Novel computerized flat knitting mechanism

A computerized flat knitting machine, a new type of technology, applied to flat knitting machines with individual moving needles, knitting, weft knitting, etc., can solve the problems of high production precision, difficulty in mass promotion, complex structure, etc., and achieve the goal of knitting mechanism And control mechanism simplification, small size, size reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

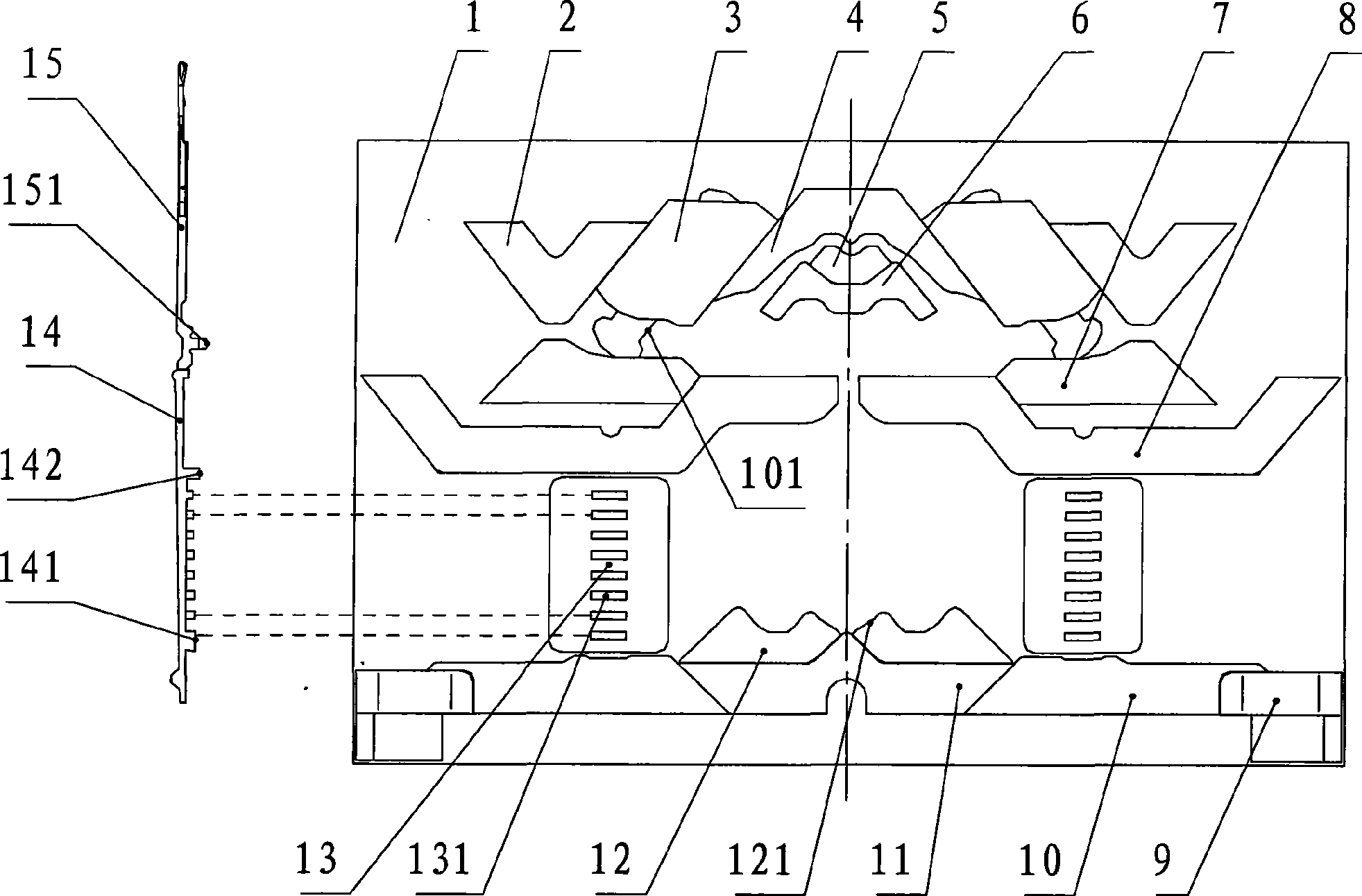

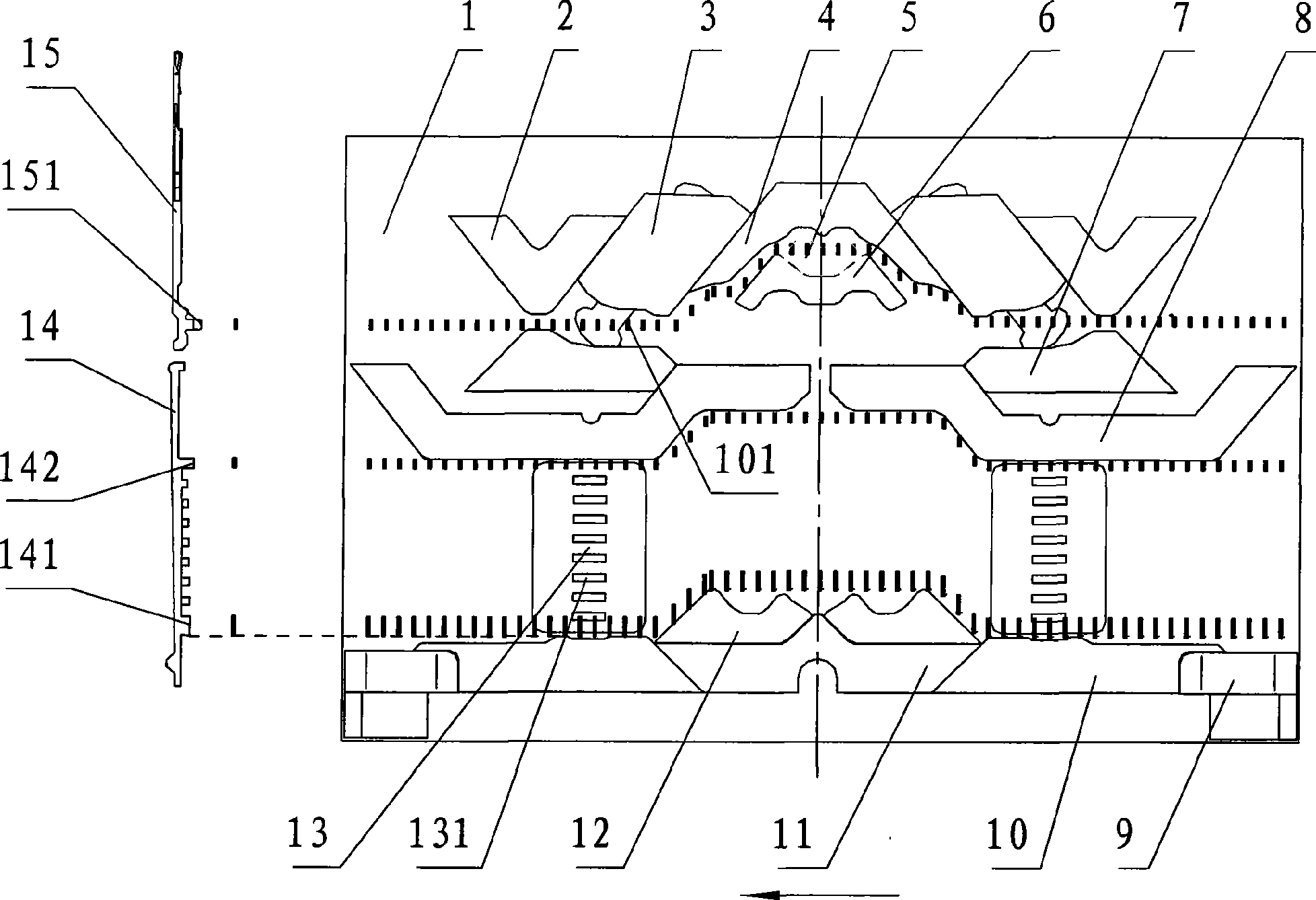

