Differential confocal curvature radius measurement method and device

A differential confocal, radius of curvature technology, used in measuring devices, optical devices, instruments, etc., to achieve high stability, enhance fixed focus sensitivity, and reduce the effect of lens focal depth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

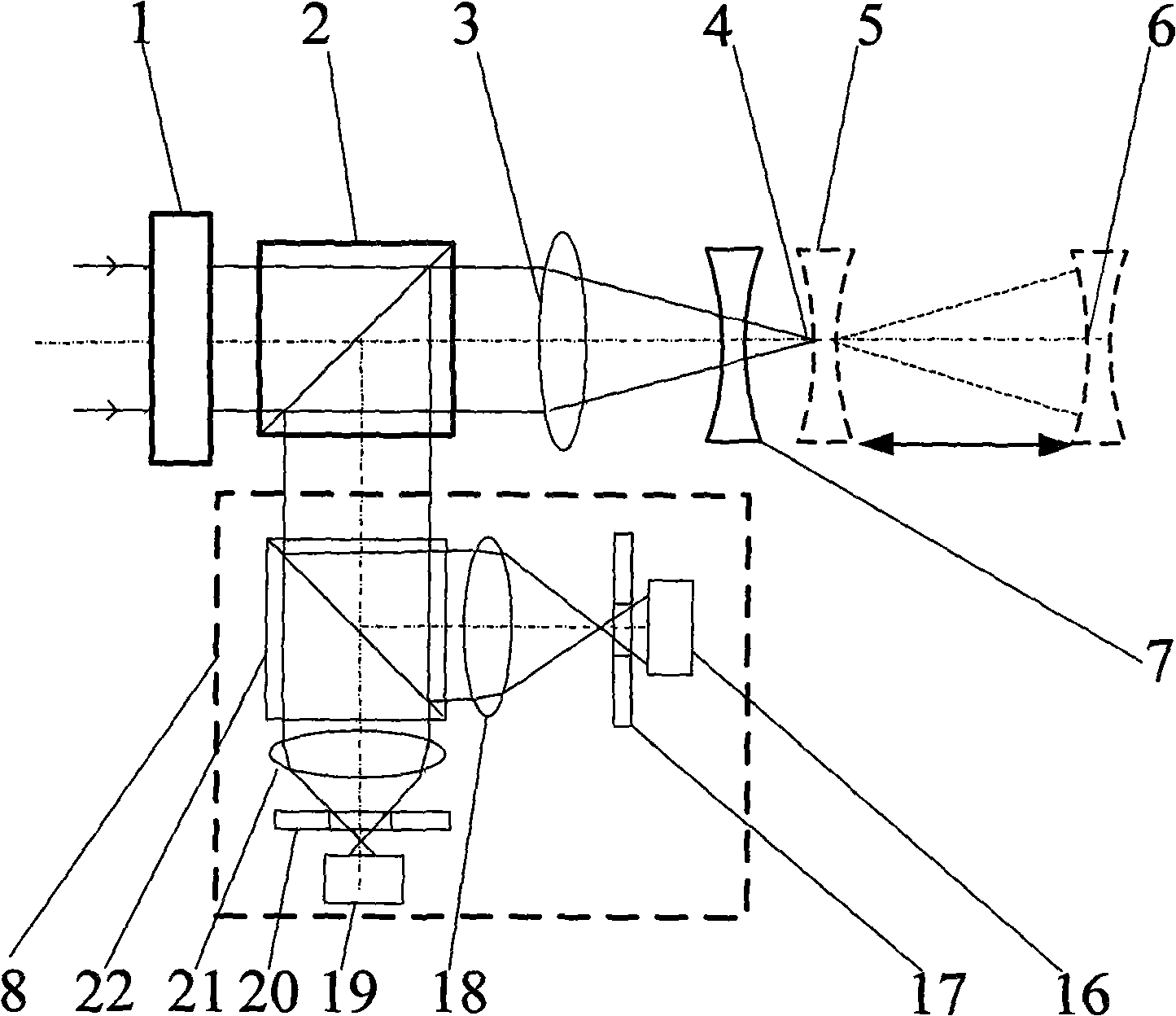

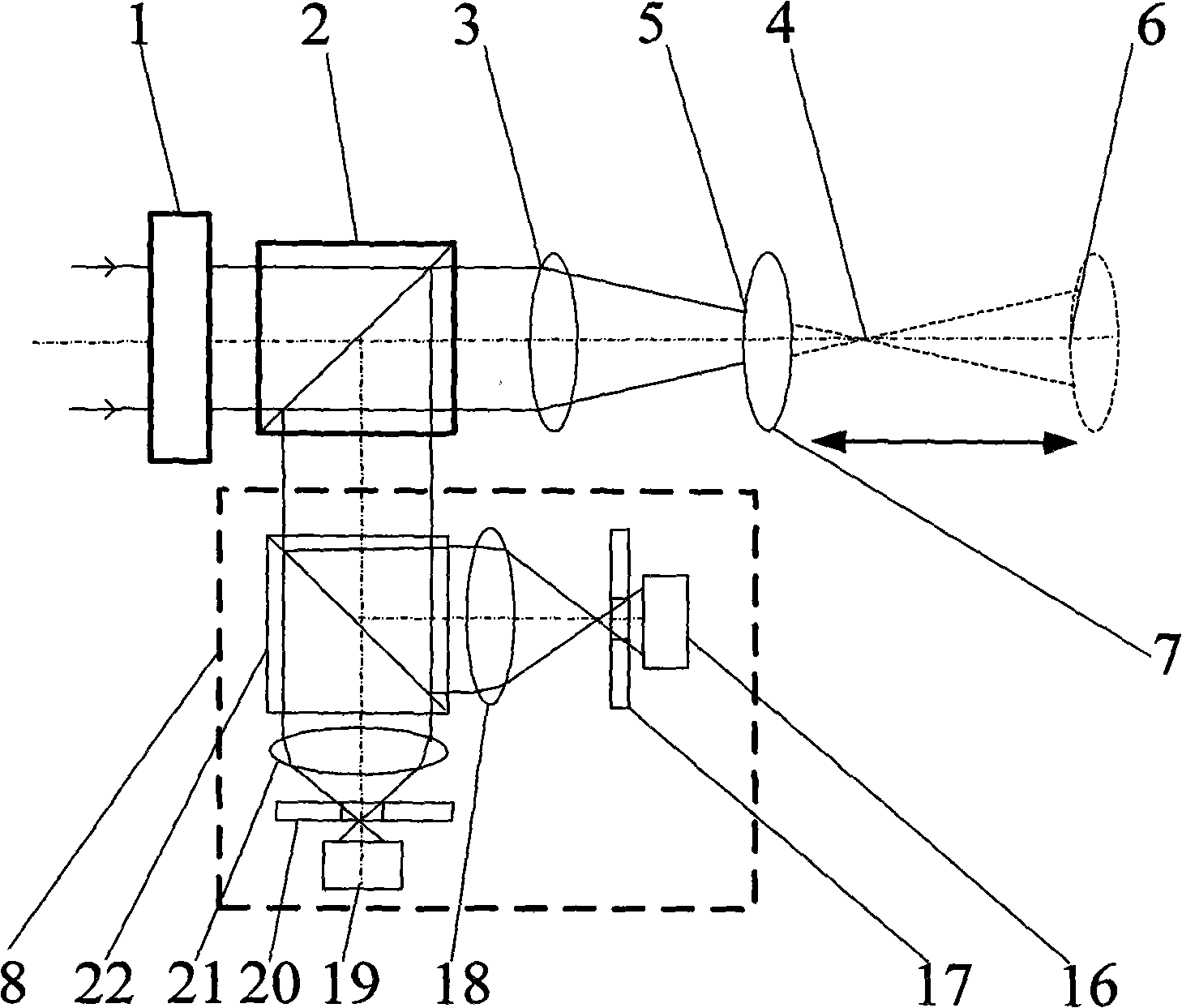

[0044] In this embodiment, differential confocal curvature radius measurement is performed on a concave lens. Such as Image 6 Shown is a differential confocal radius of curvature measurement method, the measurement steps are:

[0045] First, adjust the optical system before the measurement, turn on the light source 11, the emitted parallel light passes through the beam splitting system composed of the polarizing beam splitter 12 and the 1 / 4 wave plate 13, converges at the focal point 4 through the converging lens 3, and places the measured lens Near the focus position 4, after the light is reflected by the measured lens 7, it is reflected by the 1 / 4 wave plate 13 and the polarization beam splitter 12 and enters the beam splitter 22 of the differential confocal system; the beam splitter 22 divides the light into two paths, wherein One path of transmitted light passes through the lens 21 and the pinhole 20 to illuminate the photoelectric sensor 19, and the other path of reflec...

