Aspheric aperture splicing measuring device based on spherical air-bearing shafts

A technology of aperture splicing and measuring devices, which is applied in the field of optical detection, can solve complex and high-precision, multi-degree-of-freedom adjustment mechanisms and other problems, and achieve the effects of low motion accuracy requirements, cost reduction, and suppression of influence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below in conjunction with the accompanying drawings.

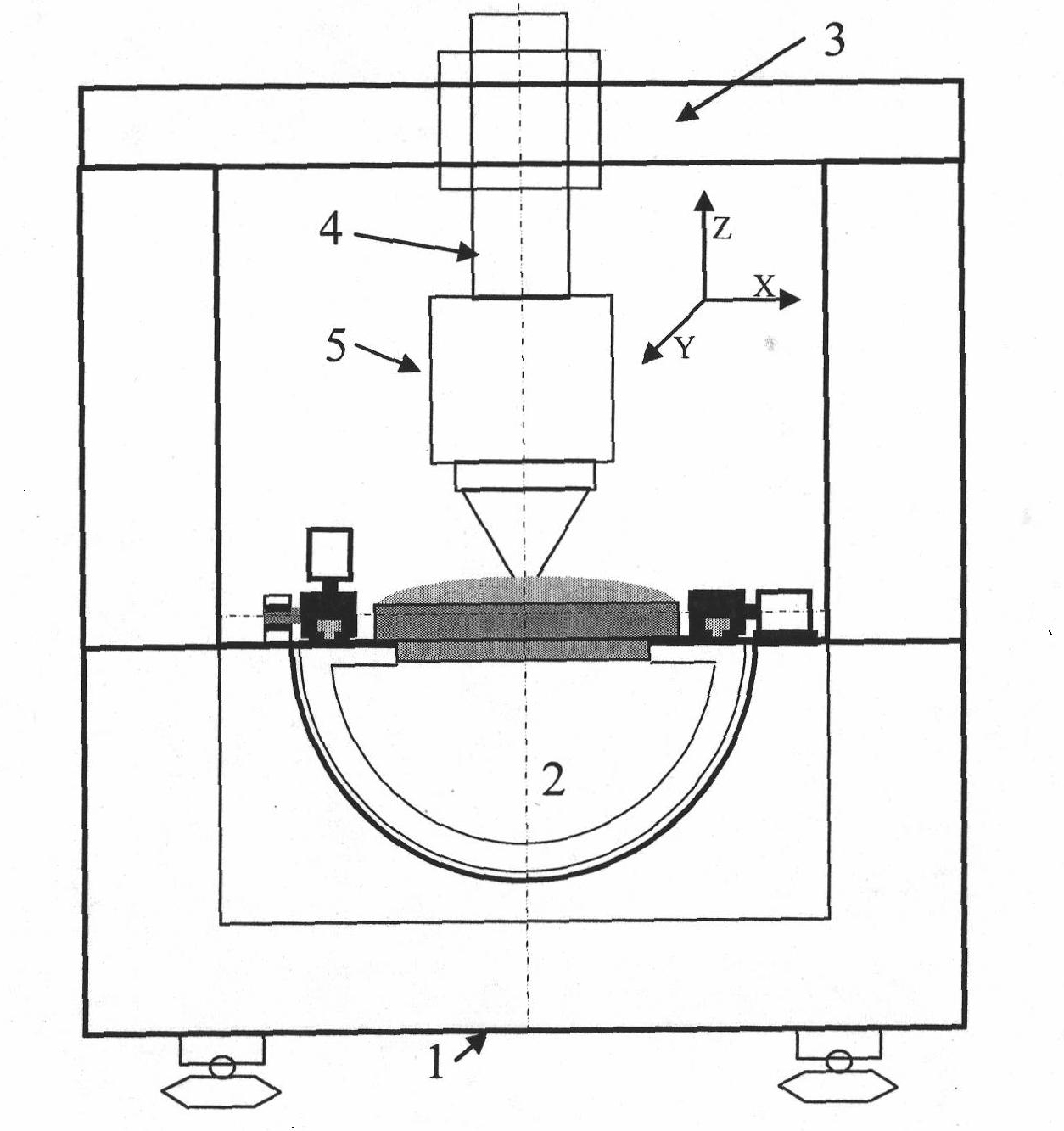

[0021] like figure 1 As shown, the aspheric surface sub-aperture splicing measurement device based on the spherical air bearing axis proposed by the present invention, the spherical air bearing table 2 and the gantry support 3 are installed on the vibration isolation base 1, and the linear air flotation guide rail 4 is fixed in the center of the gantry support 3 At the position, an optical wavefront interferometer 5 is arranged at the lower end of the linear air-floating guide rail 4 .

[0022] The spherical air bearing table 2 is composed of a spherical air bearing shaft 20, an air bearing shaft base 21, a rotating motor 22, a stepping motor 23, a circular guide rail 24, a first guide rail pair 25, a second guide rail pair 26, and a support mechanism 27 Composition; a circular guide rail 24 is fixed on the outside of the table top of the spherical air beari...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com