Novel method for preparing naphthalene sodium sulfonate formaldehyde condensation compound through continuous flows

A technology of sodium naphthalene sulfonate and formaldehyde condensate, which is applied in the preparation of sulfonic acid, sulfonate, organic chemistry, etc. Solve the problems of high temperature and viscosity, reduce the amount of concentrated sulfuric acid, and have the effect of uniform and rapid reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

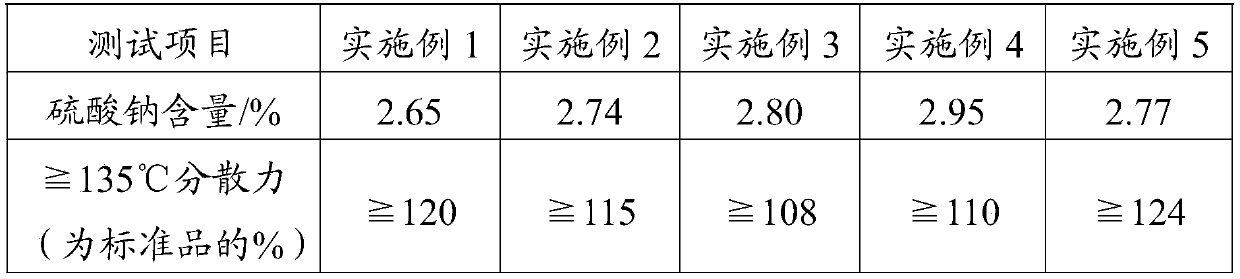

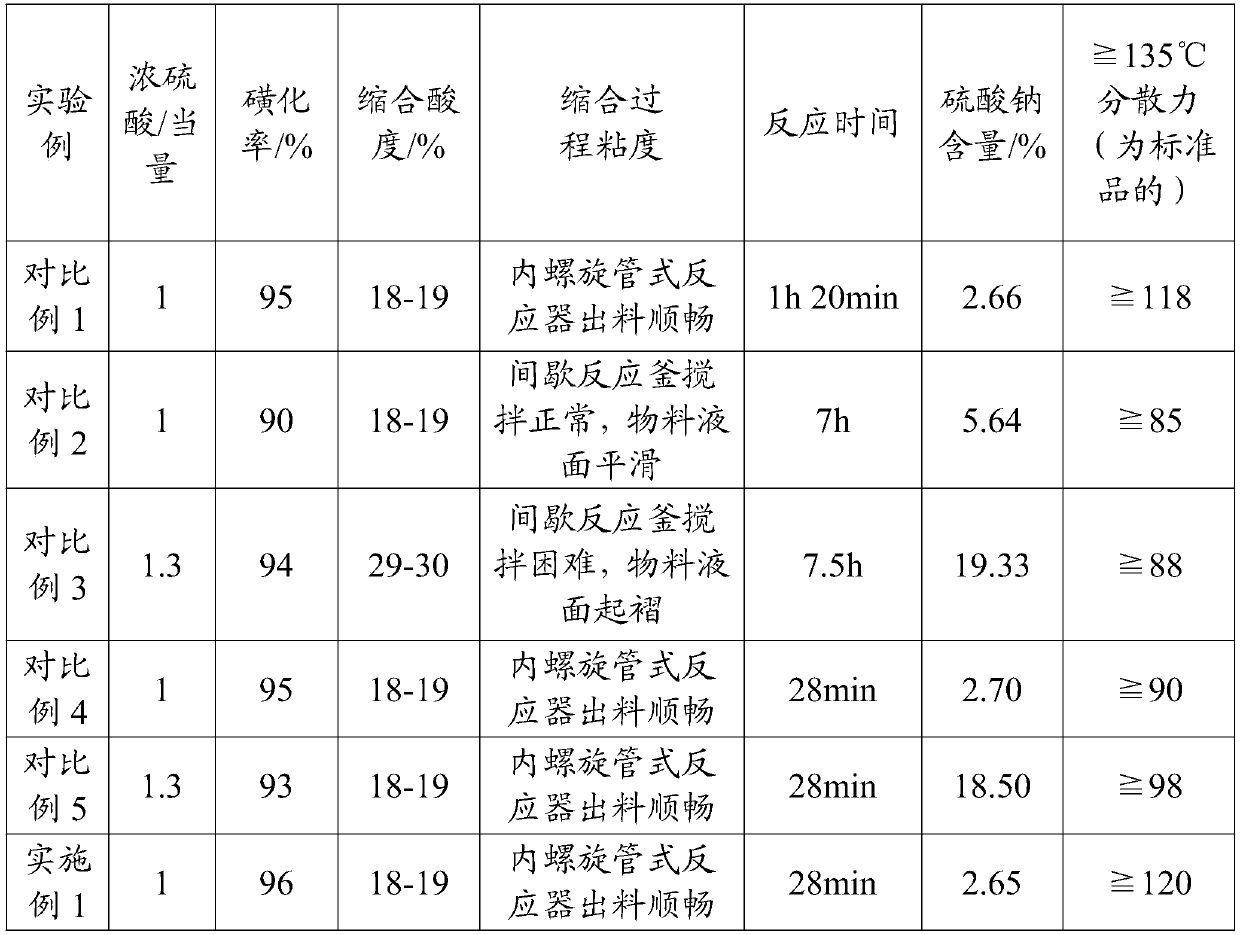

Examples

Embodiment 1

[0035] A kind of new method that continuous flow prepares naphthalene series sodium sulfonate formaldehyde condensate, the steps are as follows:

[0036] 1) Sulfonation: Add 64g refined naphthalene in stirred tank A and heat up to 85°C for melting, add 50g concentrated sulfuric acid (98%) in stirred tank B, set the temperature of the inner helical tubular reactor at 150°C, and use a push injection pump to Molten naphthalene was injected at a speed of 2mL / min and concentrated sulfuric acid at a speed of 1mL / min into an inner helical tubular reactor for reaction to synthesize a sulfonated liquid, which was collected in a stirred tank C with a temperature of 100°C, and the discharge rate was controlled to be 3mL / min. min, the sulfonated liquid stays in the reactor for 8 min.

[0037] 2) Condensation: Add an appropriate amount of water to the sulfonated solution to adjust the acidity to 18-19%, and at the same time add 32g of 37% formaldehyde solution to the stirred tank D, adjust...

Embodiment 2

[0042] A kind of new method that continuous flow prepares naphthalene series sodium sulfonate formaldehyde condensate, the steps are as follows:

[0043]1) Sulfonation: Add 64g of industrial naphthalene in stirred tank A and heat up to 85°C for melting, add 51g of concentrated sulfuric acid (98%) in stirred tank B, set the temperature of the inner helical tubular reactor at 145°C, and use a push injection pump to Molten naphthalene was injected into the internal helical tubular reactor at a speed of 1.8mL / min, and concentrated sulfuric acid was injected into an inner helical tubular reactor at a speed of 0.8mL / min to react and synthesize sulfonated liquid, which was collected in a stirred tank C with a temperature of 100°C, and the discharge speed was controlled to 2.6mL / min, the sulfonated liquid stays in the reactor for 10min.

[0044] 2) Condensation: Add an appropriate amount of water to the sulfonated solution to adjust the acidity to 19-20%, and at the same time add 30g ...

Embodiment 3

[0049] A kind of new method that continuous flow prepares naphthalene series sodium sulfonate formaldehyde condensate, the steps are as follows:

[0050] 1) Sulfonation: Add 71g of methylnaphthalene to the stirred tank A and heat up to 40°C to melt, add 52g of concentrated sulfuric acid (98%) to the stirred tank B, set the temperature of the inner helical tubular reactor at 148°C, and use a push injection pump Push molten naphthalene at a speed of 2.2mL / min and concentrated sulfuric acid at a speed of 1.1mL / min into an inner helical tubular reactor for reaction to synthesize a sulfonated liquid, which is collected in a stirred tank C with a temperature of 100°C, and the discharge speed is controlled 3.3mL / min, make the sulfonated liquid stay in the reactor for 7min.

[0051] 2) Condensation: Add an appropriate amount of water to the sulfonated solution to adjust the acidity to 18-19%. At the same time, add 28g of 37% formaldehyde solution into the stirred tank D, adjust the te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com