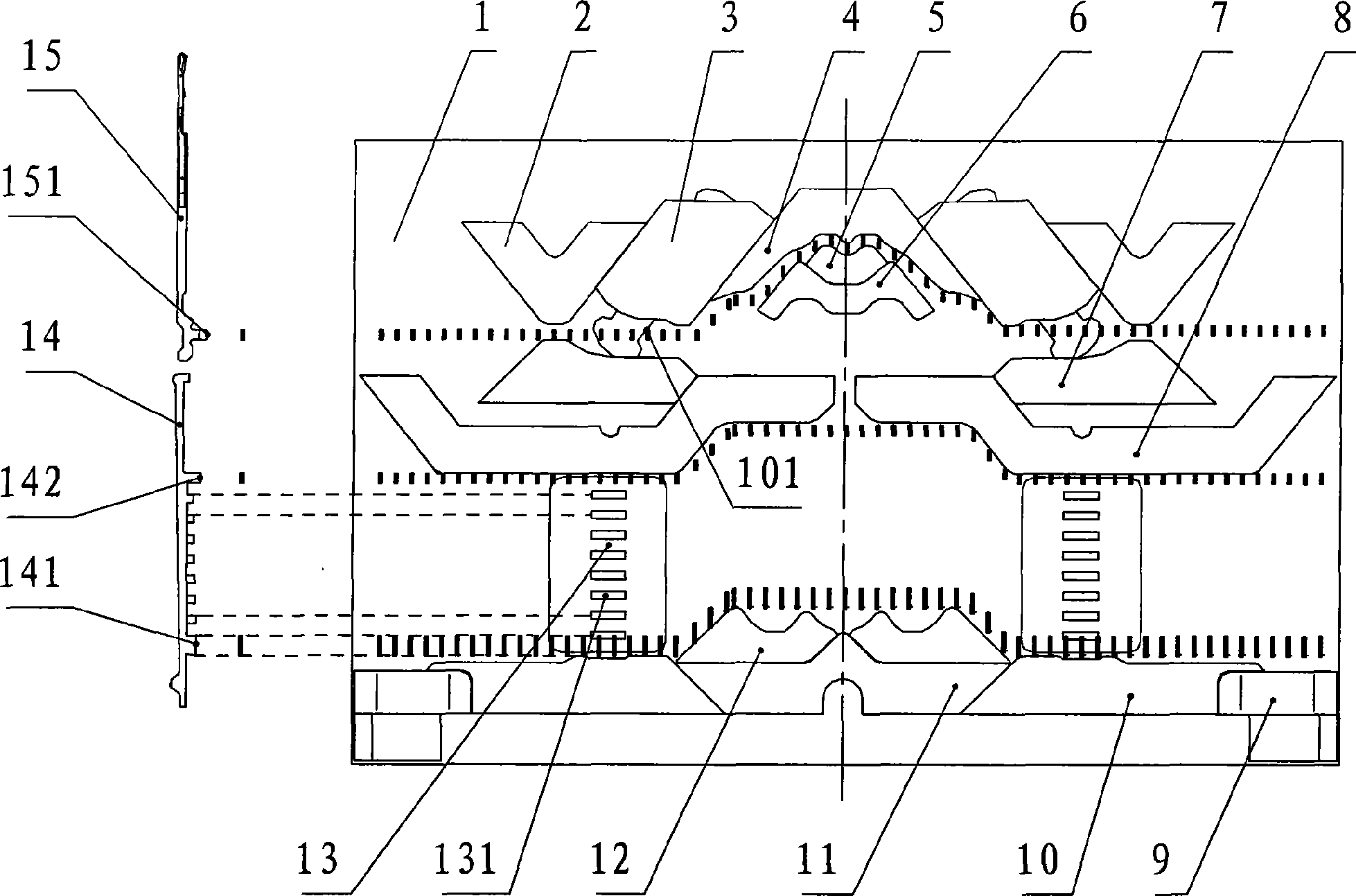

[0020] The knitting mechanism of the computerized flat knitting machine of the present invention includes upper and lower functional areas, the lower functional area is mainly used to control the running track of the needle selector, and the main function of the upper functional area is to control the running track of knitting needles.

[0021] Such as figure 1 As shown, the lower functional area is respectively distributed with a needle selection reset block (9), a reset triangle (8), a needle selection guide triangle (10), a needle selector (13) and a needle guide triangle (11). Fixed and locked on the triangular bottom plate (1); there are eight needle selection pressure plates (131) on the needle selector (13), corresponding to the eight needle selection butts (141) on the needle selection piece respectively; the needle selection pressure plates (131) respectively Controlled by different needle selection electromagnets, when the corresponding knitting needle is about to w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com