Microflow distribution device, manufacturing method and application thereof

A dispensing device and microfluidic technology, used in chemical instruments and methods, optomechanical equipment, testing pharmaceutical preparations, etc., can solve the problems of expensive equipment and complicated operation methods.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

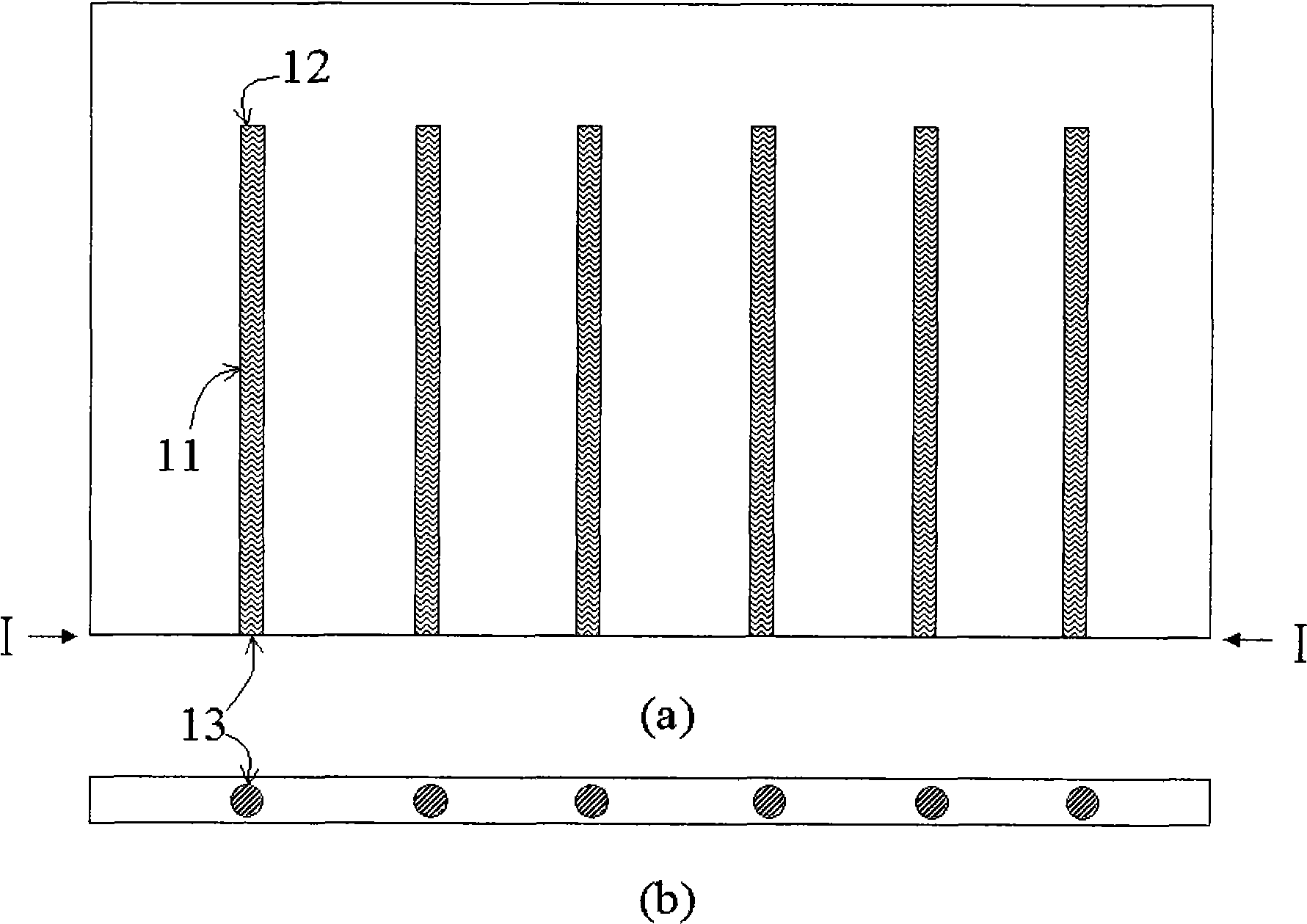

[0062] The following will refer to the attached figure 1 The structure of the microfluidic distribution chip with multiple parallel microfluidic channels is described in detail. figure 1 (a) Front view of the microfluidic distribution chip, figure 1 (b) is a cross-sectional view along the I-I direction, 11 is the microfluidic channel, 12 is the inlet of the microfluidic channel, and 13 is the outlet of the microfluidic channel.

