Composition prediction device of sinter product and method thereof

A technology for ore finished products and finished products, which is applied in the field of component forecasting devices for sintered ore products, can solve problems such as high defective rate, finished products cannot meet the process requirements, and cannot obtain product composition information in time, so as to reduce time delay and delay The effect of product rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

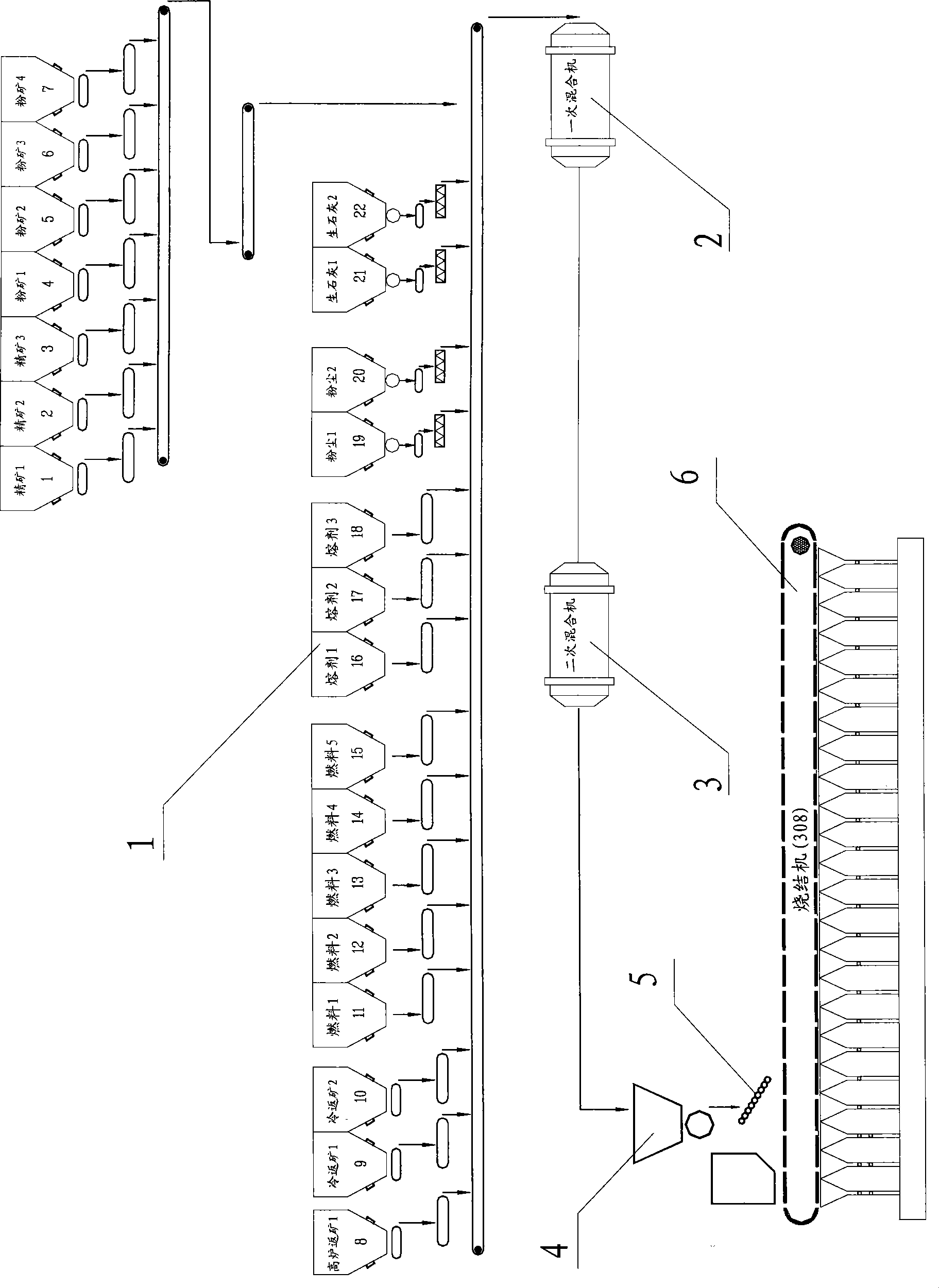

[0047] In order to make the above objects, features and advantages of the present invention more comprehensible, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

