyl or tert-butyl or methoxy or ethoxy_, 1-naphthyl substituted by methyl or ethyl or isopropyl or tert-butyl or methoxy or ethoxy, 2-naphthyl substituted by methyl or ethyl, fluorophenyl substituted by methyl or isopropyl or tert-butyl or methoxy or ethoxy; wherein “Ar5” is one of the following substitutive groups consisting of: wherein the R1 to R14 are identical or different and are hydrogen,

Owner:LABELTECK

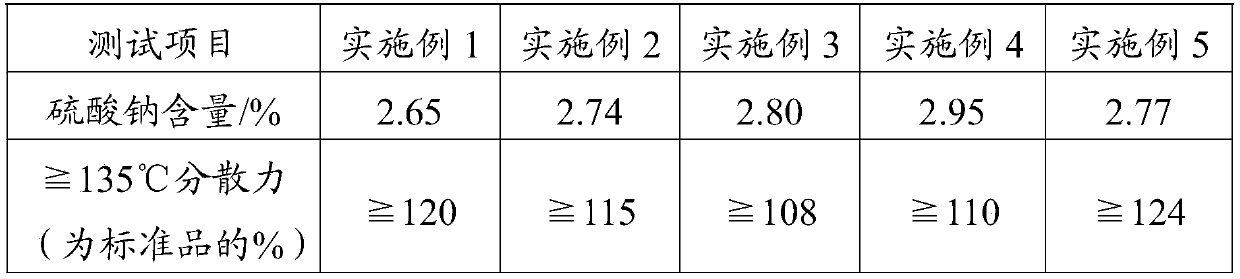

Novel method for preparing naphthalene sodium sulfonate formaldehyde condensation compound through continuous flows

ActiveCN109096153AWell mixedFacilitated DiffusionSulfonic acids salts preparationSulfonic acid preparationContinuous flowSodium sulfate

The invention discloses a novel method for preparing a naphthalene sodium sulfonate formaldehyde condensation compound through continuous flows. The method comprises the following steps: putting a naphthalene compound into a stirring kettle A at a kettle temperature of 40-90 DEG C; putting concentrated sulfuric acid into a stirring kettle B; injecting into an internal spiral tube type reactor at the same time, and controlling the temperature to 140-150 DEG C to carry out a reaction so as to obtain a sulfonation liquid; putting the sulfonation liquid into a stirring kettle C, adjusting the acidity to 15-20%, putting a formaldehyde solution into a stirring kettle D, injecting into the internal spiral tube type reactor at the same time, and controlling the temperature to 105-120 DEG C to carry out a reaction so as to obtain a condensation liquid; putting the condensation liquid into a stirring kettle E, and keeping the temperature at 100 DEG C; putting a sodium hydroxide solution into a stirring kettle F, and injecting into the internal spiral tube type reactor at the same time, and controlling the temperature to 70-90 DEG C to carry out a reaction so as to obtain a neutralization product; drying the neutralization product, and evaporating off moisture, thereby obtaining a brown-yellow solid product. The novel method is safe, simple and efficient in process, and the synthesized naphthalene sodium sulfonate formaldehyde condensation compound is low in content of sodium sulfate, and good in thermal resistance stability.

Owner:江苏精禾界面科技有限公司

105% acid sulfonation manufacturing technique of 2-naphthalenol

The present invention relates to a 105 percent acidic sulfonation production process of 2-naphthol, and belongs to the technical field of chemical production. In the process, molten refined naphthalene is added into a reaction still and is heated to be at the temperature between 135 DEG C and 140 DEG C, sulfuric acid of 105 percent is added within 30 minutes according to a mass ratio of 1.28 to 1, the temperature in the reaction still is raised to be 160 DEG C and maintained for 135 minutes, the sulphonation product with an acidity of 24 to 27 percent is prepared, and the next procedure is performed. The present invention solves the problems in the traditional process with sulphonation of sulphuric acid of 100 percent that water is generated in the process of substituting hydrogen on a double benzene nucleus with sulfonic group and has dilution effects on sulphuric acid, the substitution reaction is impeded, water becomes water vapor at the temperature of 160 DEG C which has hydrolysis effects on 1-naphthalene sulfonic acid and 2-naphthalene sulfonic acid, and the total yield rate of the sulfonation reaction is not high. And the present invention has the advantages that sulfuric acid of 105 percent is added, the sulfonation conversion and the product yield rate are improved, the generated naphthalene compounds and other byproducts are reduced, and the yield rate is improved by 1.1 percent.

