Special man-made feather for badminton and badminton made thereby

A technology of artificial feathers and shuttlecocks, applied in the field of badminton, can solve the problems of overweight wing units, affecting flight performance, and heavy bamboo sticks, etc., and achieve the effect of simple production, firm connection and good durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

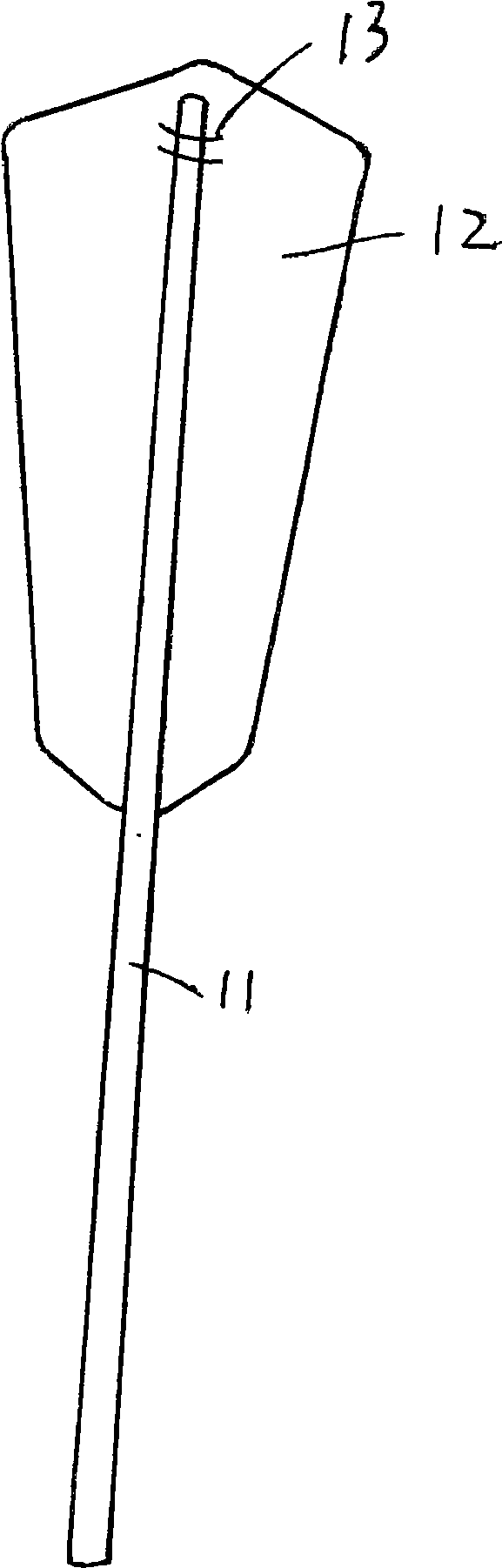

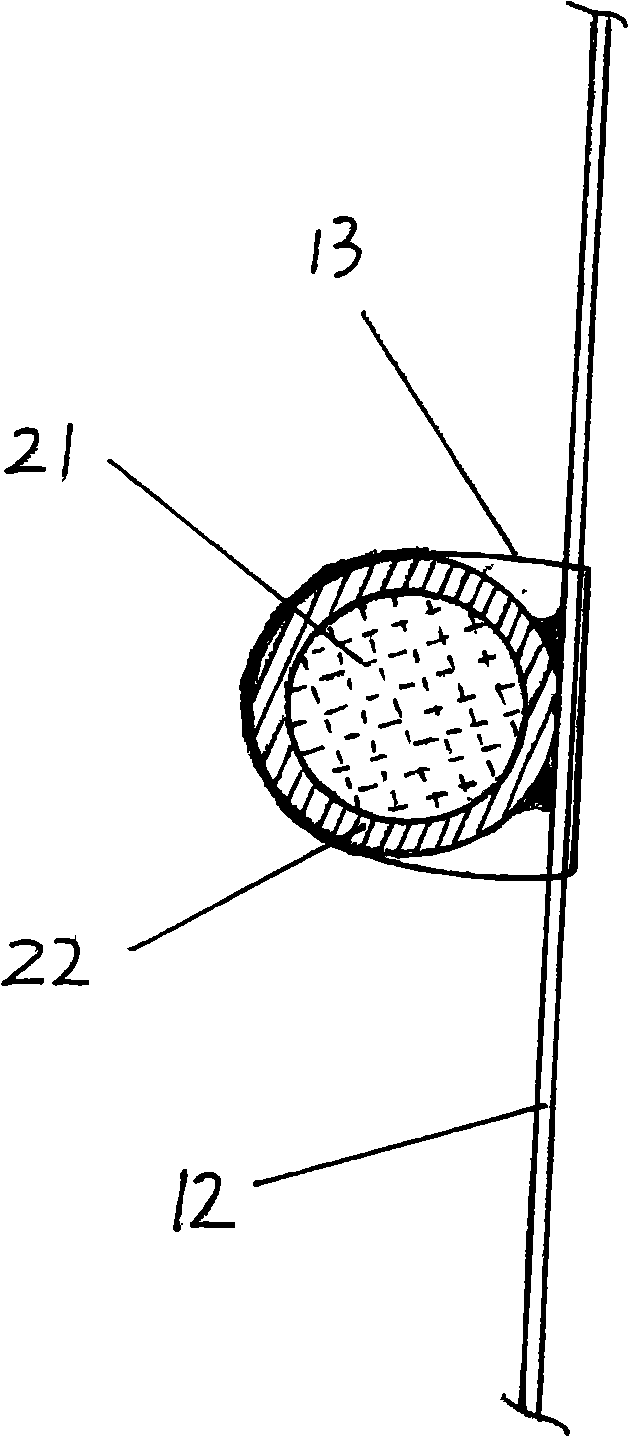

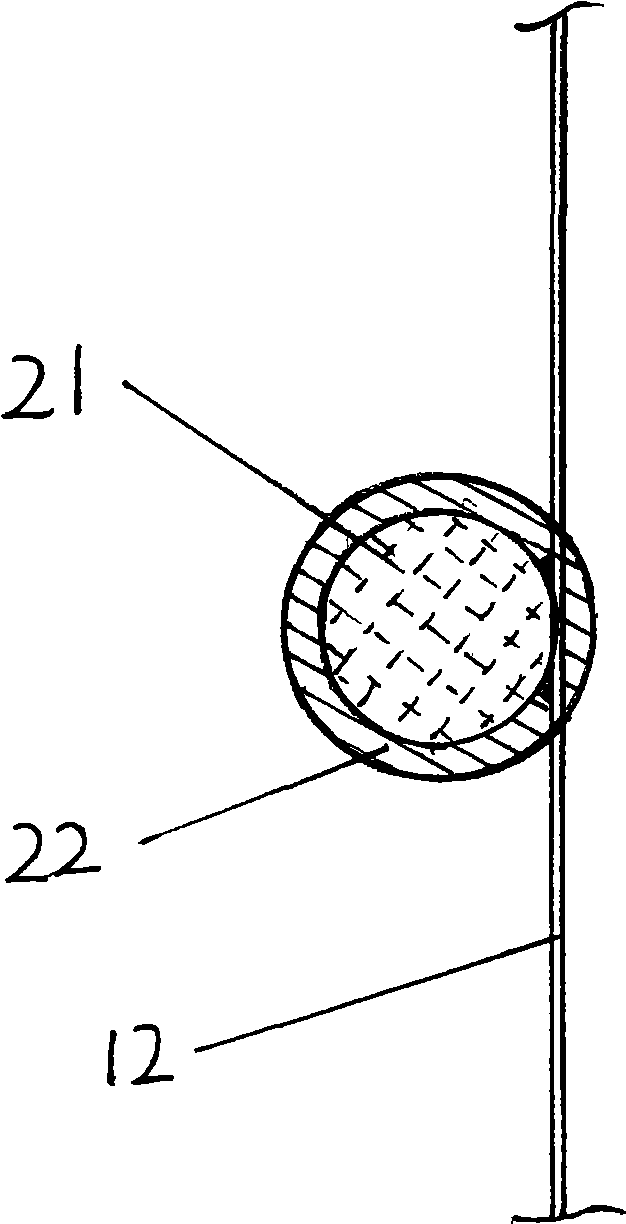

[0048] A kind of artificial feather of the present invention, as figure 1 and figure 2 As shown, its pinna 12 is made of polyester spinning cloth, and the feather stem 11 is a leather-wrapped structure, the feather stem inner core 21 is made of glass fiber reinforced composite material, and the outer cladding 22 is made of polypropylene plastics, Polypropylene plastic is also called PP plastic, and the artificial feather has a reinforcing member 13 of a thin thread stitching structure positioned at the feather stalk head position.

[0049] The specific manufacturing process of this artificial feather is:

[0050]In the first step, the continuous filament glass fiber is selected as the reinforcing material, the unsaturated polyester resin is selected as the matrix material, and the thin rod of the glass fiber reinforced composite material is produced by the pultrusion process, which is used as the inner core 21 .

[0051] In the second step, PP plastic is selected as the mat...

Embodiment 2

[0059] A kind of artificial feather of the present invention, its cross section is as image 3 As shown, the pinna 12 is made of polyester spun cloth, the feather stem 11 is a leather core structure, the inner core 21 is made of glass fiber reinforced composite material, and the outer cladding 22 is made of unsaturated polyester resin .

