High temperature fatigue test clamp for metal thin wall equal-wall thickness tube

A fatigue test, metal thin technology, used in the analysis of materials, the use of stable tension/pressure to test the strength of materials, measurement devices, etc., can solve the problems of long tube sample, poor sample size adaptability, large sample consumables, etc. , to achieve the effect of simple structure, saving sample material and wide adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Below in conjunction with accompanying drawing and embodiment the utility model is further described.

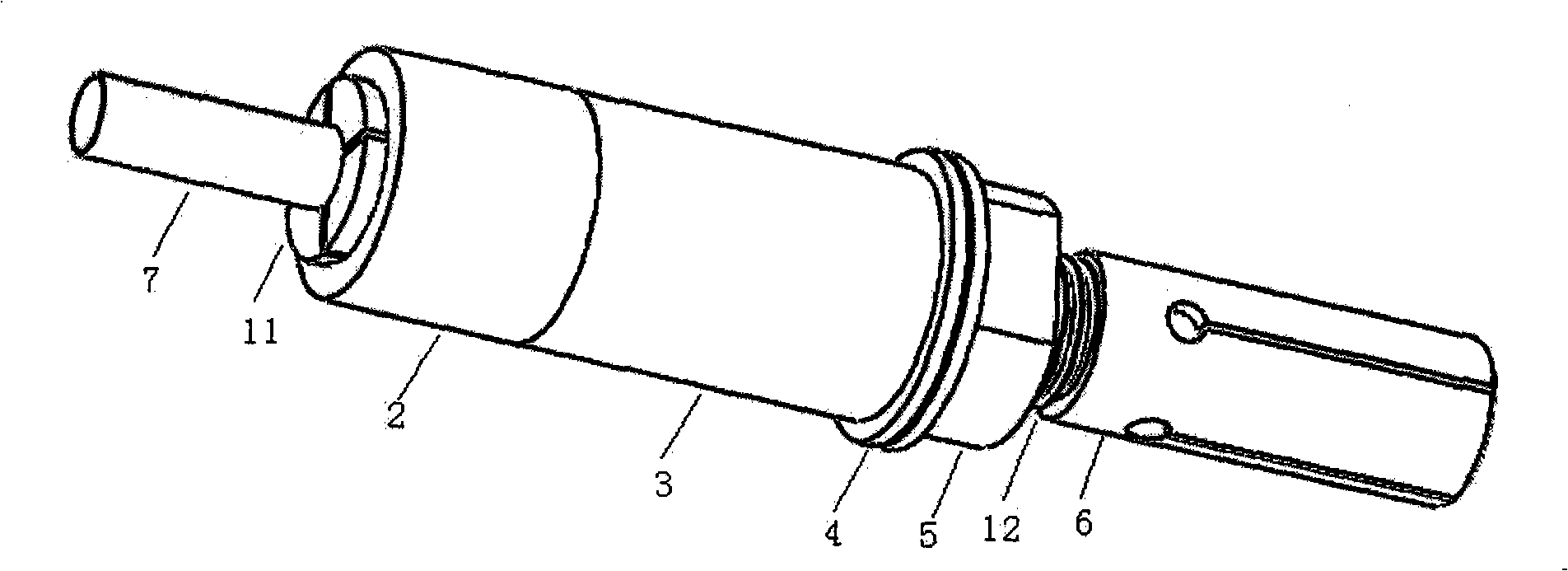

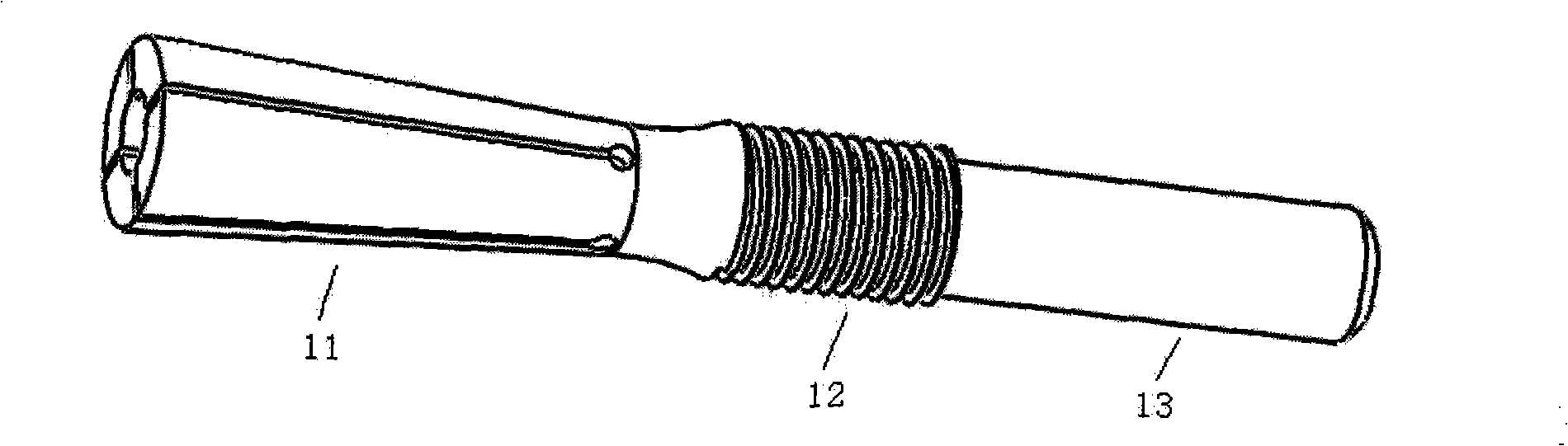

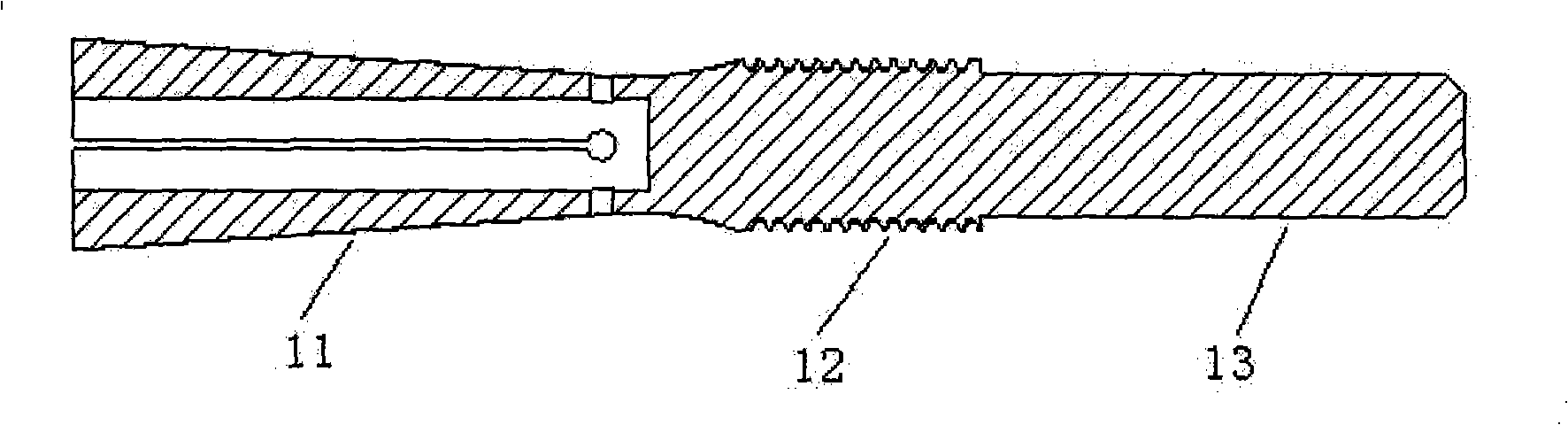

[0014] combine Figure 1 to Figure 5 The basic structure and specific embodiments of the invention can be seen. A high-temperature fatigue test fixture for metal thin-walled and equal-thickness pipes has a main shaft (1), and the main shaft has a tapered clamping sleeve (11), a central threaded section (12) and a clamping section (13); a locking sleeve (2 ) and the transition sleeve (3) are sequentially sleeved on the tapered clamping sleeve (11) of the main shaft; the lock nut (5) is screwed on the middle threaded section (12) of the main shaft; ) is socketed on the clamping section (13) of the main shaft; the main shaft tapered clamping sleeve (11) is an elastic mechanism that can change the radial scale, and is generally a multi-lobed symmetrical layout structure, and a four-lobed outer cone is used here Structure, the symmetrical hole at the root of the cone can...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com