Besmirch resistant water-containing coating composition

A composition, stain-resistant technology, applied in the field of polymer chemistry, which can solve problems such as low stain resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

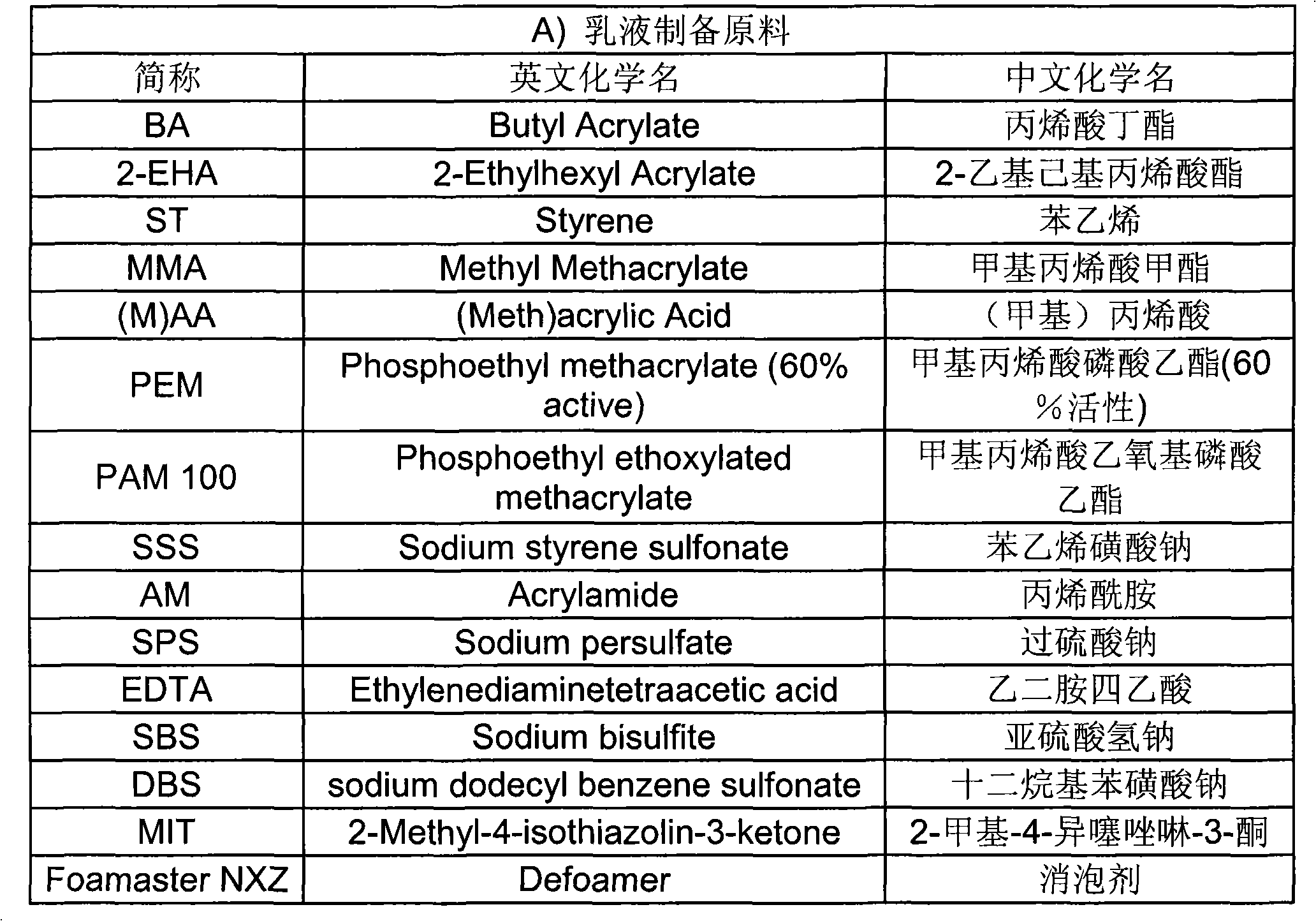

[0075] Preparation of Aqueous Emulsion Polymers

[0076] Lotion 1

[0077] The components of the prepared monomer emulsion were: 922g BA, 579g ST, 30.6g AA, 5.6g SSS, 438g deionized water and 64.26g 22.5wt% DBS aqueous solution, stirred and emulsified. Next, 14.11 g of 22.5 wt % DBS aqueous solution and 569 g of deionized water were added to a 5-liter multi-neck bottle equipped with mechanical stirring. The contents of the flask were heated to 90°C under a nitrogen atmosphere. To the contents of the stirred flask were added 52.4 g of monomer emulsion, 1.91 g of Na dissolved in 35.4 g of DI water 2 CO 3 , 0.035g of ferrous sulfate and 0.019g of EDTA dissolved in 15.6g of deionized water, and then 5.35g of SPS dissolved in 15.6g of deionized water was added. The remaining monomer emulsion and 2.2 g SPS dissolved in 60 g DI water and 2.34 g SBS dissolved in 60 g deionized water were added to the flask over 180 minutes. The reaction temperature was maintained at 87°C. Next, ...