Embodiment 2

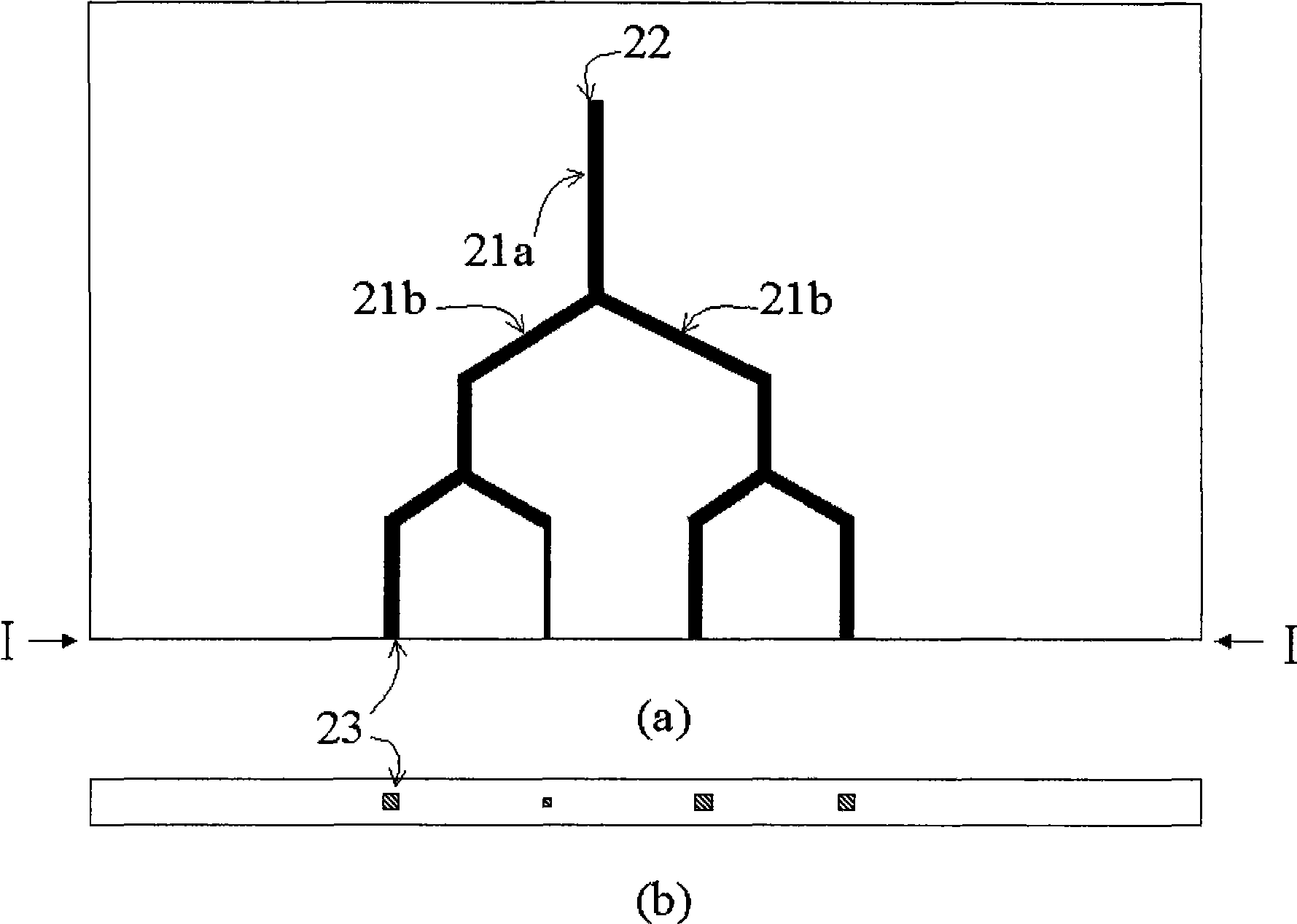

[0064] The following will refer to the attached figure 2 The structure of a microfluidic distributing chip with a group of microfluidic channel trees formed by a root microfluidic channel branching multiple times is described in detail. figure 2 (a) Front view of the microfluidic distribution chip, figure 2 (b) is a cross-sectional view along the I-I direction, 21a is the root microfluidic channel, 21b is a new microfluidic channel formed by the root microfluidic channel through a bifurcation, 22 is the entrance of the microfluidic channel, and 23 is the microfluidic channel outlet of the flow channel. Two new microfluidic channels 21b formed by bifurcating the root microfluidic channel together with the root microfluidic channel 21a form a Y shape.

