Magnetoelectric sensor adjusting circuit

A magnetoelectric sensor, magnetoelectric sensor technology, applied in the direction of instruments, electrical control, machines/engines, etc., can solve the problems of economic loss, inability to pre-determine, complicated replacement process, etc., to save maintenance costs and reduce fault diagnosis time. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The preferred embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

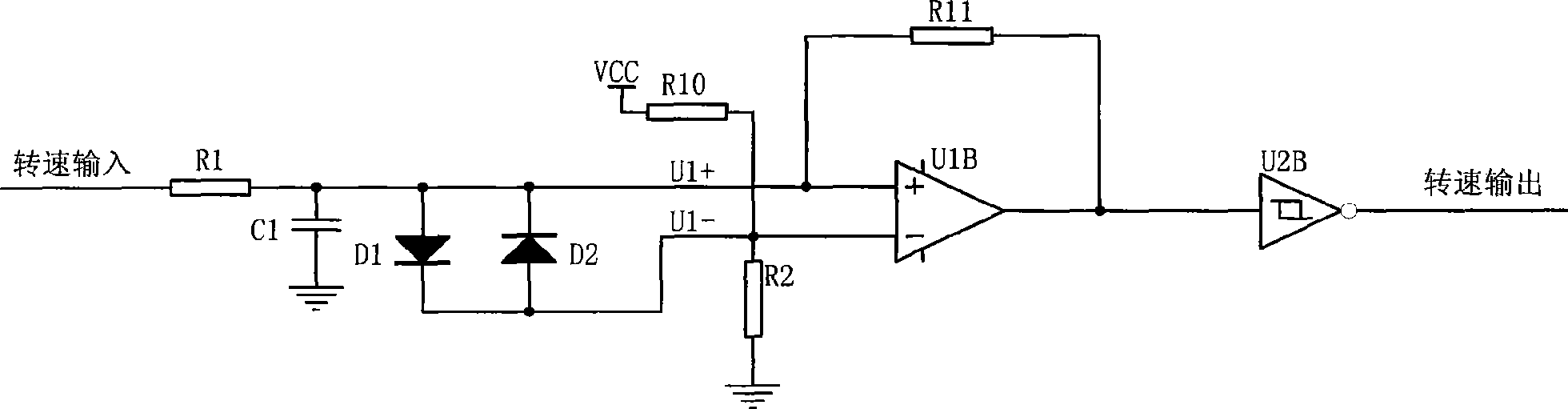

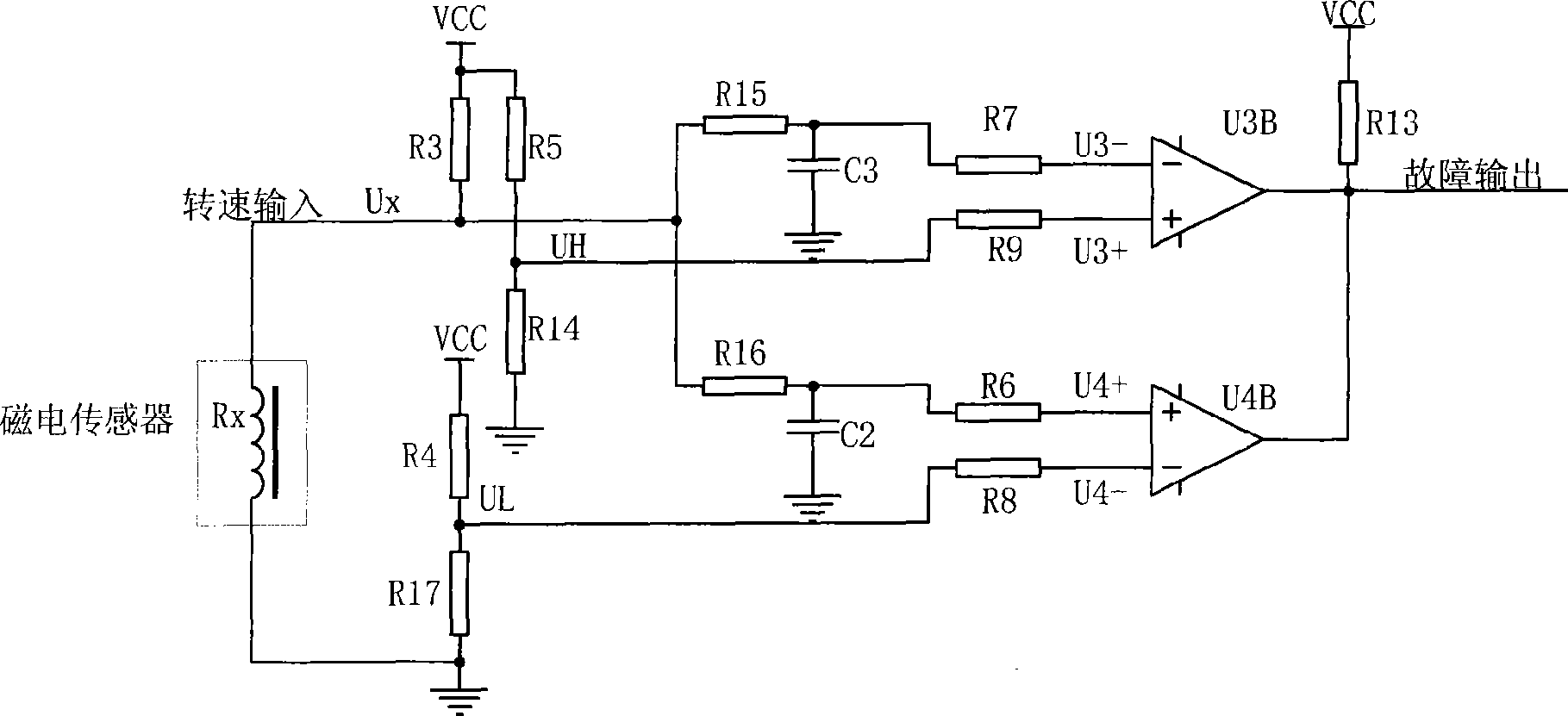

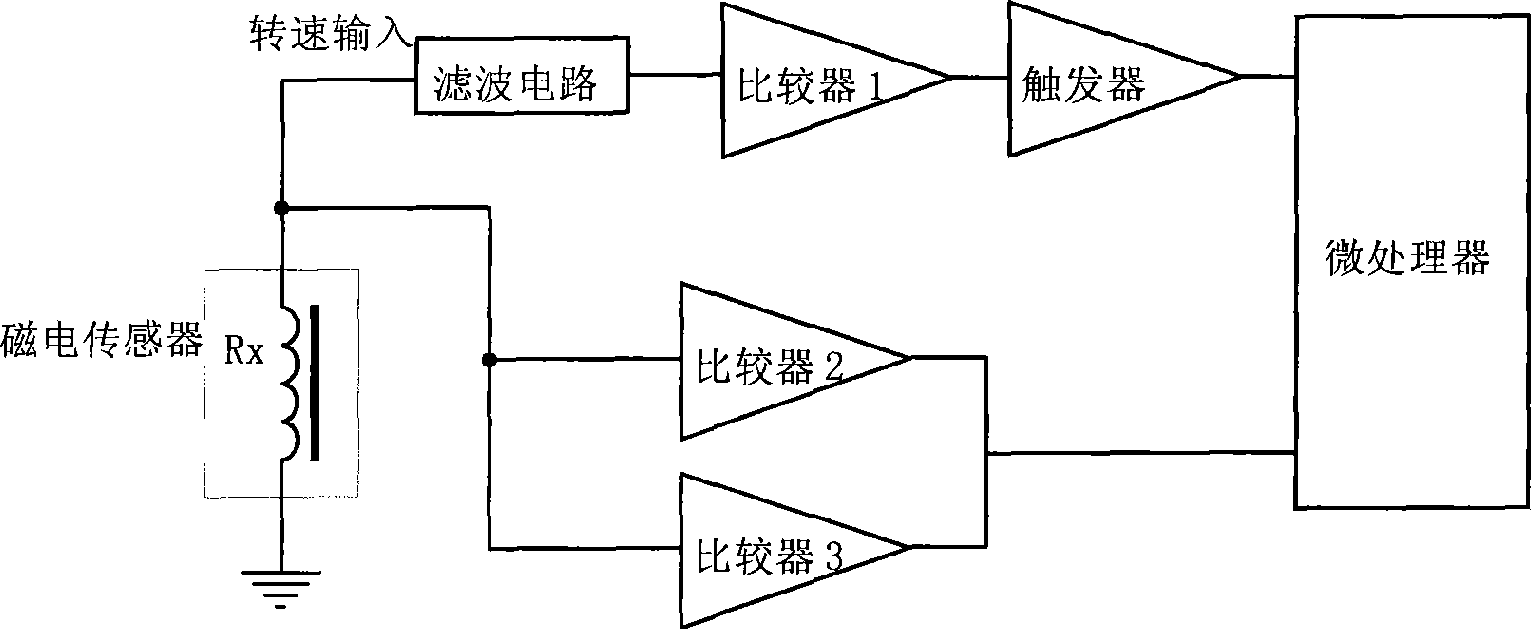

[0013] A magnetoelectric sensor conditioning circuit includes a signal conditioning circuit and a fault diagnosis circuit, both of which use the output of the magnetoelectric sensor as their input.

[0014] like image 3 As shown, the output signal of the magnetoelectric sensor enters the comparator 1 through the filtered current, and the rectangular wave signal is output by comparison, and the trigger performs hysteresis comparison processing on the signal, and then the microprocessor calculates the speed. At the same time, Rx is the equivalent resistance of the magnetoelectric sensor coil. When the magnetoelectric sensor coil has no signal, the voltage division signal on the internal resistance Rx of the sensor is compared with the upper limit voltage by comparator 2, and the lower limit voltage is compared by comparator 3. When When the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com