Combined die cutting roller

A die-cutting roller and combined technology, which is applied in metal processing and other directions, achieves the effects of low scrap cost, convenient disassembly, and convenient maintenance and operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

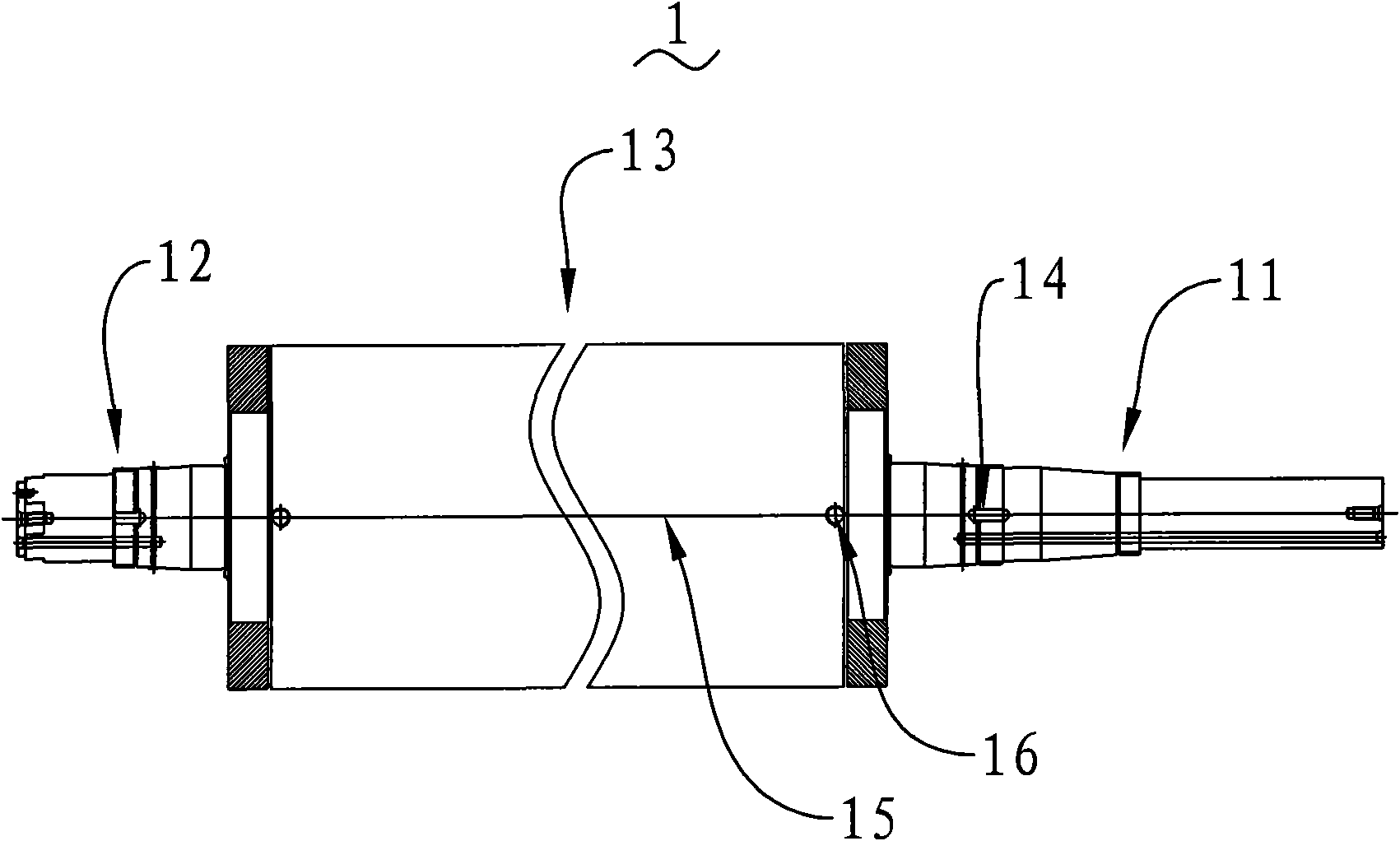

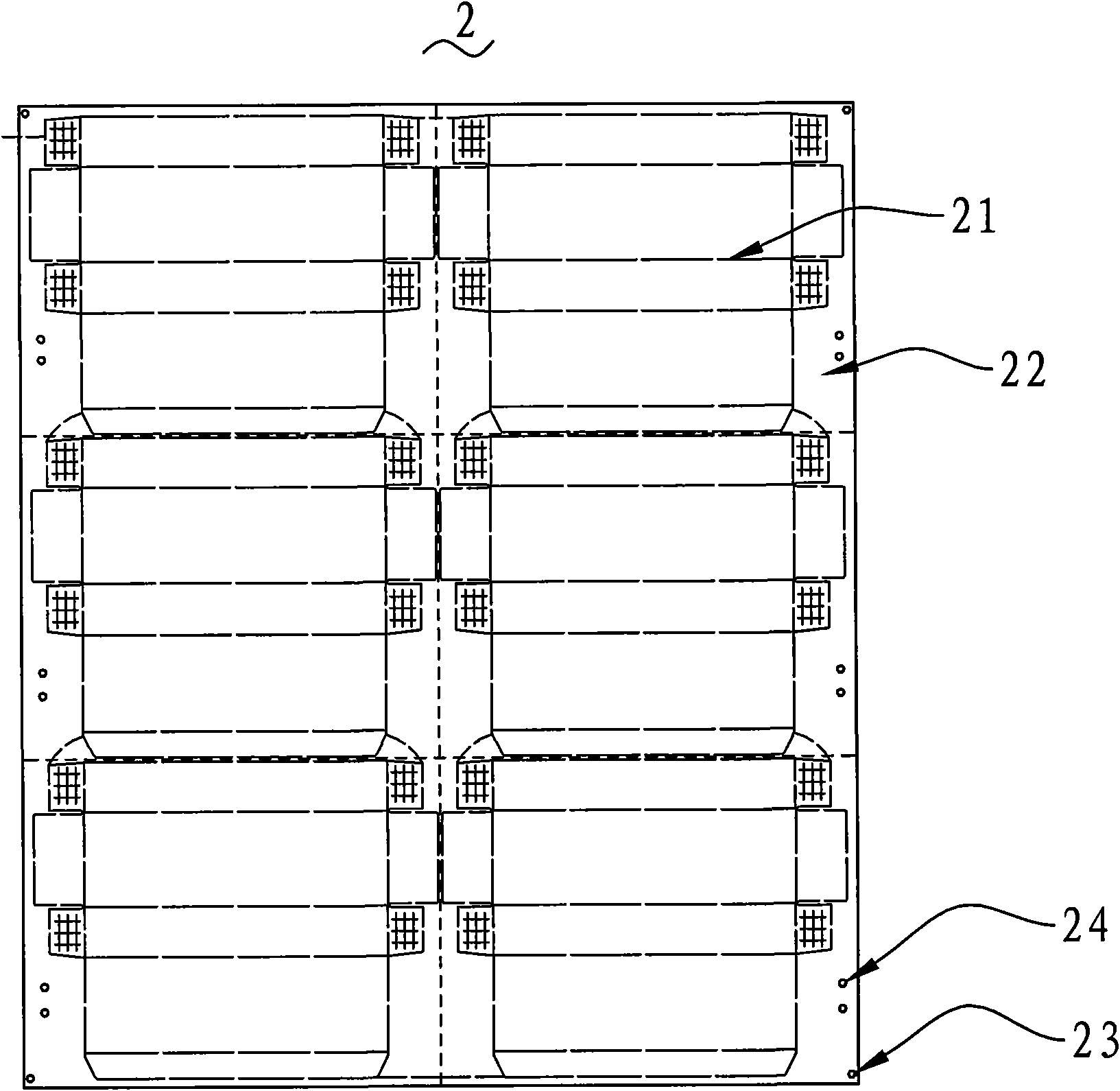

[0019] Such as figure 1 and figure 2 As shown, a combined die-cutting roller, which includes a roller entity 1 and a die-cutting part movably connected to the roller entity 1; the die-cutting part is a sheet-shaped knife skin 2 for die-cutting , The knife skin 2 is provided with a knife edge 21 with a certain shape and arrangement. According to the size of the die-cutting object and the die-cutting requirements, the roller body 1 and the knife skin 2 are selected, and the knife skin 2 must be installed on the roller body. After the die-cutting roller is installed on the die-cutting device, the die-cutting operation is carried out according to the production requirements. When the blade 21 is damaged or the blade 21 is deformed, it is possible to stop for a short time to replace or maintain the blade skin 2, but it must be stopped for a long ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com