Embodiment 2

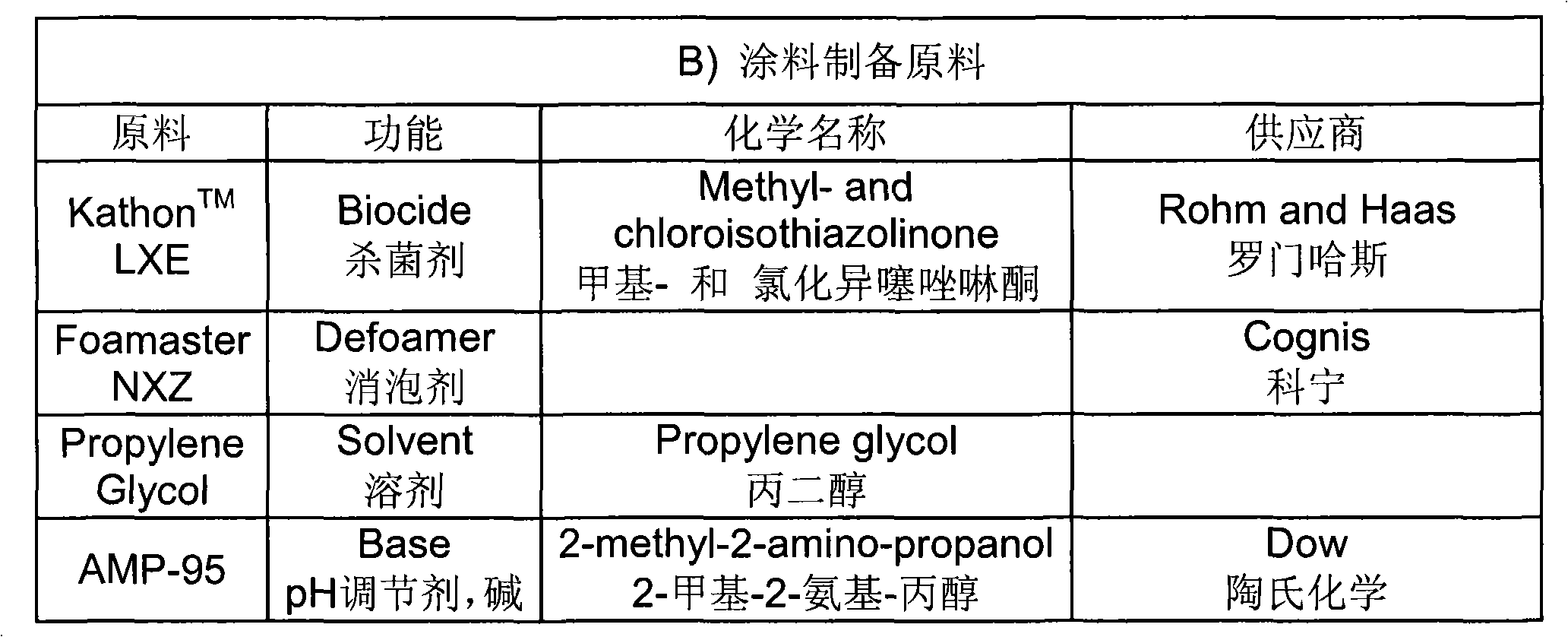

[0093] Preparation of stain resistant aqueous coating composition

[0094] Paint 1

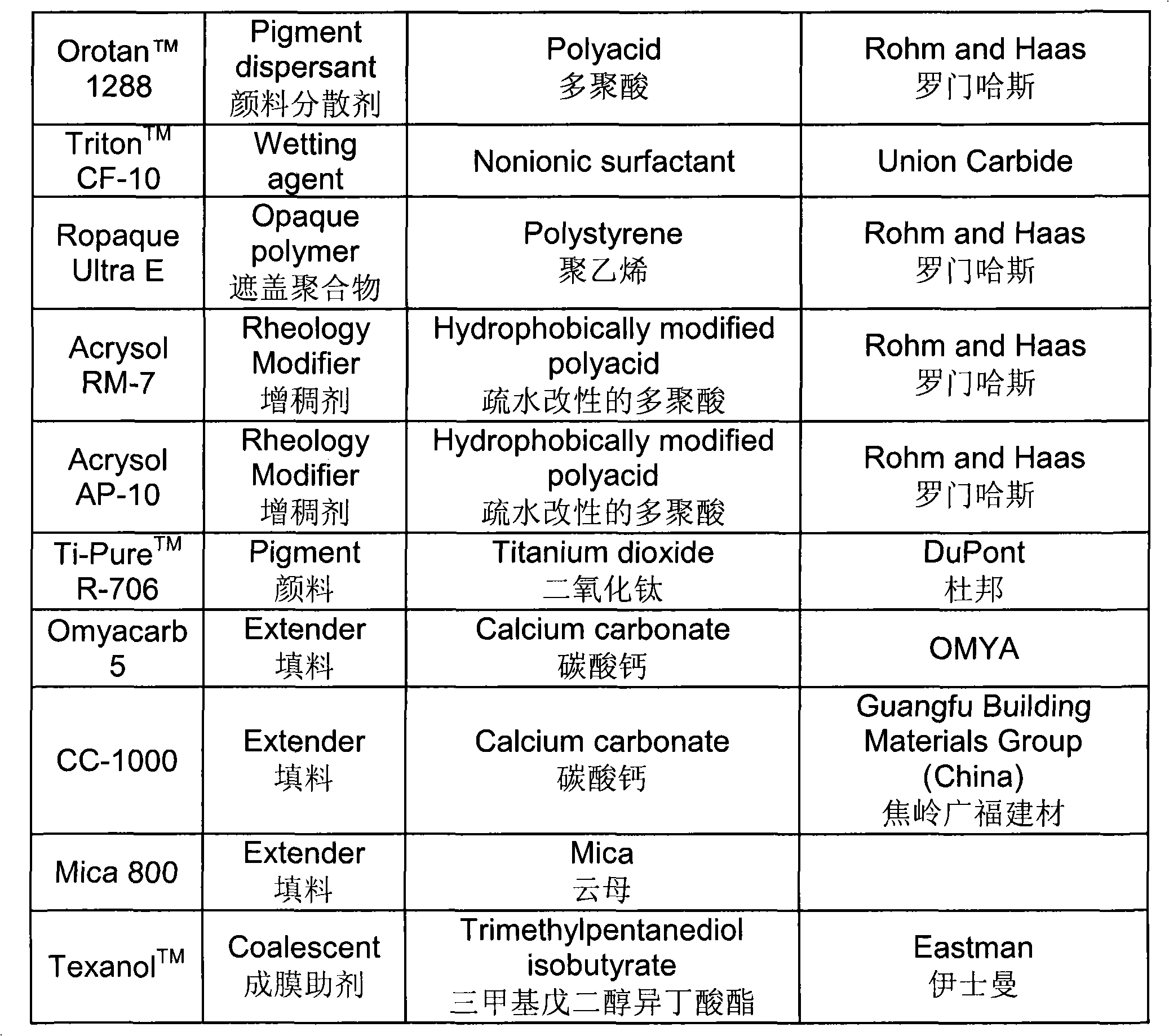

[0095] An aqueous coating composition containing the aqueous copolymer emulsion 1 was prepared using the following procedure: Table 4 lists the components of the beating process, which needs to be dispersed using a Cowles disperser. The ingredients in the letdown section of Table 4 were added using a conventional laboratory mixer. The resulting coating had a PVC of 40.0% and a percent solids mention of 38.0%.

[0096] Paint 2-4

[0097] Coatings 2-4 (both containing Emulsion 1) were prepared according to the preparation method of Coating 1. The difference from Paint 1 is that Paints 2-4 also contained paraffin wax emulsion (Michem TM Emulsion 62330 or 77030) or sulfur-containing surfactant (sodium lauryl sulfate), the type and amount of paraffin wax emulsion and sulfur-containing surfactant contained in Table 5 are listed. In addition, it is necessary to adjust the dosage of Acrysol RM-7...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com