Production technology of dispersing agent MF (melamine-formaldehyde resin)

A production process and dispersant technology, applied in the field of dispersant MF production process, can solve the problems of complicated process and high cost of raw materials, and achieve the effect of simplified process, simple process and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

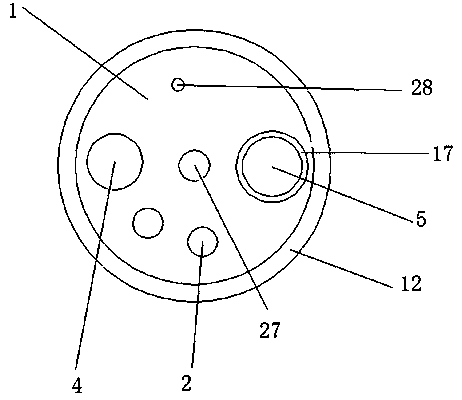

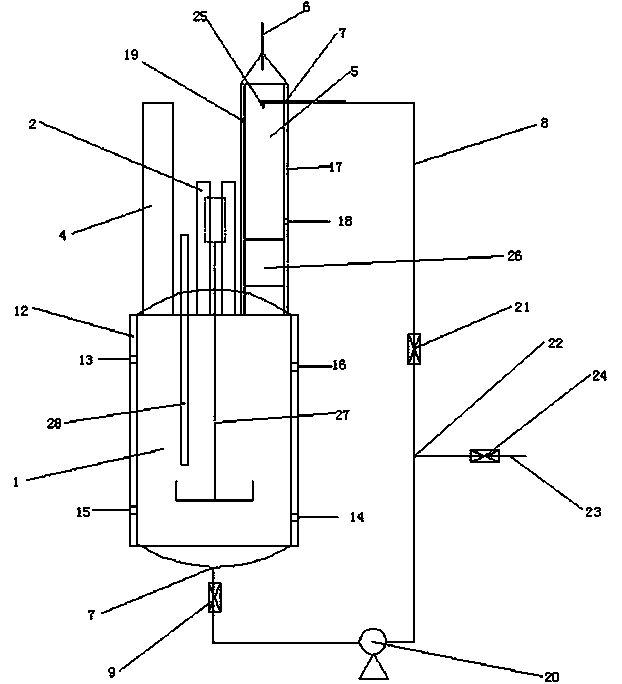

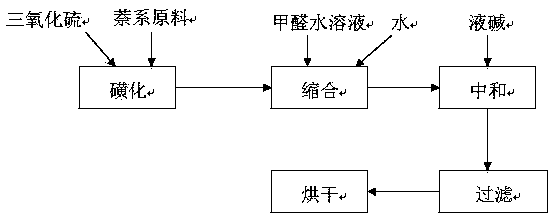

Method used

Image

Examples

Embodiment 1

[0032] 1) Sulfonation: Put 70g of industrial washing oil into the sulfonation reactor, then slowly pass in 35g of sulfur trioxide gas with a volume concentration of 4%, control the reaction temperature at 110-115°C through the above-mentioned sulfonation reactor, and pass The injection time is about 2 hours. After the ventilation is over, keep warm for 1 hour and then raise the temperature to 130°C. Continue to react at this temperature for 3-4 hours, and then take a sample to test the acidity of the solution. After the acidity is qualified, cool down to 110°C. Can;

[0033] 2) Condensation: After the temperature drops to 75°C, add 35g of formaldehyde aqueous solution, raise the temperature to 115°C, react for 5-6 hours, dilute with water and pass into the neutralization reaction tank;

[0034] 3) Neutralization: pass in liquid caustic soda (32% sodium hydroxide solution) to adjust the pH to neutral, and pass through the filter;

[0035] 4) Filtration and drying: After filter...

Embodiment 2

[0037] 1) Sulfonation: put 70g of industrial washing oil into the sulfonation reactor, then slowly pass in 35g of sulfur trioxide gas with a volume concentration of 7%, control the reaction temperature at 110-115°C through the above-mentioned sulfonation reactor, and pass The injection time is about 2 hours. After the ventilation is over, keep warm for 1 hour and then raise the temperature to 130°C. Continue to react at this temperature for 3-4 hours, and then take a sample to test the acidity of the solution. After the acidity is qualified, cool down to 110°C. tank, the material entrained in the tail gas of the sulfonation reactor is condensed into a liquid through the graphite cooler and returned to the sulfonator;

[0038] 2) Condensation: After the temperature drops to 75°C, add 35g of formaldehyde aqueous solution, raise the temperature to 115°C, react for 5-6 hours, dilute with water and pass into the neutralization reaction tank;

[0039] 3) Neutralization: pass in liqu...

Embodiment 3

[0043] 1) Sulfonation: Put 70g of methylnaphthalene into the sulfonation reactor, and then slowly feed 35g of sulfur trioxide gas with a volume concentration of 9%, and control the reaction temperature to 110-115°C through the above-mentioned sulfonation reactor, and pass The injection time is about 2 hours. After the ventilation is over, keep warm for 1 hour and then raise the temperature to 130°C. Continue to react at this temperature for 3-4 hours, and then take a sample to test the acidity of the solution. After the acidity is qualified, cool down to 110°C. tank, the material entrained in the tail gas of the sulfonation reactor is condensed into a liquid through the graphite cooler and returned to the sulfonator;

[0044] 2) Condensation: After the temperature drops to 75°C, add 35g of formaldehyde aqueous solution, raise the temperature to 115°C, react for 5-6 hours, dilute with water and pass into the neutralization reaction tank;

[0045] 3) Neutralization: pass in liquid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com