Method for treating three-layer soft foundation by using I-shaped mixing pile

A technology of weak foundation and mixing piles, which is applied in the direction of sheet pile walls, foundation structure engineering, construction, etc., can solve the problems of waste and engineering waste, and achieve the effect of saving the cost of foundation treatment projects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0013] A method of using I-shaped mixing piles to deal with three-layer weak foundations:

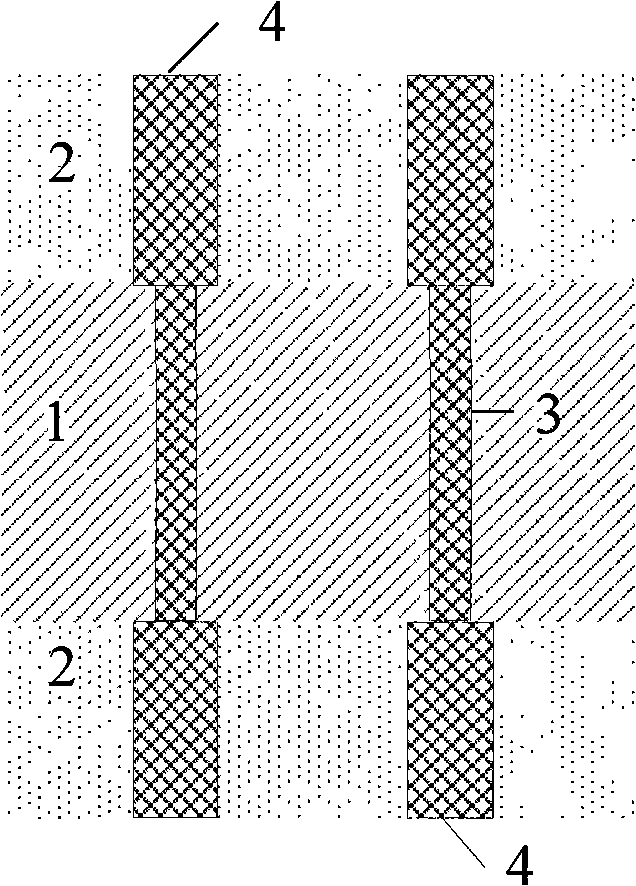

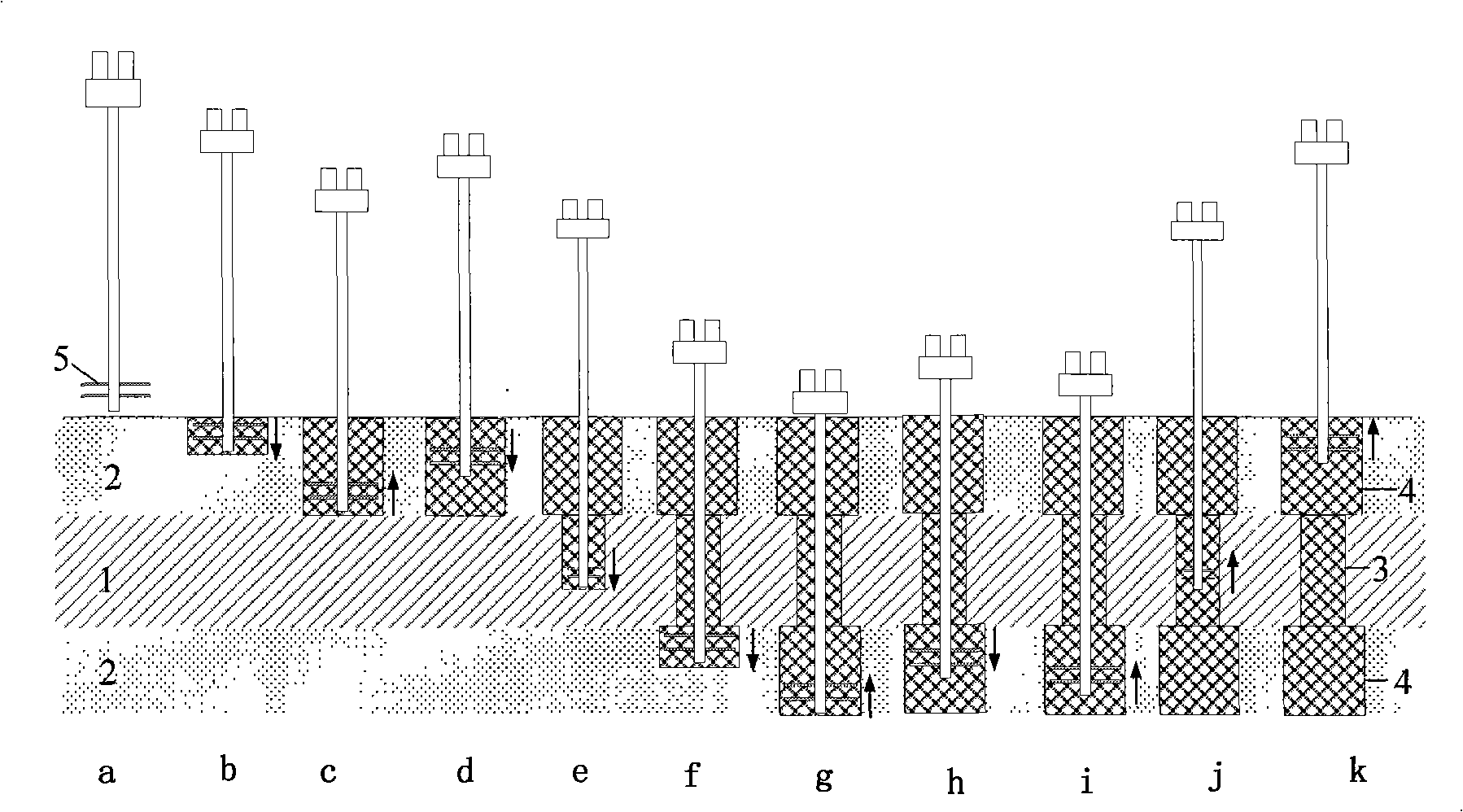

[0014] Choose to arrange I-shaped mixing piles on the three-layer soft foundation with the upper and lower parts as soft soil layers and the middle as hard soil layers. The I-shaped mixing piles are composed of small diameter piles in the middle and larger diameters. The expansion head is formed, the small pile in the middle is arranged in the hard soil layer in the middle, and the enlargement heads in the upper part and the lower part are arranged in the soft soil layer in the upper part and the lower part.

[0015] In this example,

[0016] I-shape mixing piles adopt plum blossom-shaped cloth piles or square cloth piles, and use a retractable blade mixing pile machine to form piles.

[0017] In this embodiment, the piles are constructed with stirring blades that can be expanded into two different diameters. In the hard soil layer, the stirring blades shrink to the diameter of the sma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com