Fluorine rubber material and preparation method thereof

A fluororubber and rubber-based technology, applied in the field of fluororubber materials and their preparation, can solve problems such as the inability of rubber to be used for a long time, and achieve the effects of reducing compression deformation, small volume change and increasing stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

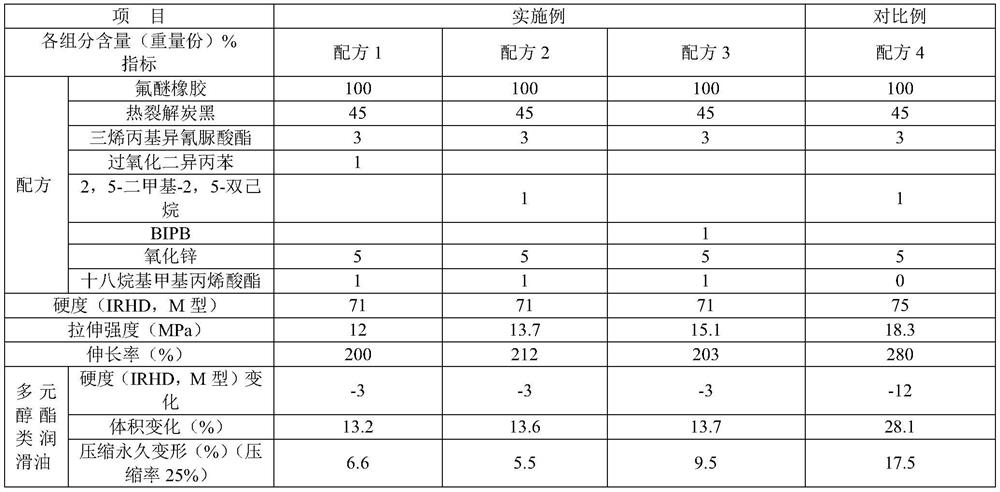

[0019] Aiming at the problem that the existing rubber cannot be used for a long time in the polyol ester lubricating oil, the invention proposes a fluororubber material and a preparation method thereof. The raw materials of the fluororubber material include the following components, in parts by mass: 90-110 parts of rubber base material, 40-50 parts of reinforcing agent, 2-4 parts of vulcanizing agent, 1-2 parts of vulcanization auxiliary, acid absorption 5-10 parts of vulcanization accelerator, 1-2 parts of vulcanization accelerator.

[0020] The preparation method of the above-mentioned fluororubber material, comprises the following steps:

[0021] (1) First, adjust the temperature of the twin rolls of the twin-roll rubber mill to 25-80°C, the feeding amount at one time is less than 10kg, the roll distance is 5-10mm, and the roll speed ratio is 1:1-1.5, and then the rubber base material is placed on the double-roller. Thinly pass 5 to 15 times in the rubber mixing machine t...

Embodiment 1

[0036] (1) First, adjust the temperature of the twin rolls of the twin-roll rubber mill to 50°C, adopt a roll distance of 5mm, a feeding amount of 5kg at a time, and a roll speed ratio of 1:1.25. According to the formula 1 in Table 1, the FLT-Ⅰ type fluorine 100 parts of ether rubber base material were thinly passed 10 times in a two-roll rubber mixing machine to form a uniform roll material, adjust the roll distance to keep a small amount of accumulated rubber, and add other auxiliary materials in turn: 45 parts of pyrolysis carbon black, triallyl 3 parts of isocyanurate, 1 part of dicumyl peroxide, 5 parts of zinc oxide, and 1 part of octadecyl methacrylate; The materials and auxiliary materials are mixed evenly, and the mixing process should be as fast as possible to prevent over-refining and sticking. The mixture is repeatedly put into and passed through the double rolls of the rubber mixing machine. During the repeated mixing process, the distance between the double rolls...

Embodiment 2

[0039](1) First, adjust the temperature of the two rollers of the two-roll rubber mill to 50°C, adopt a 5mm roller distance, a feeding amount of 5kg at a time, and a roller speed ratio of 1:1.25. According to the formula 2 in Table 1, the FLT-I type fluorine 100 parts of ether rubber base material were thinly passed 10 times in a two-roll rubber mixing machine to form a uniform roll material, adjust the roll distance to keep a small amount of accumulated rubber, and add other auxiliary materials in turn: 45 parts of pyrolysis carbon black, triallyl 3 parts of isocyanurate, 1 part of 2,5-dimethyl-2,5-dihexane, 5 parts of zinc oxide, 1 part of octadecyl methacrylate; after the feeding is completed, thin pass 10 times , beat the triangle bag 15 times to make the base material and auxiliary material mix evenly, and the mixing process should be as fast as possible to prevent over-refining and sticking. The mixture is repeatedly put into and passed through the double rolls of the ru...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com