Method for increasing yield of xylene through lightening of heavy aromatic hydrocarbons

A technology for heavy aromatics and xylene, which is applied in chemical instruments and methods, bulk chemical production, organic chemistry, etc., can solve the problem of inability to effectively treat heavy aromatics components containing naphthalenes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

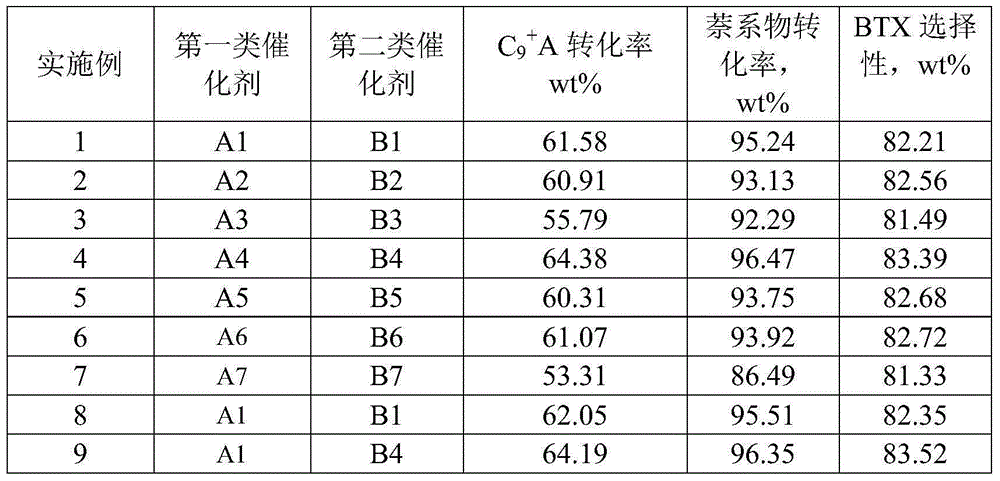

Examples

Embodiment 1

[0015] Add 60 grams of pseudo-boehmite to a certain amount of dilute nitric acid and Tianqing powder, knead evenly, extrude into strips, roast to make a carrier, and place it in an impregnation container after dicing. A certain amount of chloroplatinic acid and nickel nitrate were dissolved in water, impregnated on the surface of the carrier, dried at 120°C for 4 hours, and calcined at 500°C for 3 hours to prepare catalyst A1.

[0016] 70 g Na 2 Beta molecular sieve with O content less than 0.5% (weight) is mixed with 55 grams of pseudoboehmite and an appropriate amount of Tianqing powder, then a certain amount of dilute nitric acid is added to extrude, dried, and roasted to make a carrier, which is placed after pelletizing in an immersion container. Catalyst B1 was obtained by dissolving a certain amount of chloroplatinic acid and stannous chloride in water, co-impregnating the surface of the carrier, drying at 120°C for 4 hours, and calcining at 500°C for 3 hours.

[0017]...

Embodiment 2

[0019] Add 60 grams of kaolin to a certain amount of dilute nitric acid and Tianqing powder, knead evenly, extrude into strips, roast to make a carrier, and place it in an impregnation container after dicing. A certain amount of chloroplatinic acid and nickel nitrate was dissolved in water, impregnated on the surface of the carrier, dried at 120°C for 4 hours, and calcined at 500°C for 3 hours to prepare catalyst A2.

[0020] 70 g Na 2 O content is less than 0.5% (weight) MOR molecular sieve and 55 grams of pseudo-boehmite and an appropriate amount of Tianqing powder are evenly mixed, then a certain amount of dilute nitric acid is added, extruded, dried, and roasted to make a carrier, after pelletizing Place in a soaking container. Catalyst B2 was obtained by dissolving a certain amount of chloroplatinic acid and stannous chloride in water, co-impregnating the surface of the carrier, drying at 120°C for 4 hours, and calcining at 500°C for 3 hours.

[0021] Mix 10 grams of ca...

Embodiment 3

[0023] A certain amount of silica sol is added to 60 grams of magnesia, extruded and roasted to make a carrier, and placed in an impregnation container after being cut into pellets. A certain amount of chloroplatinic acid and nickel nitrate was dissolved in water, impregnated on the surface of the carrier, dried at 120°C for 4 hours, and calcined at 500°C for 3 hours to prepare catalyst A3.

[0024] 50 g Na 2 O content is less than 0.5% (weight) MOR molecular sieve, 20 grams of Na 2 O content is less than 0.5% (weight) ZSM-5 molecular sieve and 55 grams of pseudo-boehmite and an appropriate amount of Tianqing powder are mixed evenly, then add a certain amount of dilute nitric acid, extrude, dry, roast to make carrier, cut Place the pellets in the soaking container. Catalyst B3 was obtained by dissolving a certain amount of chloroplatinic acid and stannous chloride in water, co-impregnating the surface of the carrier, drying at 120°C for 4 hours, and calcining at 500°C for 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com