Apparatus for manufacturing molten irons and method for manufacturing molten irons using the same

A technology of equipment, hot metal, applied in the direction of lighting and heating equipment, sustainable manufacturing/processing, furnace type, etc., can solve the problem of diffusion, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

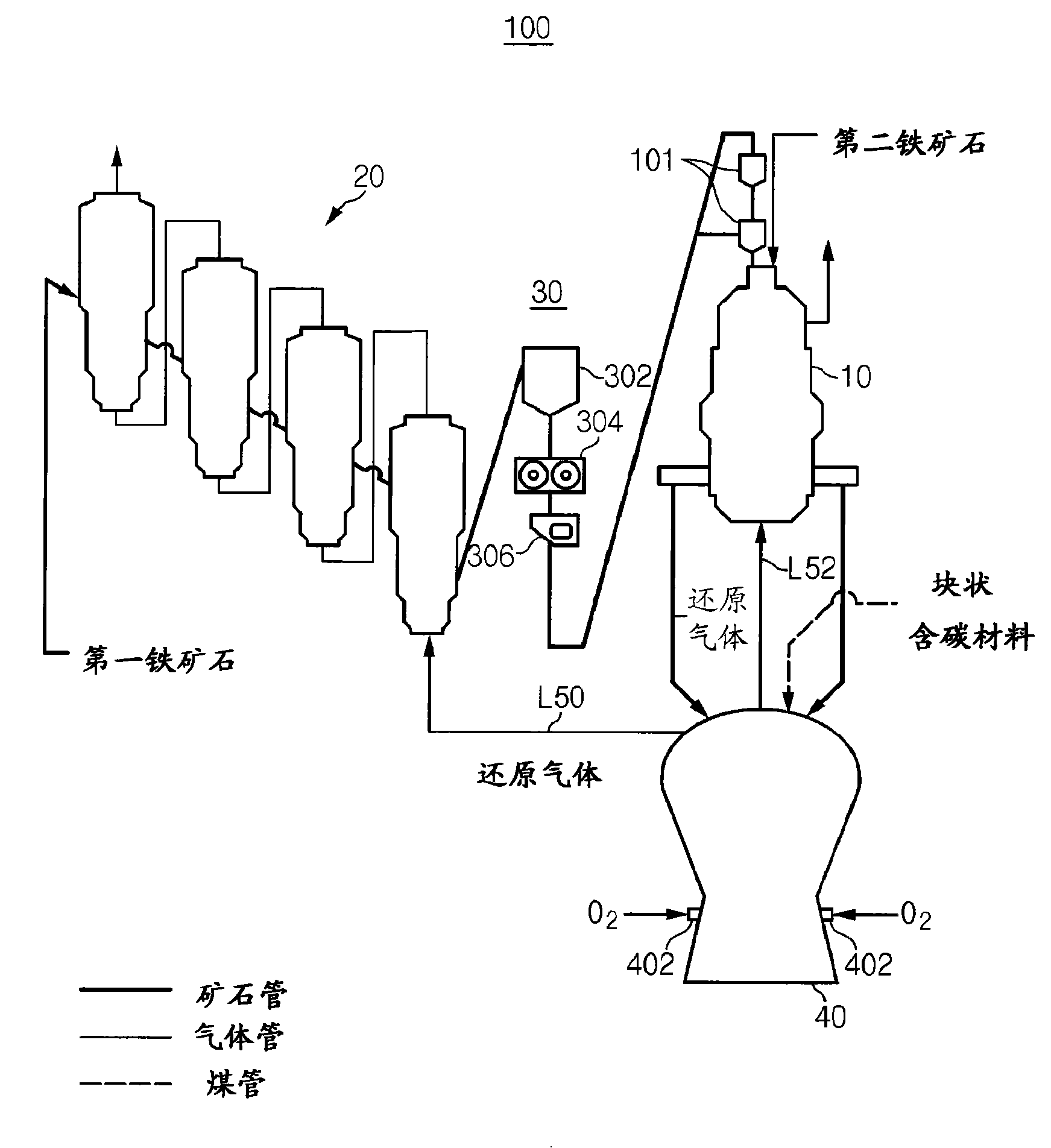

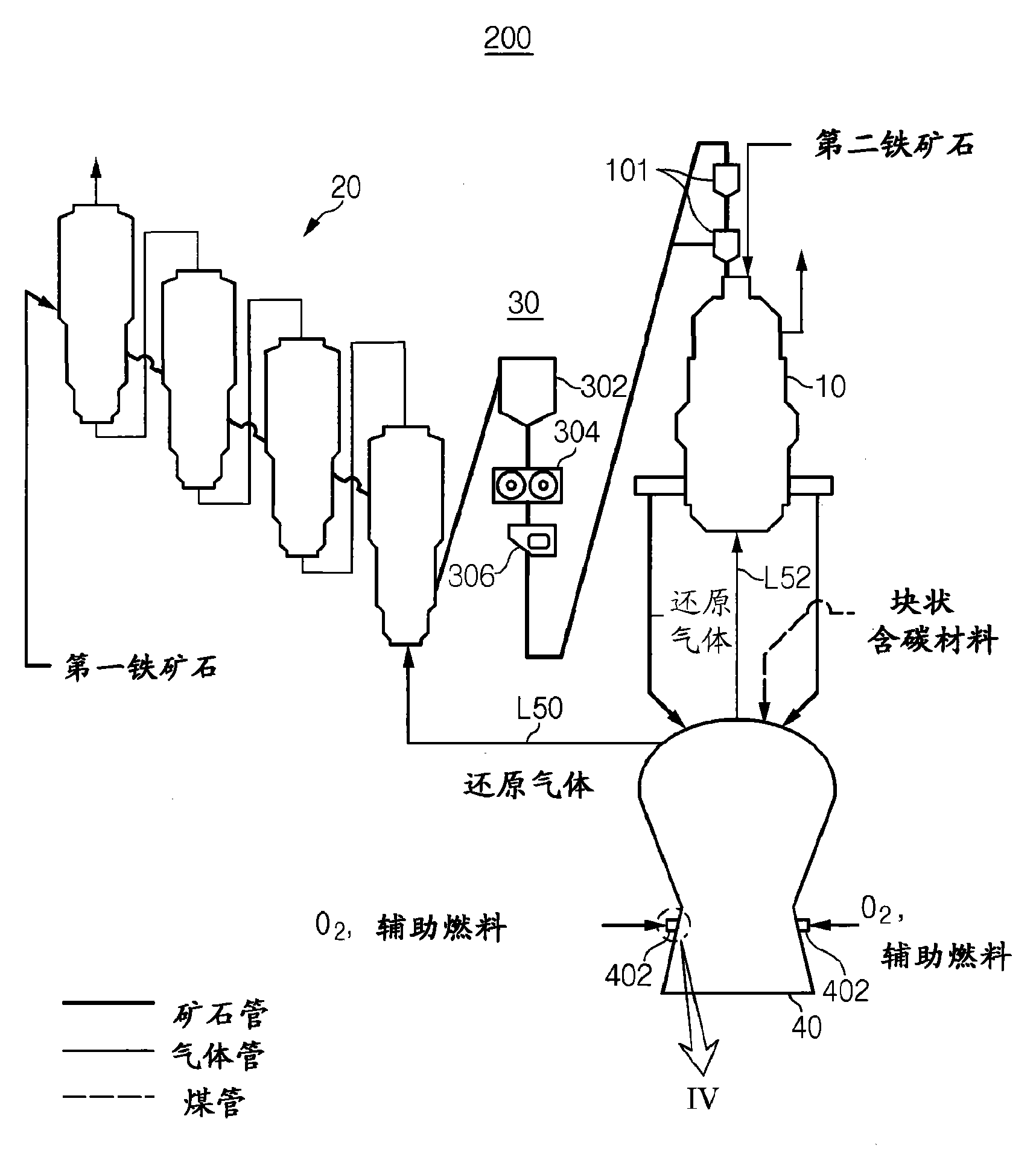

[0040] The following will refer to Figure 1-7 Exemplary embodiments of the present invention are explained. The exemplary embodiments are only intended to describe the present invention, and the present invention is not limited thereto.

[0041] figure 1 An apparatus 100 for manufacturing molten iron according to a first exemplary embodiment of the present invention is schematically illustrated. figure 1 The apparatus 100 for manufacturing molten iron illustrated in FIG. 1 is only intended to describe the present invention, and the present invention is not limited thereto. Therefore, the structure of the user's equipment 100 for making molten iron can be modified into other forms.

[0042] exist figure 1 In , the ore pipe through which iron ore passes is marked as a thick solid line for convenience, and the gas pipe through which gas passes is marked as a thin solid line. In addition, the coal pipes through which the coal passes are marked with dashed lines.

[0043] ex...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com