Method in a continuously operating unwind for a fibre web, in particular for a paper or board web, and a continuously operating unwind for a fibre web, in particular for a paper or board web

A fiber web and equipment technology, applied in the field of continuous operation uncoiling equipment, can solve the problems of increasing web breakage and deterioration of adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

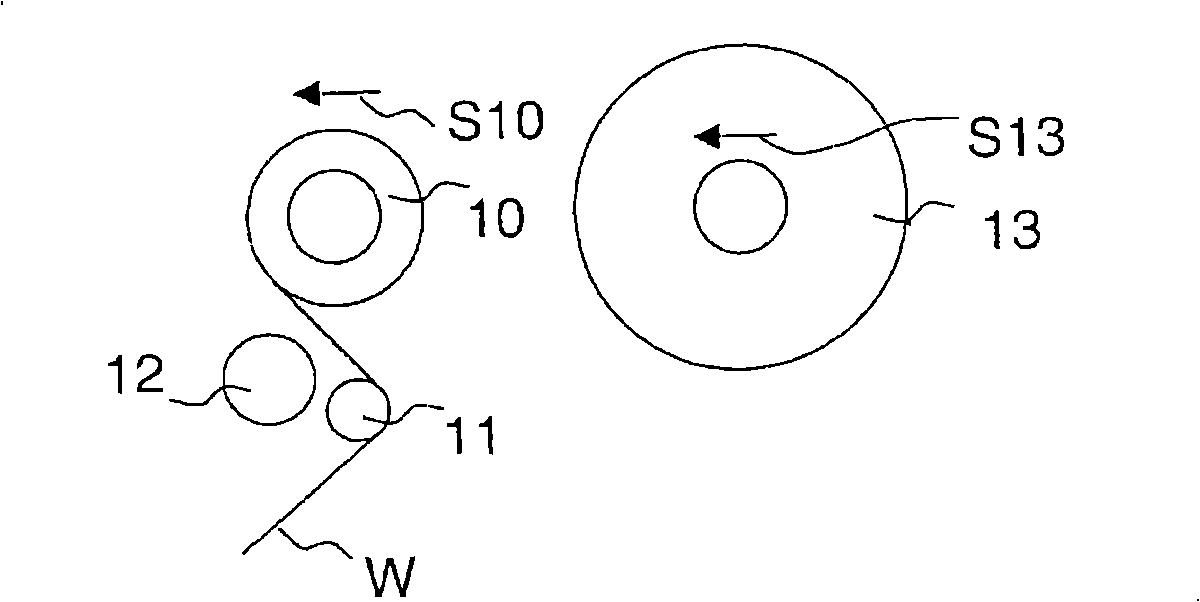

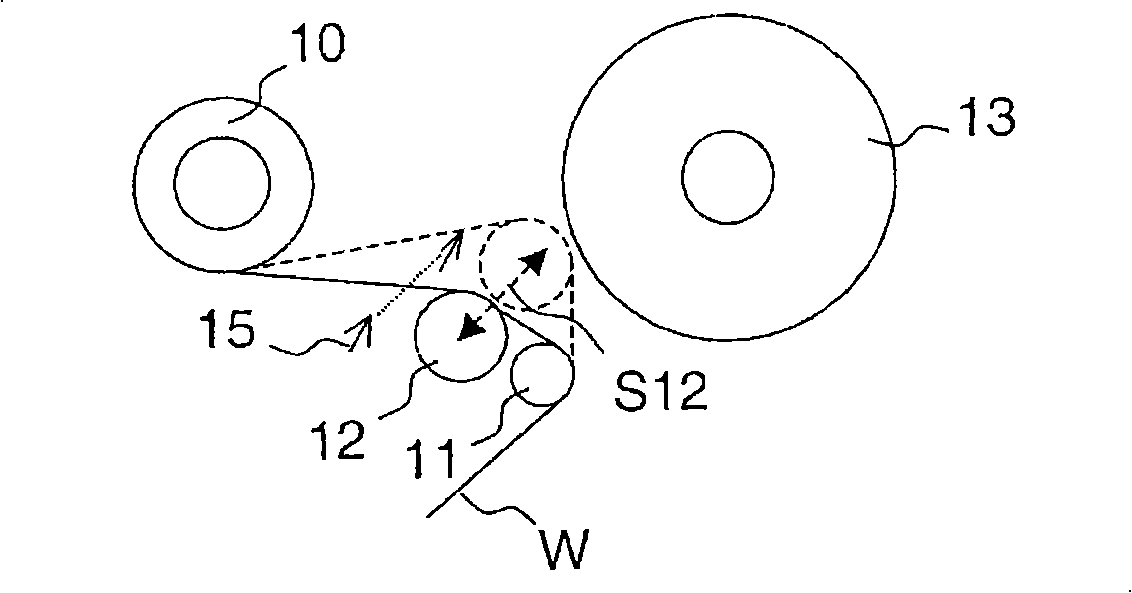

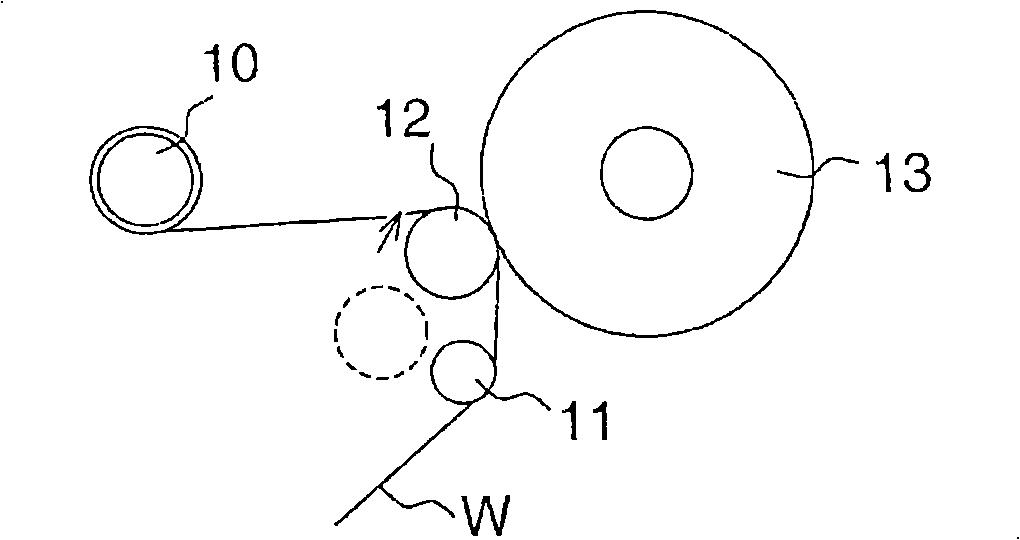

[0025] In the figures, the web being wound is indicated by the reference W; the splicing roll is indicated by the reference 12; the web guide roll of the splicing device is indicated by the reference 11; the new machine roll is indicated by the reference 13 indicates that after splicing it becomes uncoiled from said new machine reel; the old machine reel is indicated by reference numeral 10 from which the web was uncoiled before splicing. The cutting blade of the cutting device of the web W is indicated by reference numeral 15 . In splicing, the old web is brought close to the face of the new machine roll 13 and the web is pressed against the face of the machine roll 13 using the splicing roll 12 . The old web is cut with a cutting knife 15 . The guard 16 prevents shredded paper from entering the splicing-related nip between the splicing roll 12 and the new machine roll 13 , ie the splicing nip. In addition to the splicing roll 12, the splicing device thus comprises at least...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com