Container with automatic switch valve

An automatic switch and valve technology, applied in the direction of soft tubular containers, containers, rigid containers, etc., can solve problems such as difficult to cooperate, difficult to comply with environmental protection, resource recovery, content leakage, etc., to save production procedures and costs, The effect of eliminating manual alignment assembly and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] In order to disclose the technical scheme used in the present invention, the purpose of the invention and the effects achieved therein more completely and clearly, a more detailed description will be given below in conjunction with the accompanying drawings.

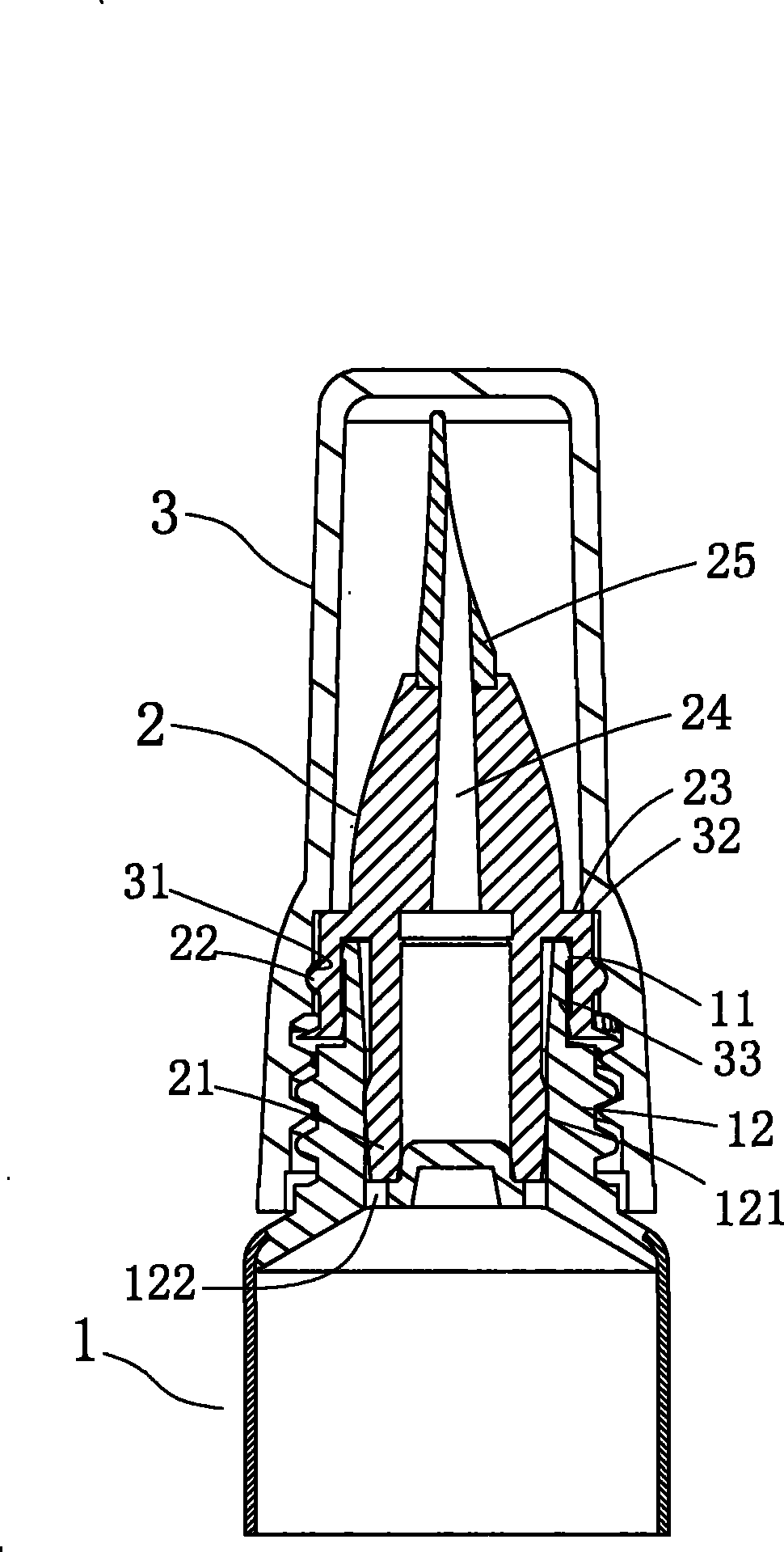

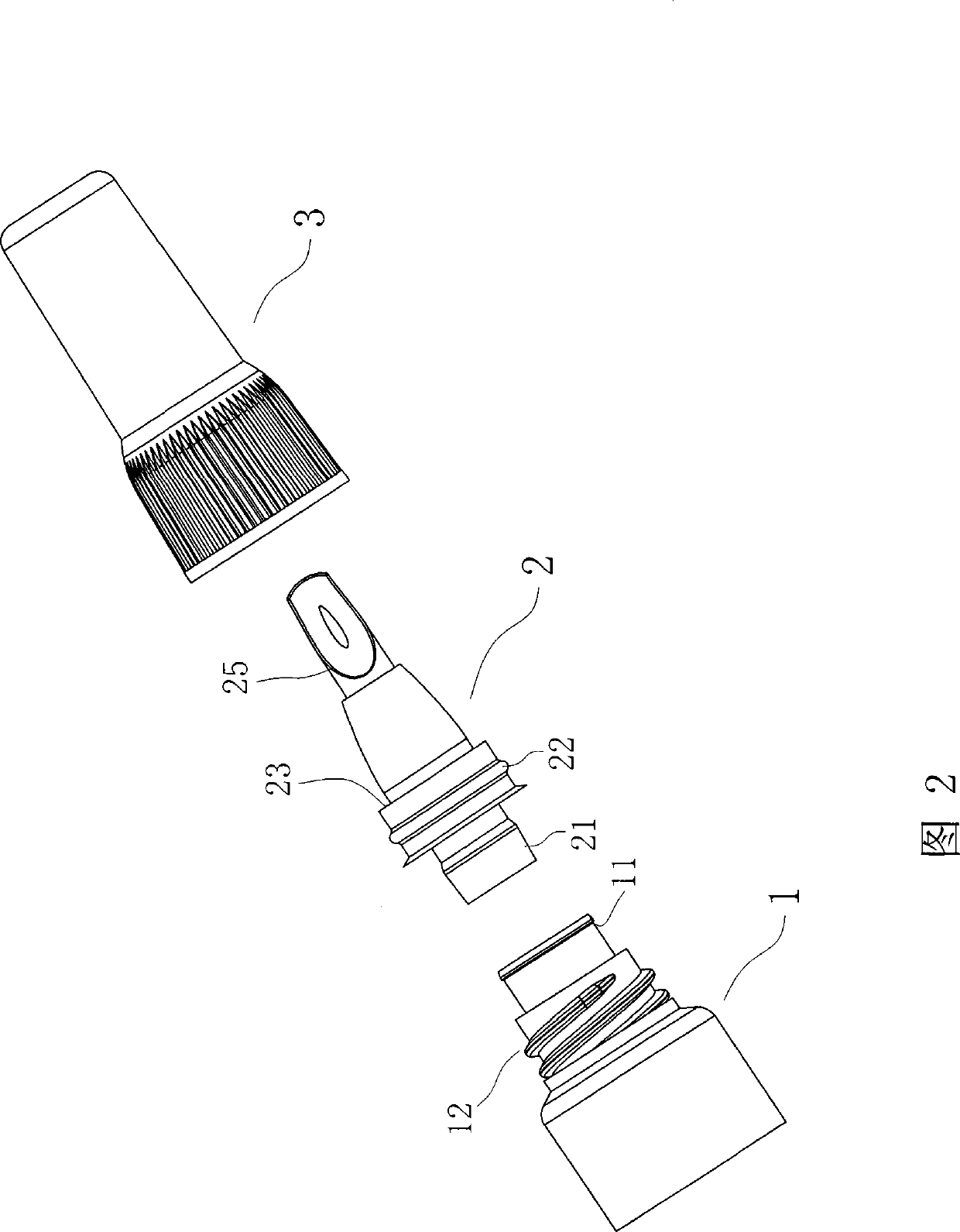

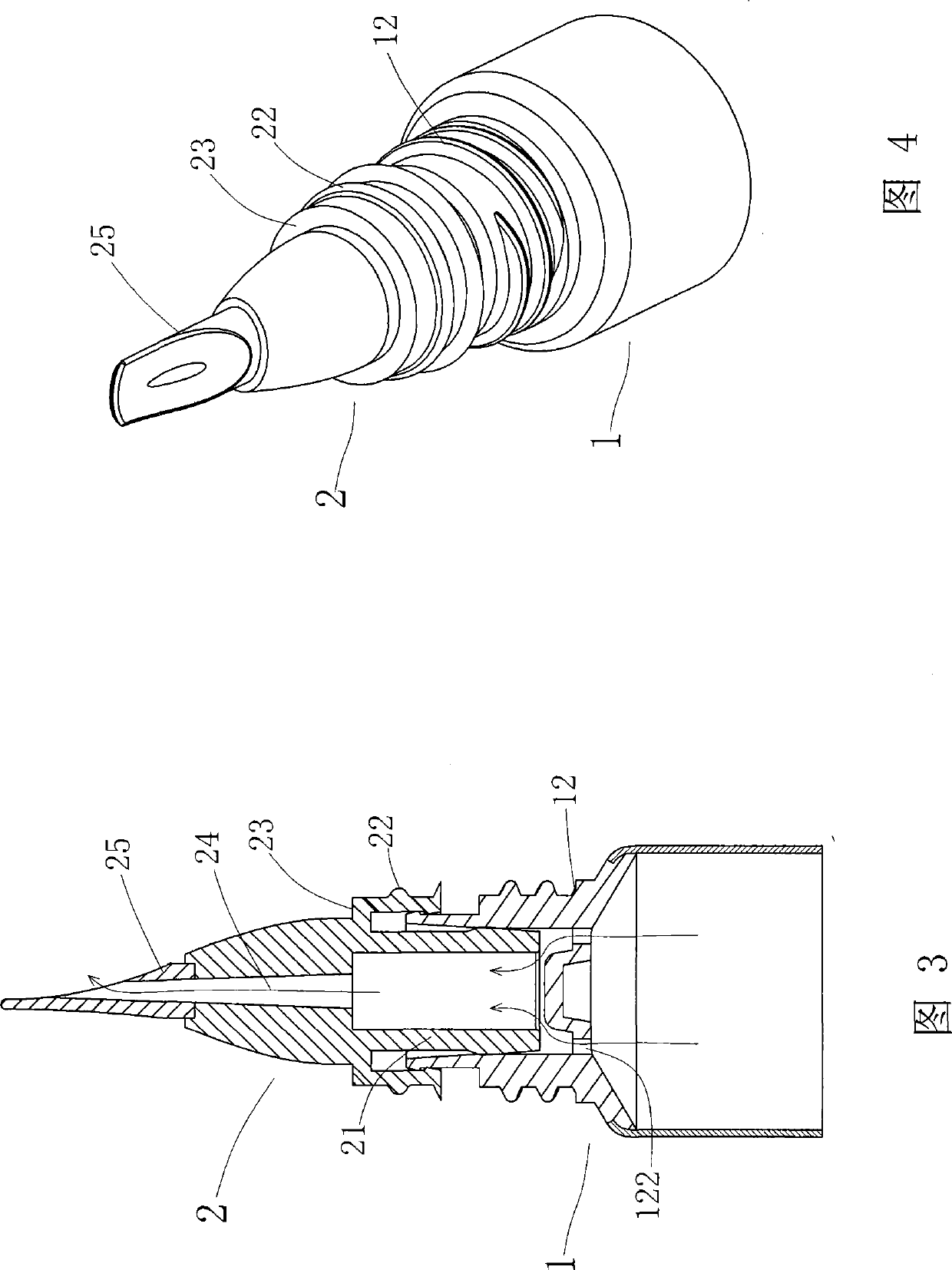

[0044] refer to figure 1 -4. The container with automatic switch valve includes a container body 1, an applicator 2 and a cover 3, wherein:

[0045] The inner wall of the head 12 of the container body 1 is directly formed into a valve seat 121, and several liquid outlets 122 are arranged horizontally at the bottom end of the valve seat 121 for the contents of the container body 1 to flow out. The thread is used to lock the cover body 3, and a card edge 11 is protruded at the top of the outer wall of the head 12, which can cooperate with the flange 33 on the mating surface of the applicator 2 to stop the application when the cover body 3 pulls the applicator 2 The device 2 is unlikely to be pulled out of the hea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com