Drive train

A powertrain and torque technology, applied in the field of motor vehicles, can solve problems such as loss of comfort, failure overload, wrong interpretation of engine torque, etc., and achieve the effect of optimizing structural space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

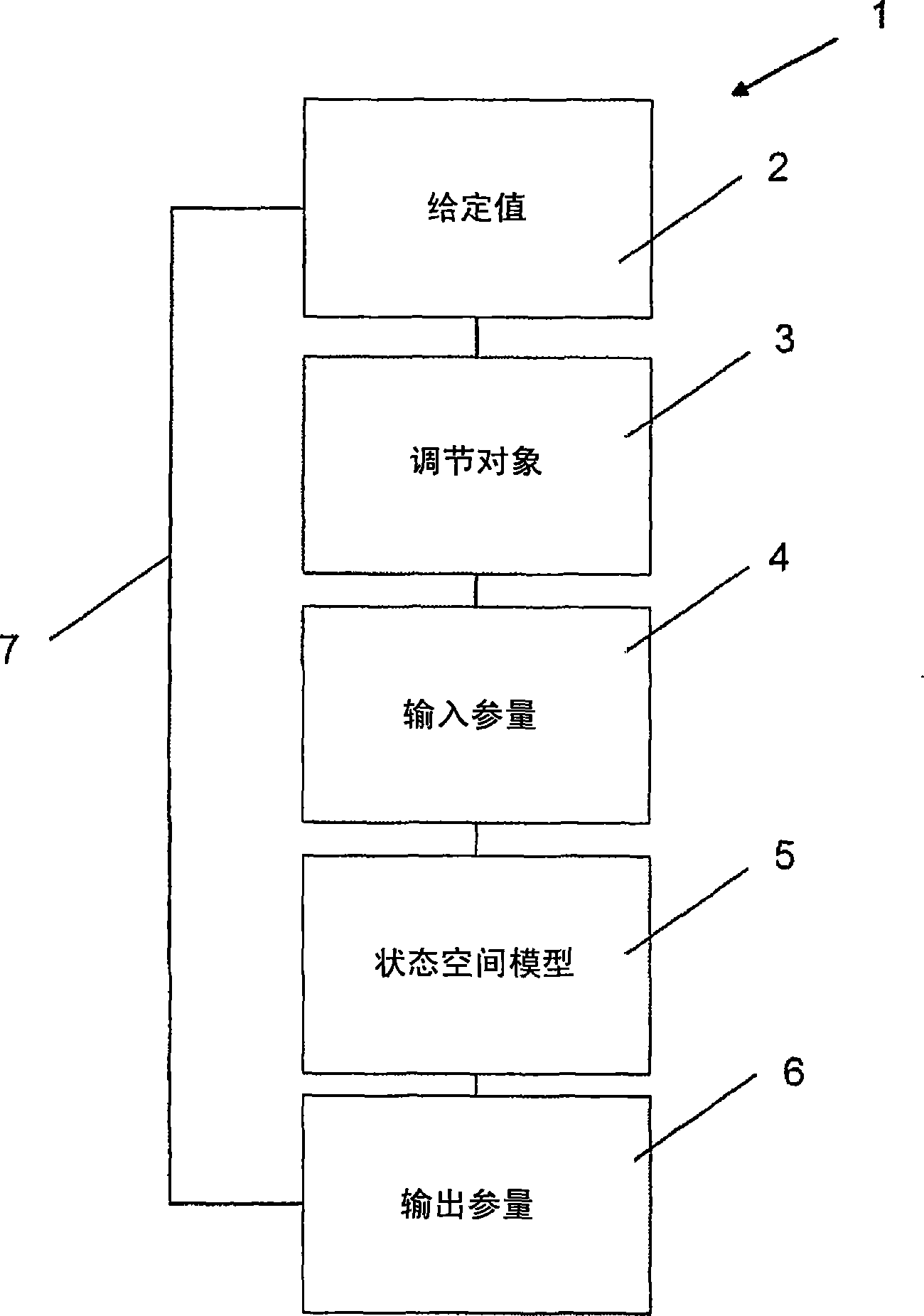

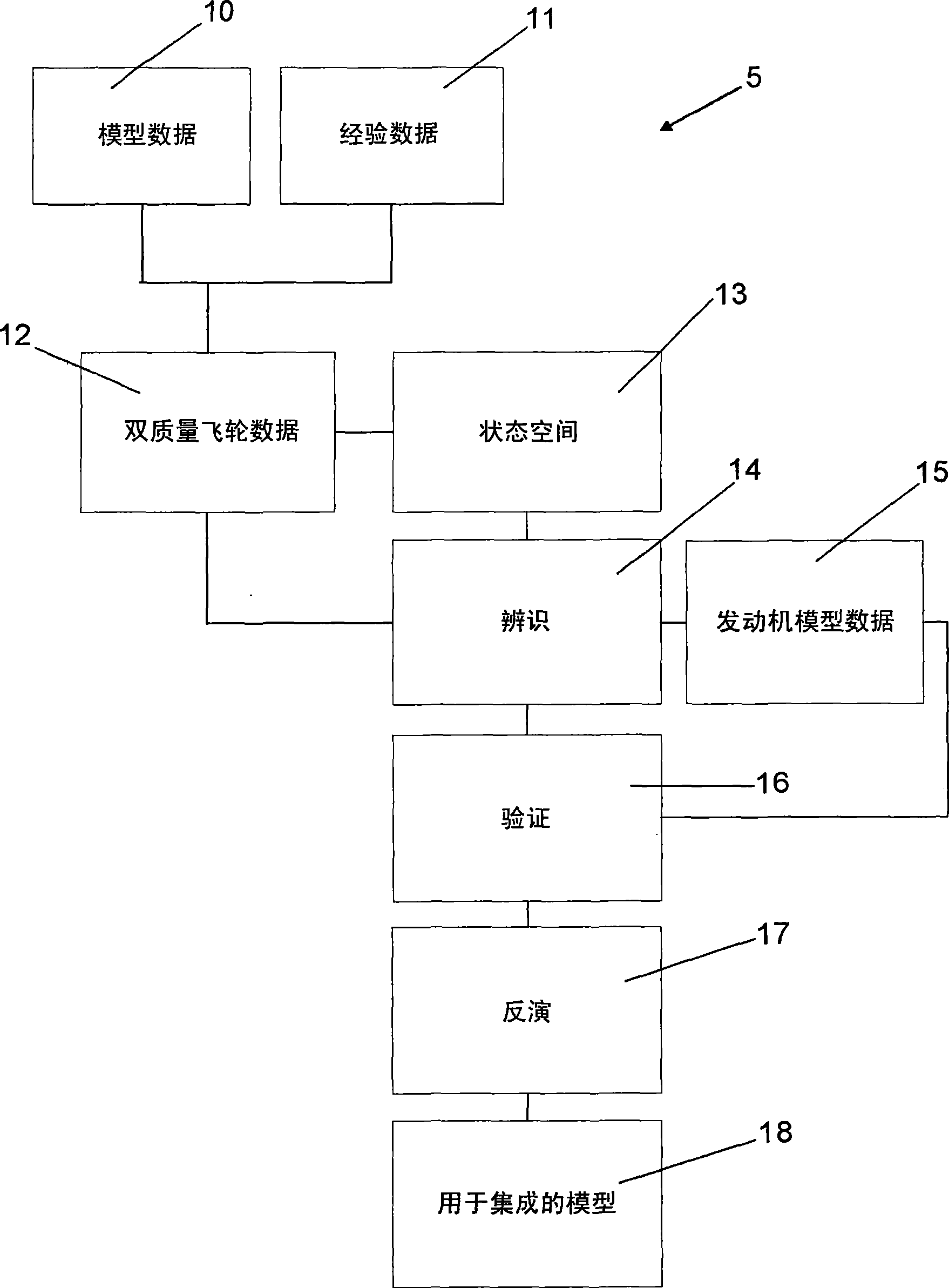

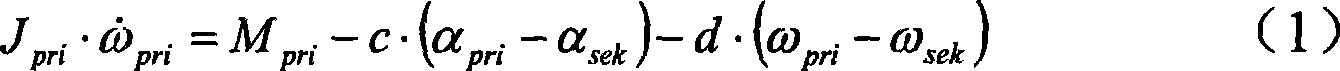

[0065] figure 1 An exemplary flow of regulation 1 according to the present invention is shown in . In box 2, a setpoint value for regulation 1 is provided, which can be calculated and output as an initial value by the engine control system. In the case of an internal combustion engine, the desired value can be a desired torque, which is predetermined by the driver using the accelerator pedal. Correspondingly, the desired torque can be adjusted as a function of other parameters such as engine characteristic factors, gears engaged in the transmission, vehicle operating conditions, road surface conditions and the like. In block 3 , setpoint 2 is used for the control object, which may include the internal combustion engine as well as downstream components such as clutches, dual-mass flywheels or powertrain components such as auxiliary units and downstream transmissions. In the case of a dual-mass flywheel, the setpoint output to the internal combustion engine is in particular co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com