Embodiment 3

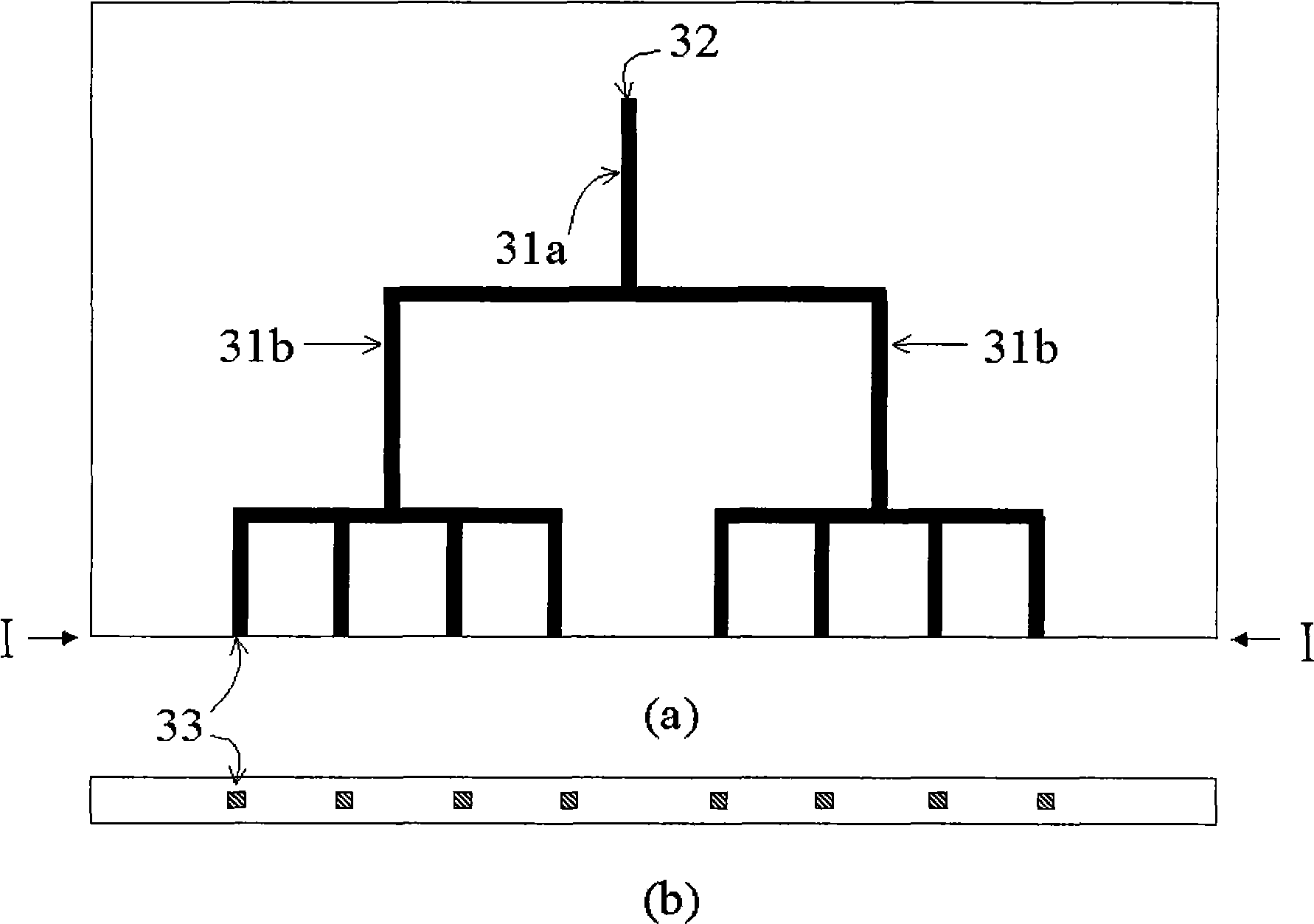

[0066] The following will refer to the attached image 3 The structure of another microfluidic distribution chip with a group of microfluidic channel trees is described in detail. image 3 (a) Front view of the microfluidic distribution chip, image 3 (b) is a cross-sectional view along the I-I direction, 31a is the root microfluidic channel, 31b is a new microfluidic channel formed by the root microfluidic channel through a bifurcation, 32 is the entrance of the microfluidic channel, and 33 is the microfluidic channel outlet of the flow channel. Two new microfluidic channels 31b formed by bifurcating the root microfluidic channel together with the root microfluidic channel 31a form a letter T shape.

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com