Sulfonating technique for producing dye dispersant MF (melamine-formaldehyde)

A dye dispersant and production process technology, which is applied in the preparation of sulfonic acid, organic chemistry, sulfonate preparation, etc., to achieve the effects of simple production process, short sanding time, and avoiding calcium sulfate residue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

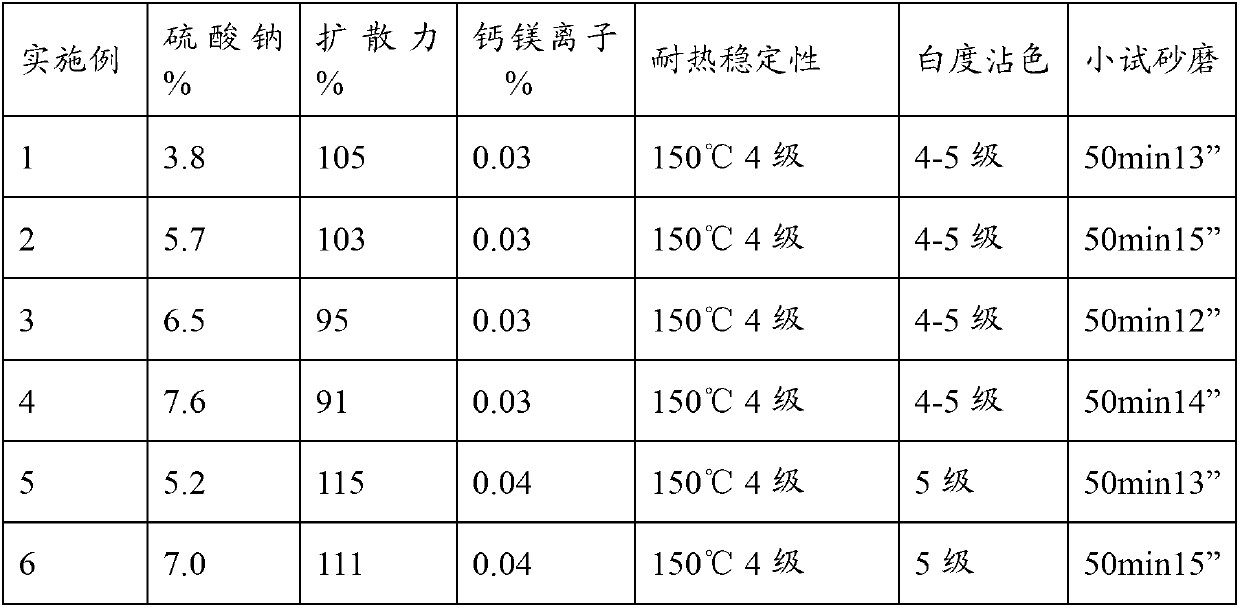

Examples

Embodiment 1

[0025] Weigh 100 grams of industrial methylnaphthalene and put it into a 500ml four-necked flask with a stirrer and a thermometer, start stirring, heat up to 50°C, add 17.6 grams of 98% sulfuric acid dropwise, and then slowly introduce 47.9 grams of sulfur trioxide. The temperature does not exceed 80°C. After the addition, keep the reaction for 1 hour, then raise the temperature to 150°C, turn on the vacuum 0.05-0.06MPa, keep the reaction for 3 hours, check the acid value to 25%, cool to 120°C, add water to the acid value After the concentration is 21%, cool to 80°C, add 45 grams of 37% formaldehyde solution dropwise, control the temperature not to exceed 100°C, after the addition, heat up to 100-110°C for condensation reaction for 4 hours. Then add 30% liquid caustic soda for neutralization. The neutralizing material was dried, and the obtained amount was 190 grams.

Embodiment 2

[0027] Weigh 100 grams of industrial methylnaphthalene and put it into a 500ml four-neck flask with a stirrer and a thermometer, start stirring, heat up to 50°C, add 24.6 grams of 98% sulfuric acid dropwise, and then slowly introduce 53.5 grams of sulfur trioxide. The temperature does not exceed 80°C. After the addition, keep the reaction for 1 hour, then raise the temperature to 150°C, turn on the vacuum of 0.05-0.06MPa, keep the reaction for 3 hours, check the acid value of 28%, cool to 120°C, add water to a certain acidity After the value is 21%, cool to 80°C, add 45 grams of 37% formaldehyde solution dropwise, control the temperature not to exceed 100°C, after the addition, heat up to 100-110°C for condensation reaction for 4 hours. Then add 30% liquid caustic soda for neutralization. The neutralizing material was dried, and the obtained amount was 199 grams.

Embodiment 3

[0029] Weigh 100 grams of industrial washing oil and put it into a 500ml four-neck flask equipped with a stirrer and a thermometer, start stirring, raise the temperature to 50°C, add 17.6 grams of 98% sulfuric acid dropwise, and then slowly introduce 47.9 grams of sulfur trioxide. No more than 80°C. After the addition, keep the reaction for 1 hour, then raise the temperature to 140°C, turn on the vacuum of 0.05-0.06MPa, keep the reaction for 3 hours, check the acid value of 26%, cool to 120°C, add water to a certain acid value After 21%, cool to 80°C, add 45 grams of 37% formaldehyde solution dropwise, control the temperature not to exceed 100°C, after the addition, heat up to 100-110°C for condensation reaction for 4 hours. Then add 30% liquid caustic soda for neutralization. The neutralized material was dried, and the obtained amount was 185 grams.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com