High-strength electric power-transmitting iron tower

A transmission tower, high-strength technology, applied in the field of transmission towers, can solve the problems of increasing the strength and economy of the whole tower, and achieve the effect of good strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

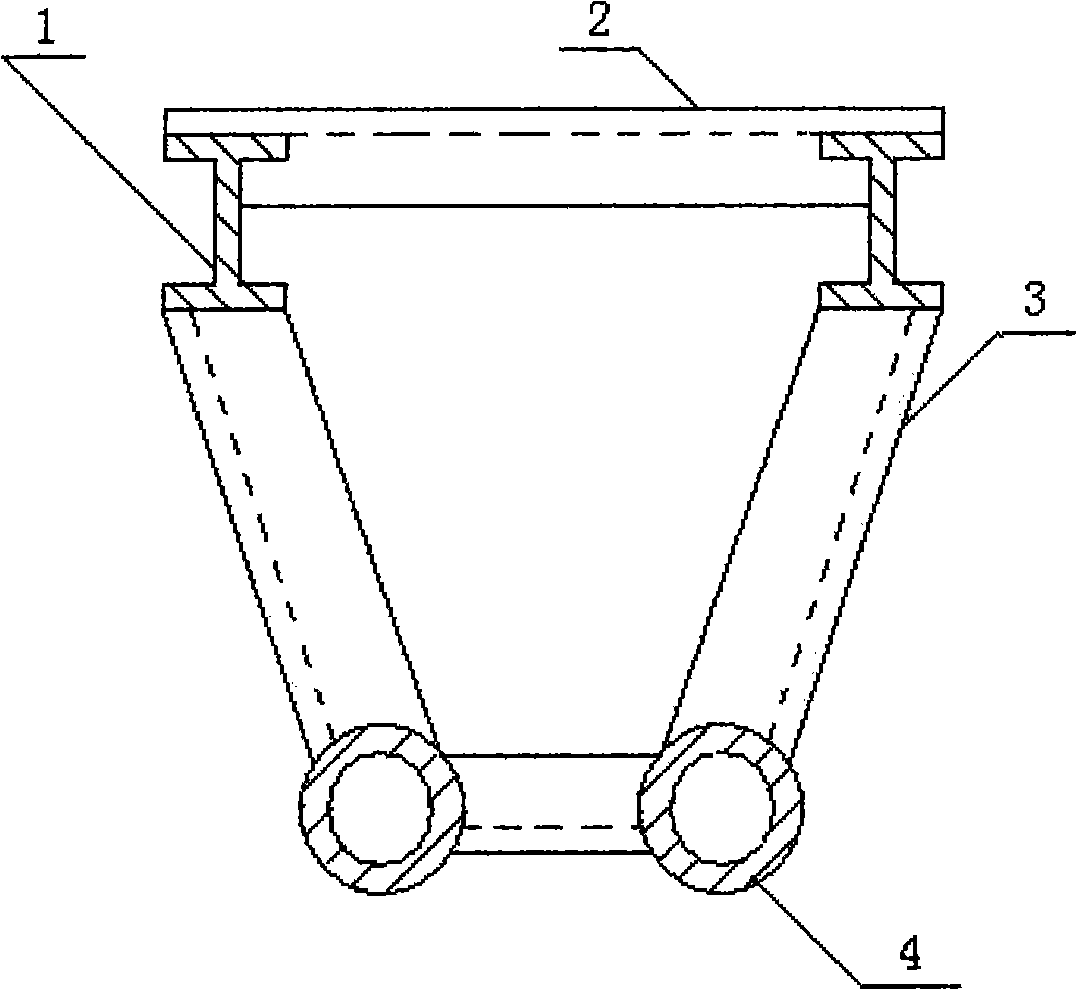

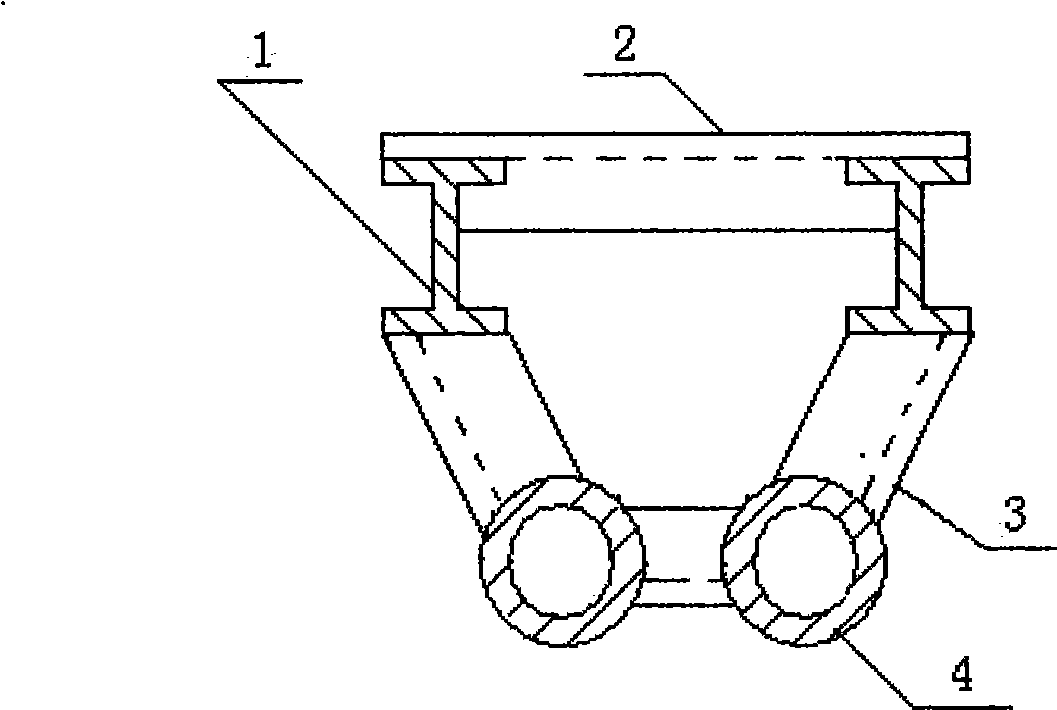

[0021] The structural details and specific implementation methods of the high-strength power transmission tower of the present invention will be described below in conjunction with the accompanying drawings.

[0022] Such as figure 1 As shown, the I-shaped steel (1), the cross brace (2), the diagonal brace (3) and the steel pipe (4) are welded to form the trapezoidal section tower body of the transmission tower, and the trapezoidal lower bottom column of the tower body is made of I-shaped steel (1) make, and the upper base column of tower body cross-section trapezoid is made with steel pipe (4), and the cross strut (2), diagonal strut (3) of tower body are made with angle steel. The direction of the maximum bending capacity of the I-beam (1) at the column part of the tower body is the same as the direction of the height of the trapezoidal section of the tower body. An appropriate amount of diagonal stays can be arranged in the vertical direction and the horizontal direction ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com