Production device and technique used both for hot galvanizing and continuous annealing

A hot-dip galvanizing and annealing technology, which is applied in hot-dip galvanizing process, metal material coating process, coating, etc., can solve problems such as single function, and achieve the effect of improving enterprise efficiency and improving the ability to adapt to the market

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

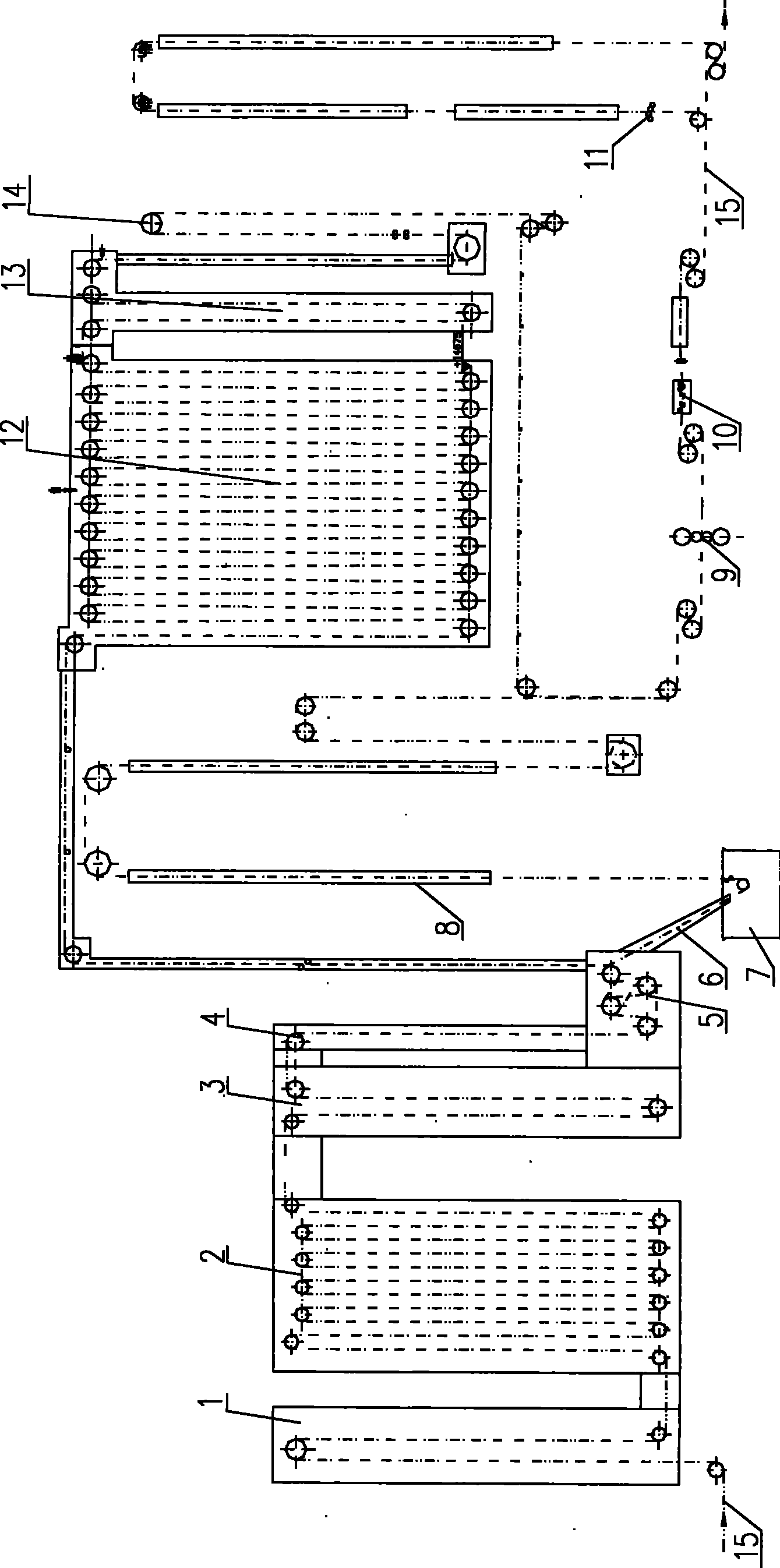

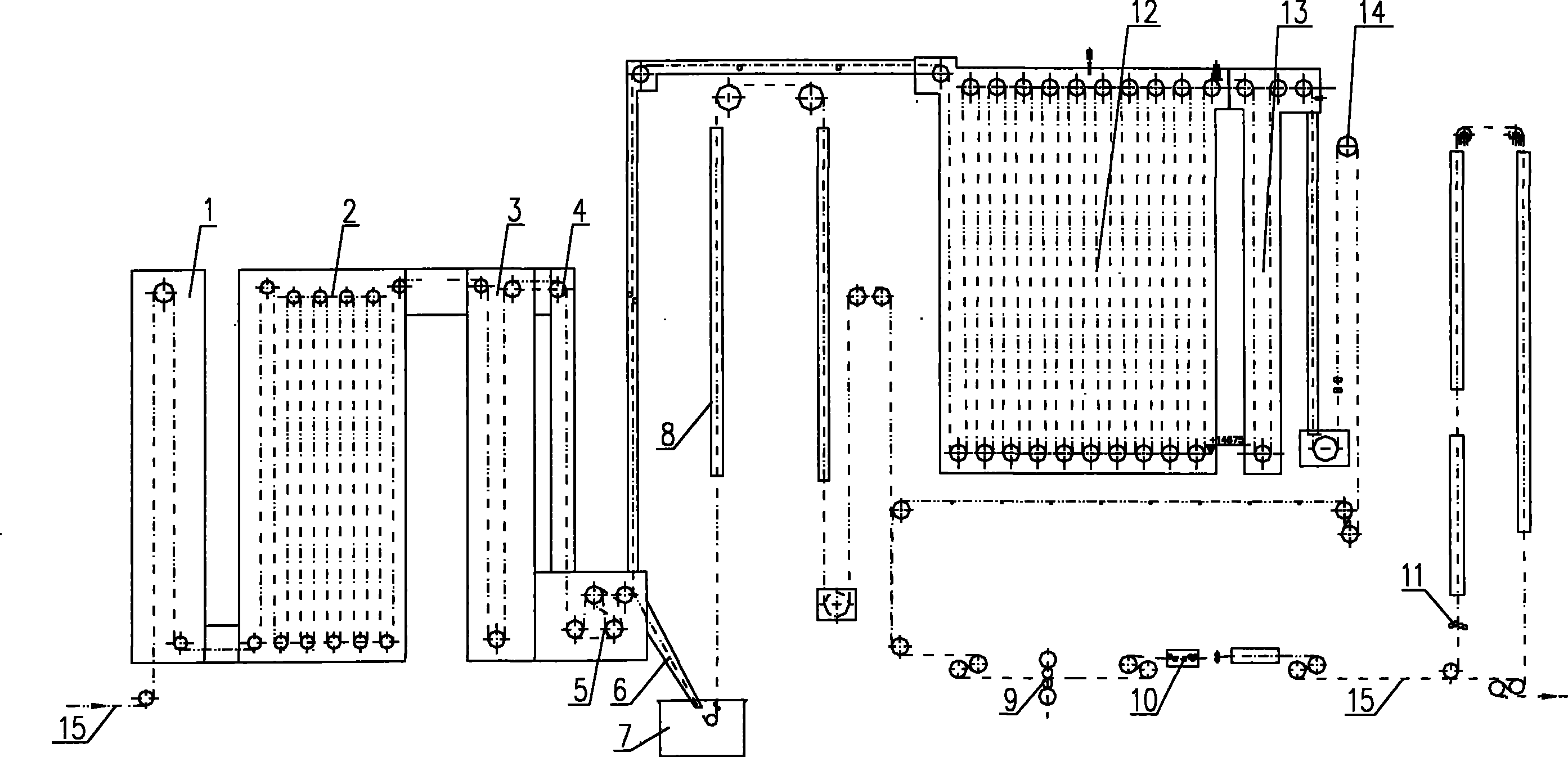

[0009] The specific implementation of the present invention will be further described below in conjunction with the accompanying drawings:

[0010] The present invention is successively installed with preheating section 1, heating section and soaking section 2, cooling section 3, equalizing section 4, heat-stretching roll zone 5, furnace nose section 6, zinc pot 7, and cooling section after plating. 8. Finishing machine 9, tension straightening machine 10, roller coating system 11 and strip conveying equipment 14. At the same time, an over-aging section 12 and a secondary cooling section 13 are installed in parallel in the heat stretching roll zone 5.

[0011] The process method of the present invention is briefly described as follows:

[0012] When producing hot-dip galvanized products, the strip steel 15 enters the preheating section 1, the heating section and the soaking section 2, the cooling section 3, the equalizing section 4, and the heat-stretching roll zone 5 of the continuo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com