Combined polarization plate used for microphone and manufacturing method thereof

A microphone and miniature technology, which is applied in the direction of electret electrostatic transducers, sensors, electrical components, etc., can solve the problems of low process efficiency of insulating gasket 4, small diameter of insulating gasket 4, and poor process operability, so as to eliminate products Defective, reduce the production process and production cycle, improve the effect of quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Hereinafter, the present invention will be described in detail based on the drawings, and the purpose and effects of the present invention will become more apparent.

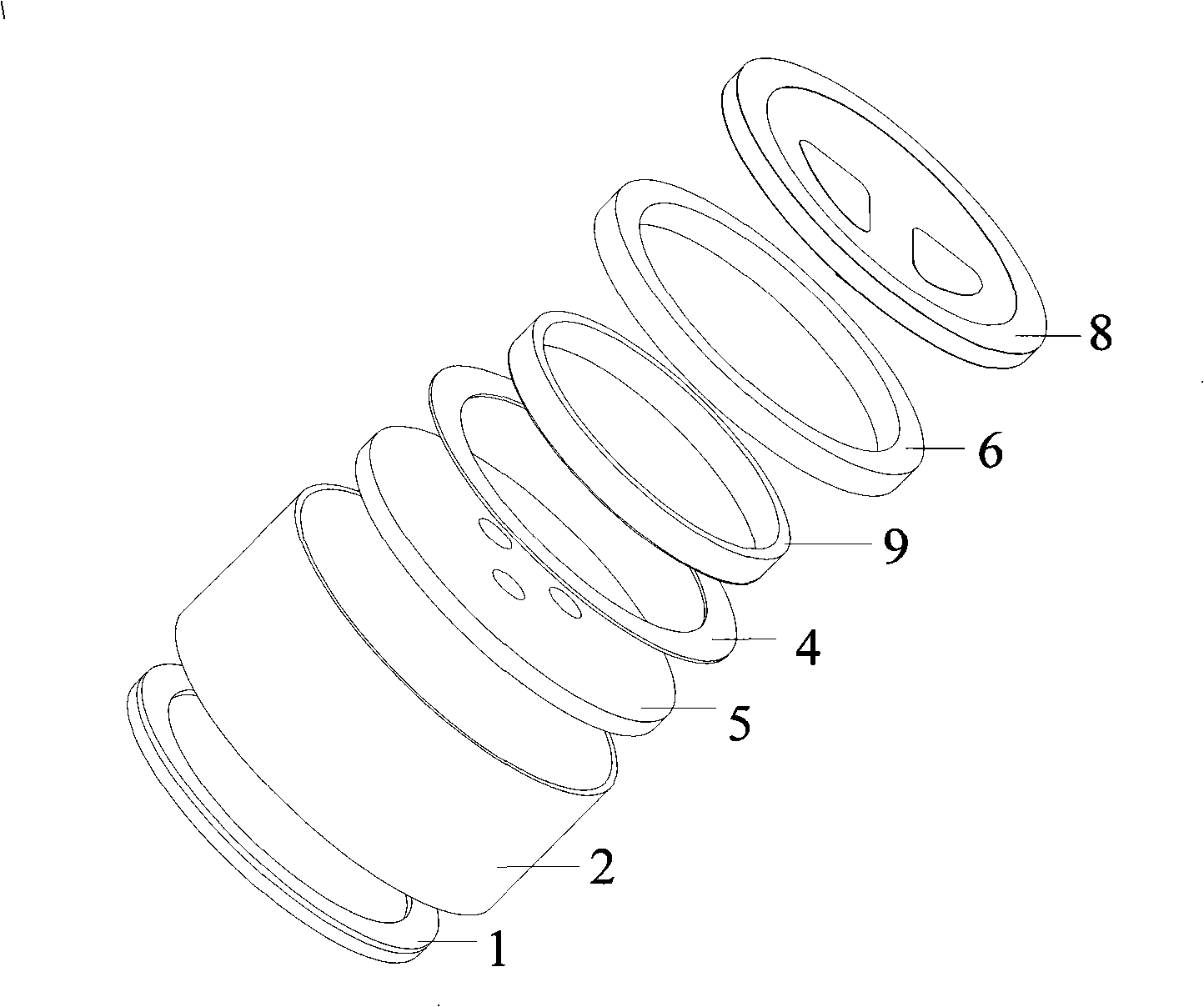

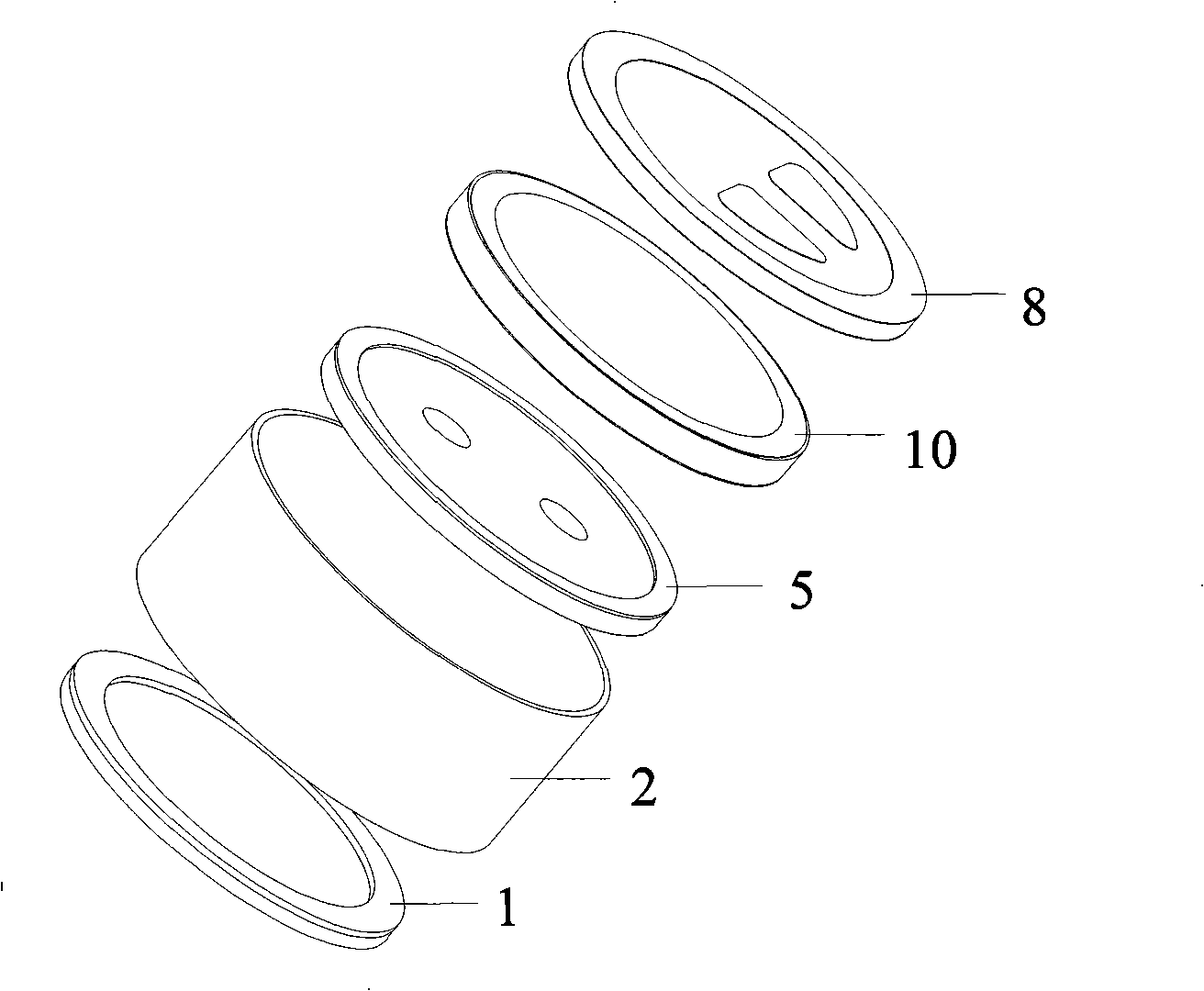

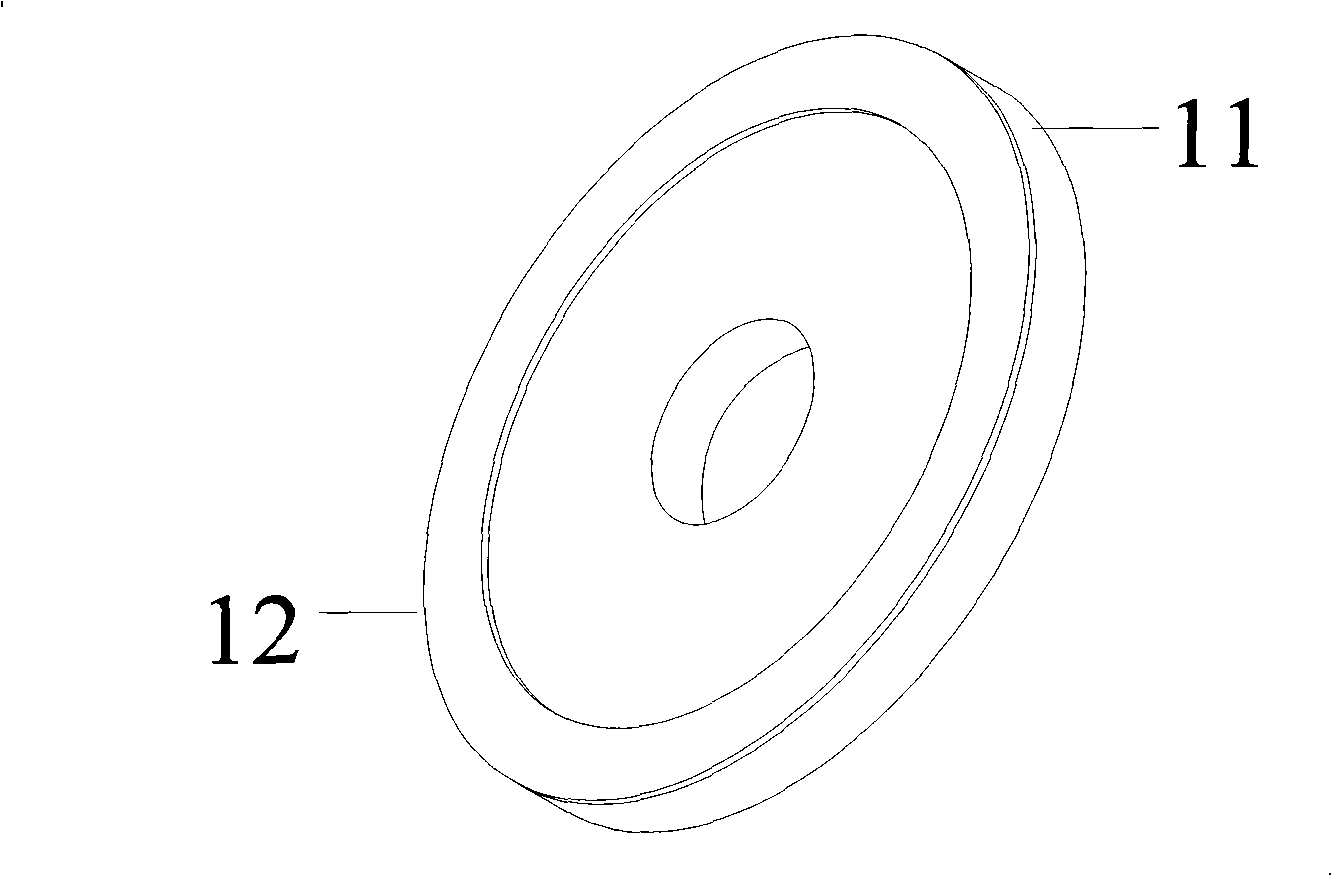

[0023] Such as figure 2 As shown, the microphone using the combined polarization plate of the present invention includes: dustproof or waterproof cloth 1, housing 2, combined polarization plate 5, printed circuit board 8, insulating film ring 10, and one end of the housing 2 is provided with dustproof or waterproof Cloth 1, the housing 2 is sequentially provided with a combined polarization plate 5, an insulating film ring 10, and a printed circuit board 8. The other end of the housing 2 is sealed. The combined polarization plate 5 includes a polarization plate and an insulating layer. The polarization plate is made of a metal plate. It is composed of a polarizing film, and an insulating layer that is 0.01mm~0.10mm higher than the polarizing film is provided on the polarizing film surface of the polarizing p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com