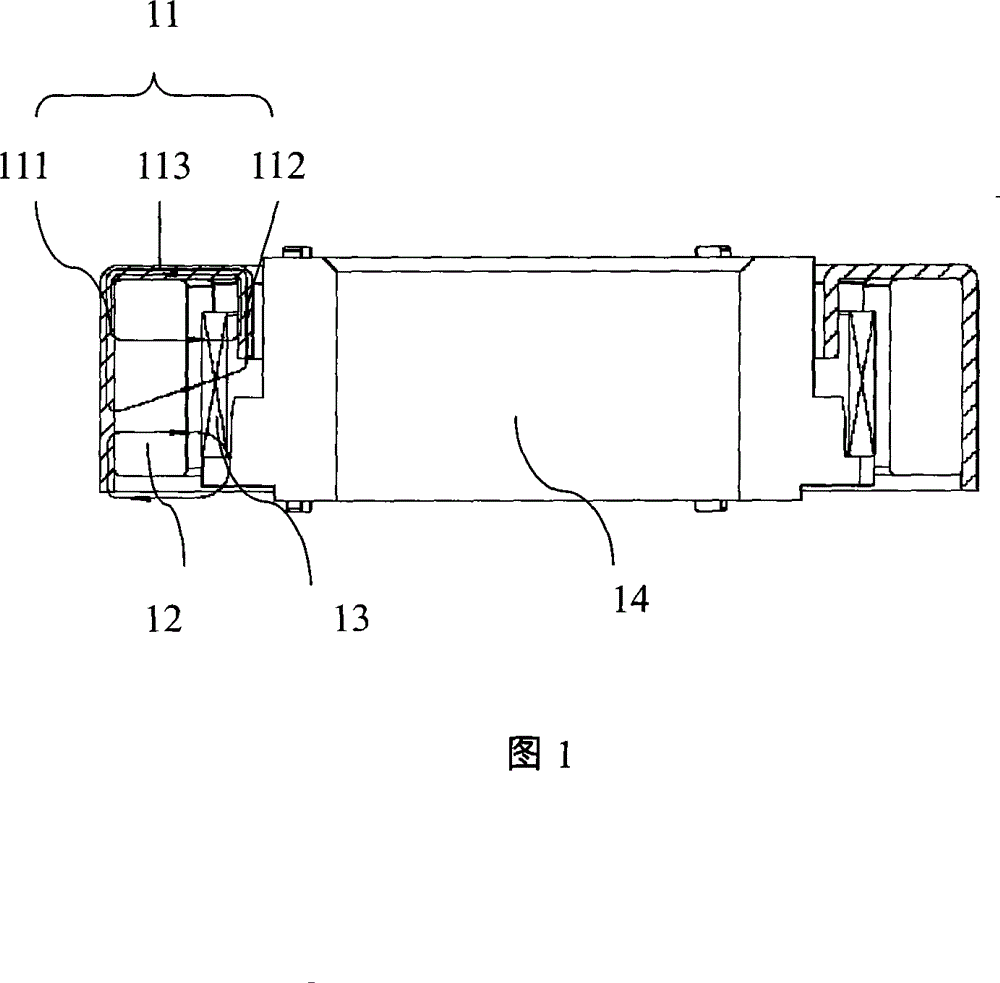

Lens driving device

A lens drive device and lens technology, applied in the field of photography, to achieve the effects of increased magnetic field utilization, enhanced magnetic field strength, and improved EMI