Owner:湖北鑫慧化工有限公司

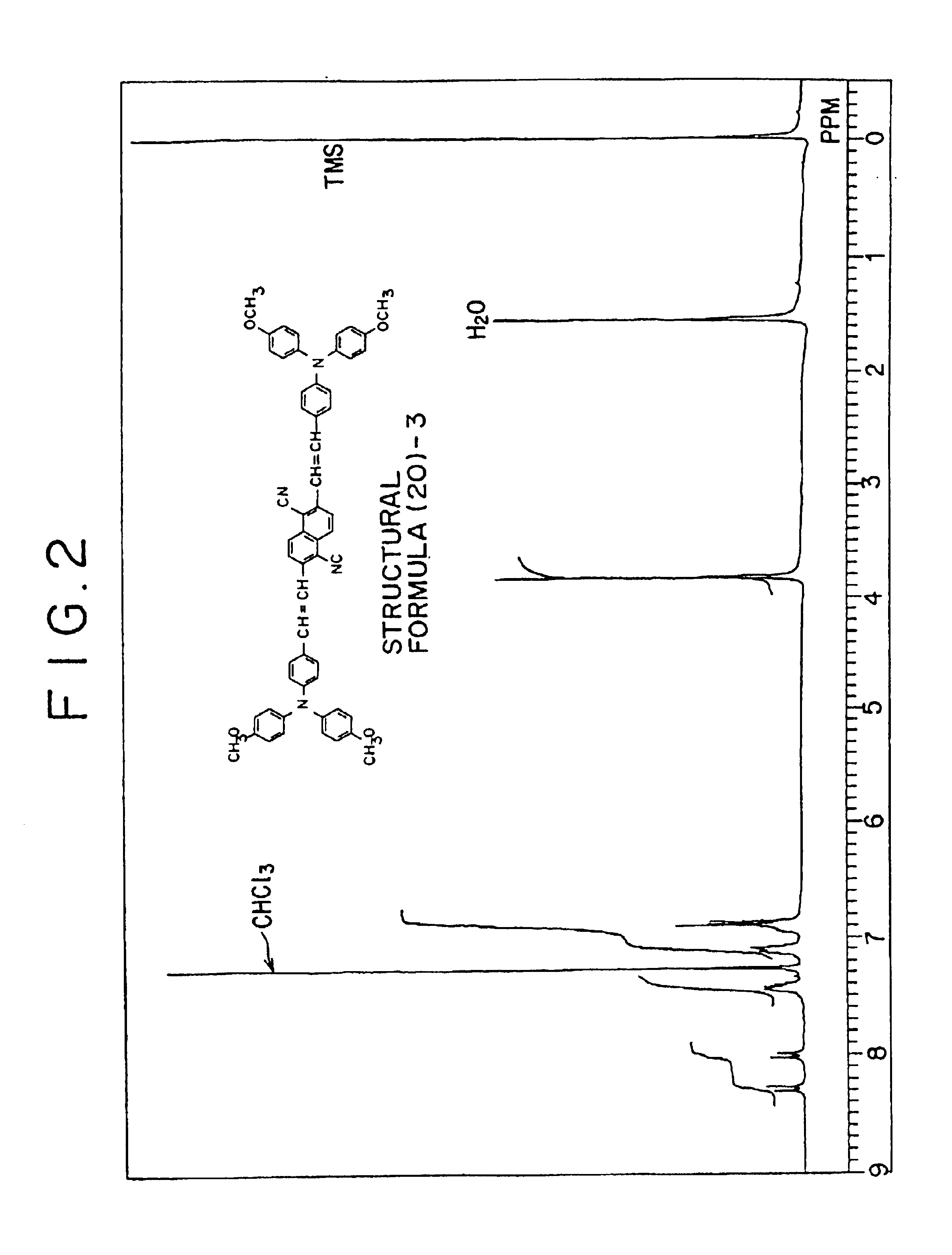

Bis(aminostyryl)naphthalene compound, synthesis intermediate thereof, and process for production thereof

A bis(aminostyryl)naphthalene compound represented by the general formula [I] or the like below. (where R2 and R3 each denotes an unsubstituted aryl group; R1 and R4 each denotes an aryl group having a specific substituent such as methoxy group; and R5 and R6 each denotes a cyano group or the like.)A process for producing a bis(aminostyryl)naphthalene compound represented by the general formula [I] by condensation of, for example, 4-(N,N-diarylamino)benzaldehyde with diphosphonic ester or diphosphonium.The bis(aminostyryl)naphthalene compound emits intense yellow or red light. The process permits efficient production of the bis(aminostyryl)naphthalene compound.

Owner:JOLED INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

![4-bromo-1,2-dihydrocyclobuteneo[alpha]naphthalene compound and preparation method thereof 4-bromo-1,2-dihydrocyclobuteneo[alpha]naphthalene compound and preparation method thereof](https://images-eureka.patsnap.com/patent_img/0018a48a-6f88-4a1e-8940-67b5dd801eb9/HDA0000598110610000011.PNG)

![4-bromo-1,2-dihydrocyclobuteneo[alpha]naphthalene compound and preparation method thereof 4-bromo-1,2-dihydrocyclobuteneo[alpha]naphthalene compound and preparation method thereof](https://images-eureka.patsnap.com/patent_img/0018a48a-6f88-4a1e-8940-67b5dd801eb9/HDA0000598110610000012.PNG)

![4-bromo-1,2-dihydrocyclobuteneo[alpha]naphthalene compound and preparation method thereof 4-bromo-1,2-dihydrocyclobuteneo[alpha]naphthalene compound and preparation method thereof](https://images-eureka.patsnap.com/patent_img/0018a48a-6f88-4a1e-8940-67b5dd801eb9/BDA0000598110600000011.PNG)