Post-treatment waste gas recycling high-temperature blower

An exhaust gas circulation and high temperature technology, applied in mechanical equipment, machines/engines, liquid fuel engines, etc., can solve problems such as short service life and unsatisfactory work performance, and achieve long service life, reasonable structure and good work performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

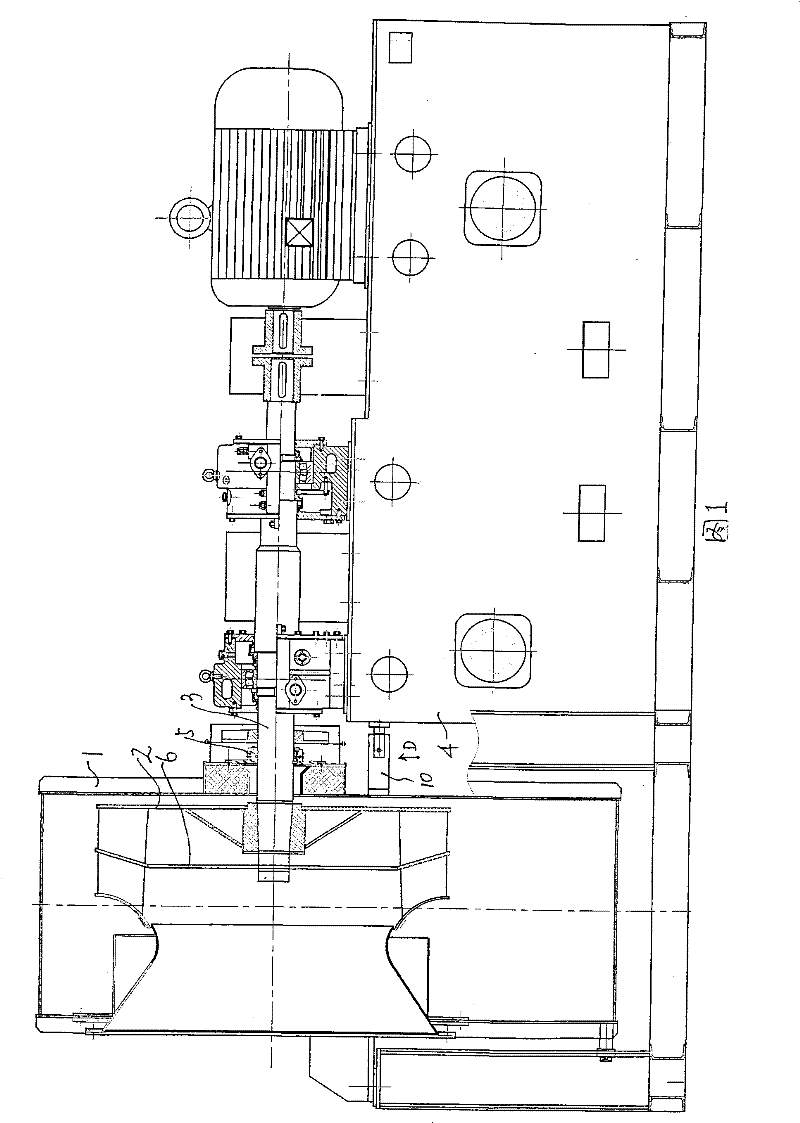

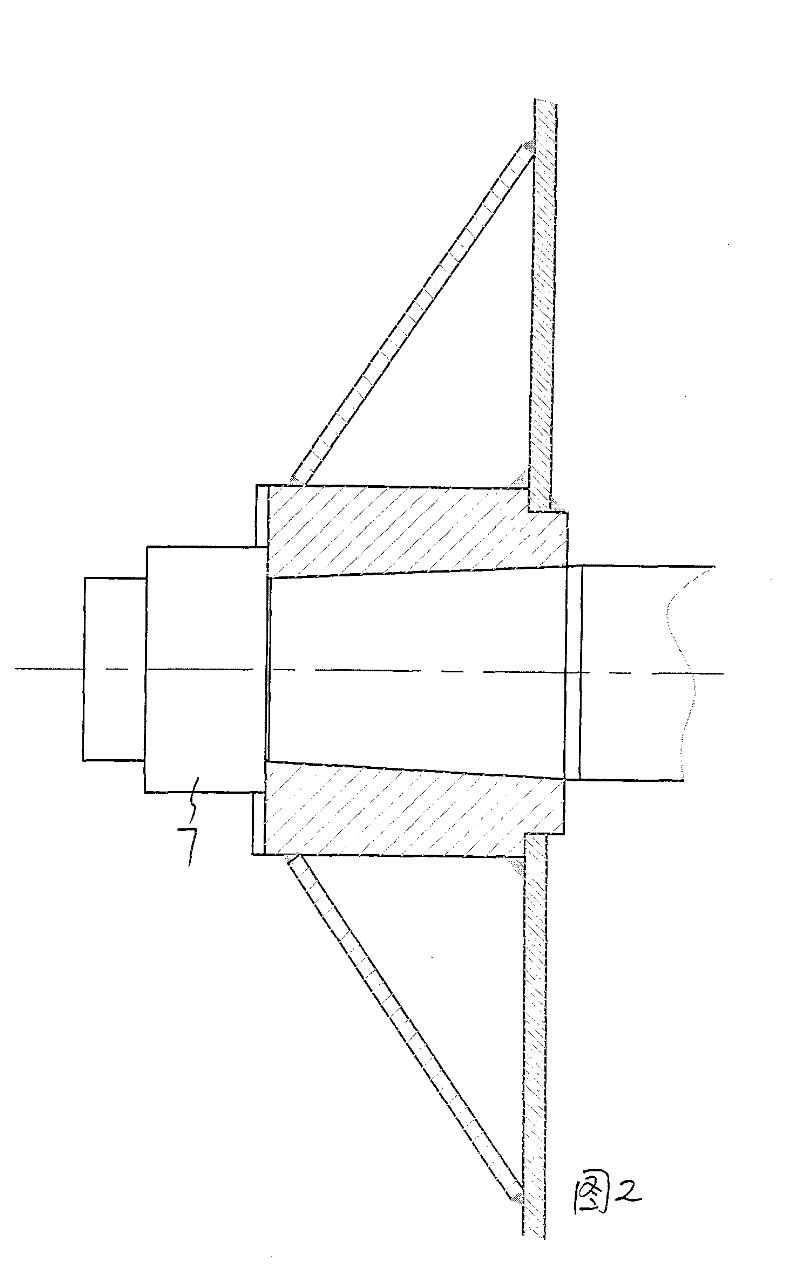

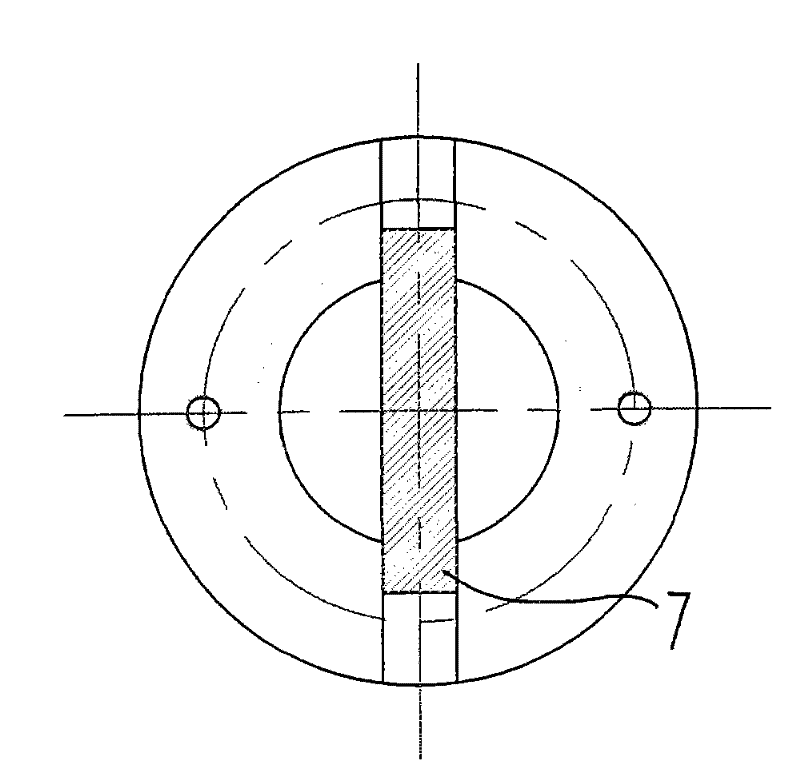

[0015] A post-processing exhaust gas circulation high-temperature fan, including a casing 1, an impeller 2, a main shaft 3, a pedestal 4, and a main shaft seal 5. A sub-front disc 6 is arranged between the front disc and the rear disc of the impeller, and a conical surface is used for the assembly of the main shaft and the hub. Combining, make a groove on the end face of the hub, and use the wedge key 7 to lock the radial hole of the main shaft and the end face groove of the hub.

[0016] The main shaft seal adopts the method of labyrinth and carbon ring seal 8, and is equipped with nitrogen seal 9. The nitrogen seal is arranged between the front and rear two labyrinth plus carbon ring seals. The pedestal 4 adopts an integral pedestal. A casing expansion guiding device 10 is arranged between the rear end of the casing and the pedestal.

[0017] The casing expansion guide device includes a flat plate 11 vertically connected to the casing 1, a U-shaped groove body 12 connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com