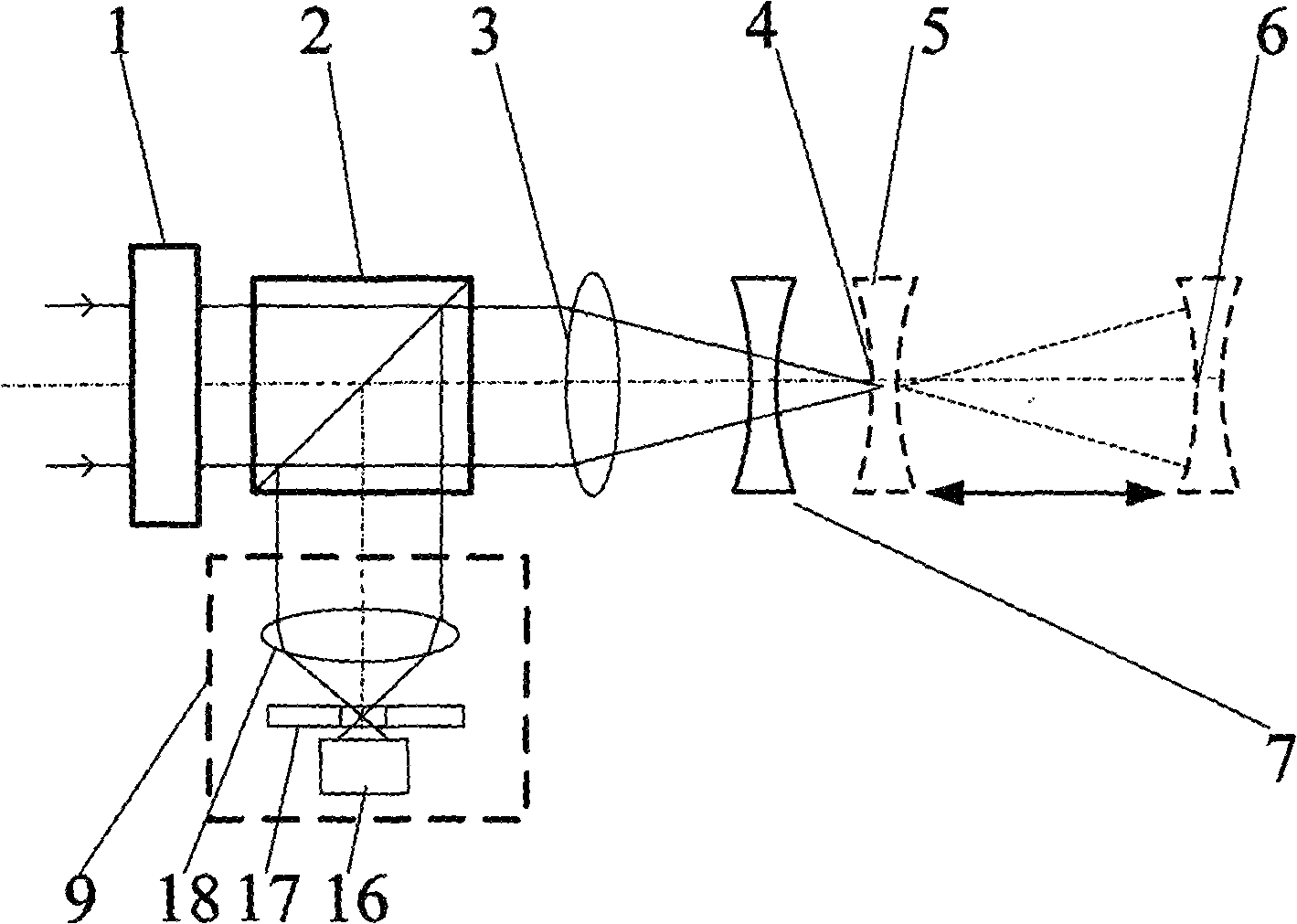

Embodiment 2

[0054] This embodiment is aimed at the measurement of the confocal curvature radius of the concave lens. According to the embodiment of the method for measuring the radius of curvature of the differential confocal, in the process of adjusting the optical path, the differential confocal system 8 in Embodiment 1 can be replaced by the confocal system 9, and the condenser lens 18 in the confocal system converges the light rays and converges them. The light passes through the pinhole 17 to illuminate the photoelectric sensor 16;

[0055] Such as Figure 7 As shown, in the measurement process, the lens under test 7 is scanned and moved along the translation stage 14 in the direction of the optical axis of the converging lens 3, and the confocal system determines the first point of the lens under test by detecting the maximum point of the corresponding signal of the photoelectric sensor 16. Focus position 5, responding to signals such as Figure 9 shown.

[0056] Then, the gratin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com