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

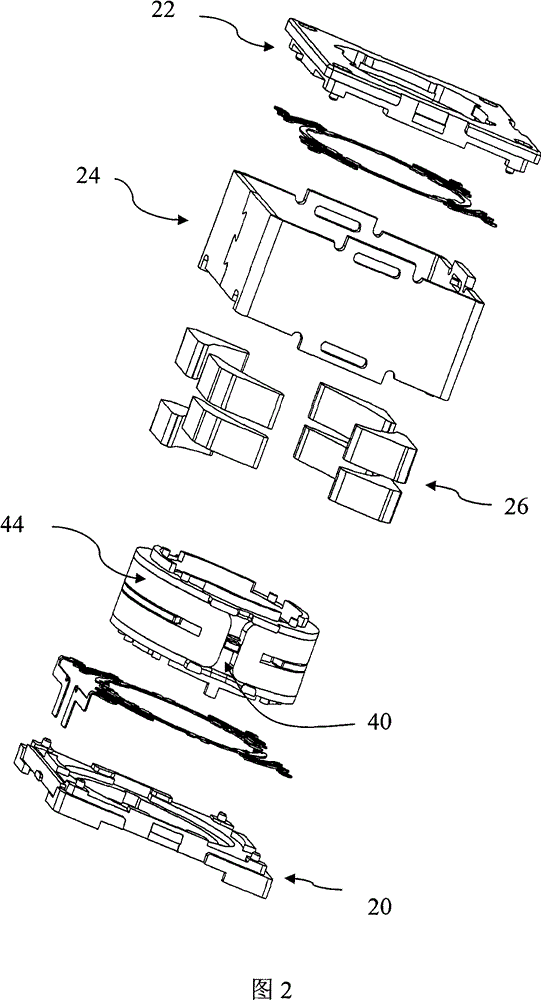

Method used

Image

Examples

Embodiment approach

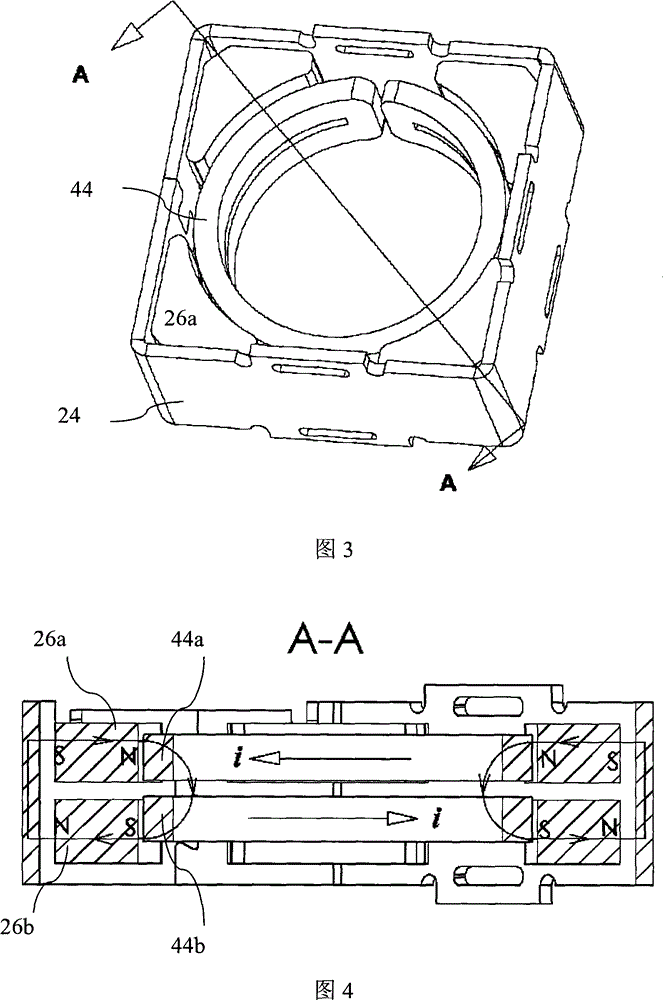

[0022] see Image 6 , as another embodiment of the present invention, the moving part may also include two semi-cylindrical coils, which are respectively fixed to both sides of the lens holder 40 by pasting or the like, and each semi-cylindrical coil corresponds to two sets of magnets.

[0023] see Figure 7 , as another embodiment of the present invention, the moving part may also include four arc-shaped coils, each coil corresponds to a group of magnets, and the currents flowing through the four coils have the same direction, that is, all of them are viewed from the same direction. Clockwise or all counterclockwise.

[0024] In the above embodiment, the lens driving device can be approximately square, cylindrical or other shapes, correspondingly, the iron shell 24 can be approximately square, circular or other shapes, and the lens holder 40 can be square, cylindrical or other shapes, The plurality of magnets 26 can be divided into several groups along the circumference of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com