Pneumatic screening machine

A screening machine and pneumatic technology, applied in the direction of solid separation, separating solids from solids with airflow, chemical instruments and methods, etc., can solve problems such as large power consumption, environmental pollution, cost increase, etc.

Inactive Publication Date: 2009-09-16

张士友 +1

View PDF0 Cites 14 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The output ratio of this water separation method adopted by traditional mining enterprises is not satisfactory, and it consumes a lot of electricity, water, and serious environmental pollution. Due to repeated operations by operators, the corresponding product cost increases, work efficiency decreases, and other disadvantages. factor

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

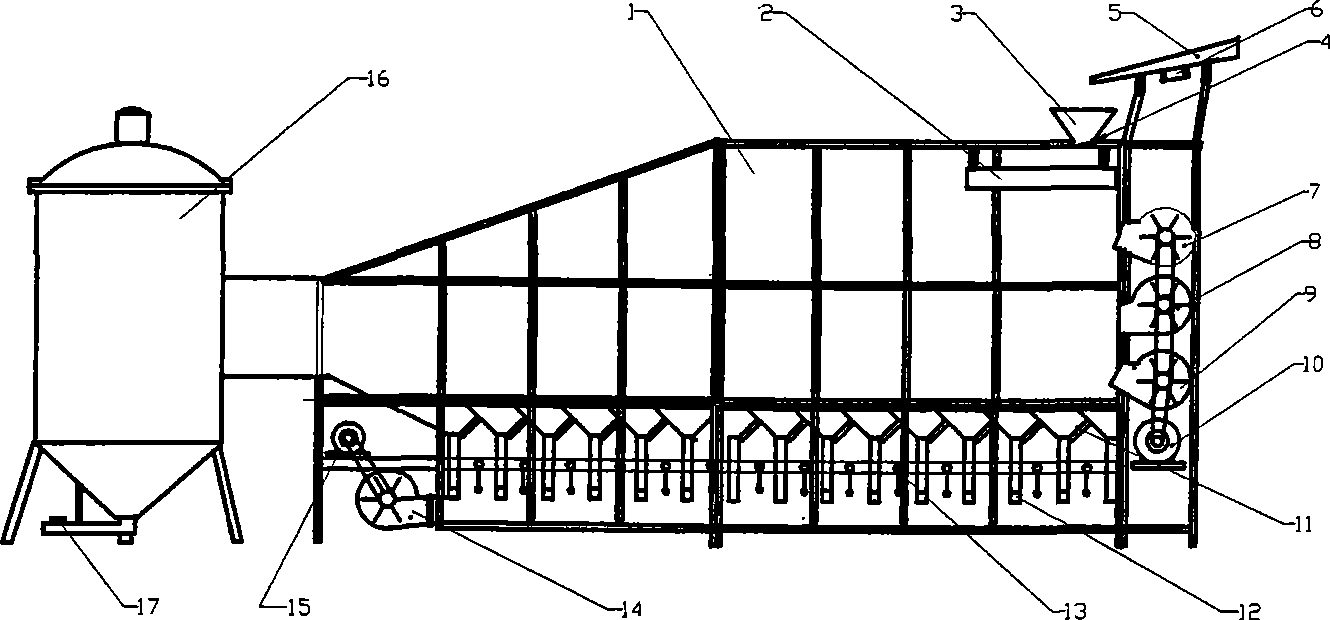

[0008] figure 1 Patent Structure Diagram of the Invention

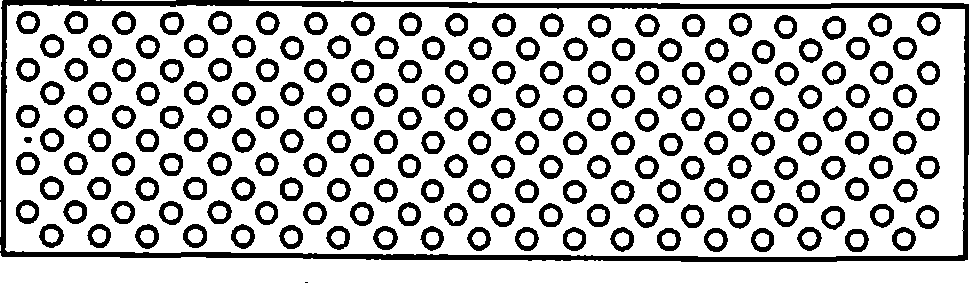

[0009] figure 2 Parallel taper duct structure

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention relates to mine beneficiation equipment, in particular to mine winnowing equipment. The design adopts a pneumatic structure; the high fall leads the mineral powder to disperse sufficiently; the mineral powder disperses and falls uniformly by a vibration screen; an axial-flow fan blows the mineral powder to a certain distance; as the mineral powder contains various matter elements with different densities, the distances of the blown matters are different, and the linear speed of the movement of the blown matters are also different due to different density. Along the blown distances, due to different densities of the mineral powders, various matter elements with different blown distances and different linear speeds are dropped in different recovery troughs at different distances, thus achieving the separation effect of various matter elements of the mineral powder.

Description

technical field [0001] The patent of the present invention relates to a kind of mine beneficiation equipment, especially a kind of mine winnowing equipment. For the screening of mineral powder, it brings a new type of environmentally friendly mineral powder screening equipment that is simple and feasible, saves electricity and water, improves output rate. Background technique [0002] At present, most of the mineral powder screening equipment used by known mining enterprises are traditional water separation screening equipment, also known as water separation method, water separation method screening equipment such as rolling launder, rotating launder, vertical large helix angle launder, vibration Chutes and more. No matter how the screening structure of the equipment is changed, its basic design mechanism still requires a large amount of water and electric energy to screen out various metal elements in the ore powder through chemical reactions. If the ore powder contains m...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): B07B11/00B07B11/02B07B9/00B07B4/02

Inventor 张士友刘连志

Owner 张士友

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com