[0060] The feather stalk with leather core structure is manufactured by resin pouring process, specifically:

[0061] In the first step, the continuous filament glass fiber is selected as the reinforcing material, the unsaturated polyester resin is selected as the matrix material, and the fiber-reinforced composite material wire is produced by the pultrusion process, and the wire is cut into a suitable length to be used as the inner core 21 .

[0062] In the second step, choose a grammage of 30g / m 2 The polyester spinning cloth of left and right is cut into applicable shape and size, and is processed as pinnae 12 through hot edge processing...

Embodiment 3

[0068] A kind of artificial feather of the present invention, as Figure 4 As shown, its pinna 12 is made of a polyester diaphragm, and the feather stem 11 is a leather-wrapped structure. The inner core 21 is made of a reinforced composite material mixed with glass fibers and spinning fibers, and the outer cladding 22 is made of nylon. Made, also called PA plastics, this artificial feather has a reinforcing member 13 of the membrane pressing structure that is positioned at feather stalk head position.

[0069] The manufacturing process of this artificial feather is basically the same as in Embodiment 1, but the reinforcement member 13 is slightly different, specifically:

[0070] ...

[0071] The sixth step is to cut a piece of lightweight plastic film with a size of about 14mm×8mm, and press this film on the head of the feather stalk 11. The film and pinna will cover the head of the feather stalk, and glue the film , pinna and pinnae are bonded firmly, and the plastic film ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com