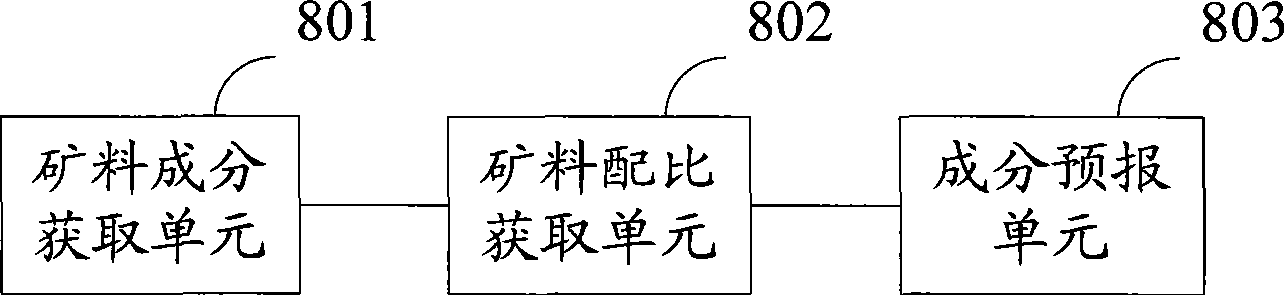

[0048] The component forecasting device of the finished sintered ore product according to the present invention is set at the first assembly point, by obtaining the ratio of each mineral material in the mixed material falling on the mixing belt, and combining the percentages of various components in each mineral material The predicted value of the percentage content of various components in the finished sintered ore product is obtained by calculation.

[0049] refer to figure 2 , is the structural diagram of the component prediction device for the finished sintered ore product according to the first embodiment of the present invention.

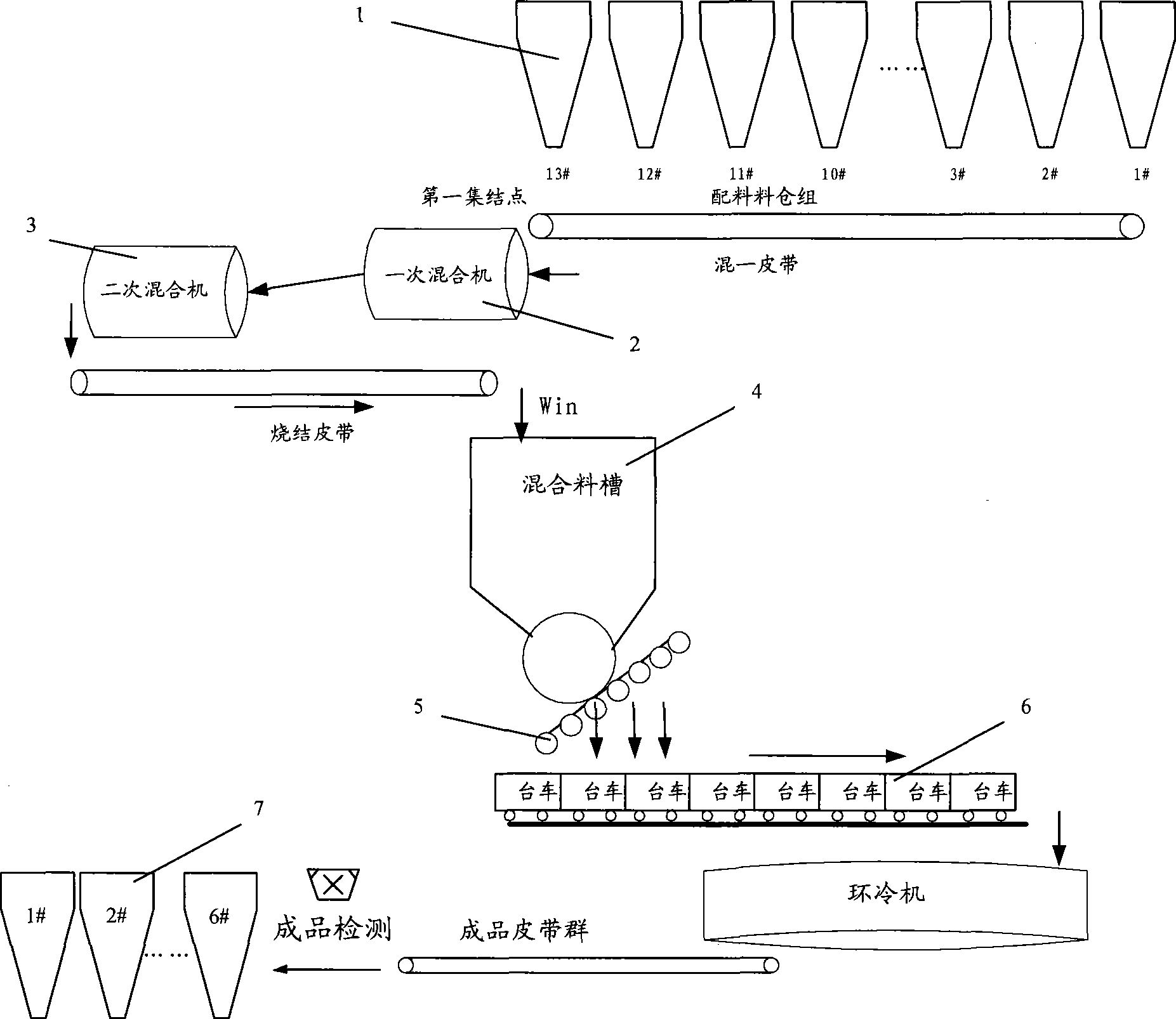

[0050] see figure 1, set the junction of the mixing belt and the primary mixer 2 as the fir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com