Hermetic, circular, heating and energy saving process and device for extracting super thick oil by saturated vapor in hollow rod

A technology of closed circulation and oil production equipment, which is applied in the direction of production fluid, earthwork drilling and production, wellbore/well components, etc. It can solve the problems that cannot meet the development needs of super heavy oil, limit the application and development, and consume a lot of energy, and achieve energy saving Remarkable consumption reduction effect, reduced mining cost, high heat effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

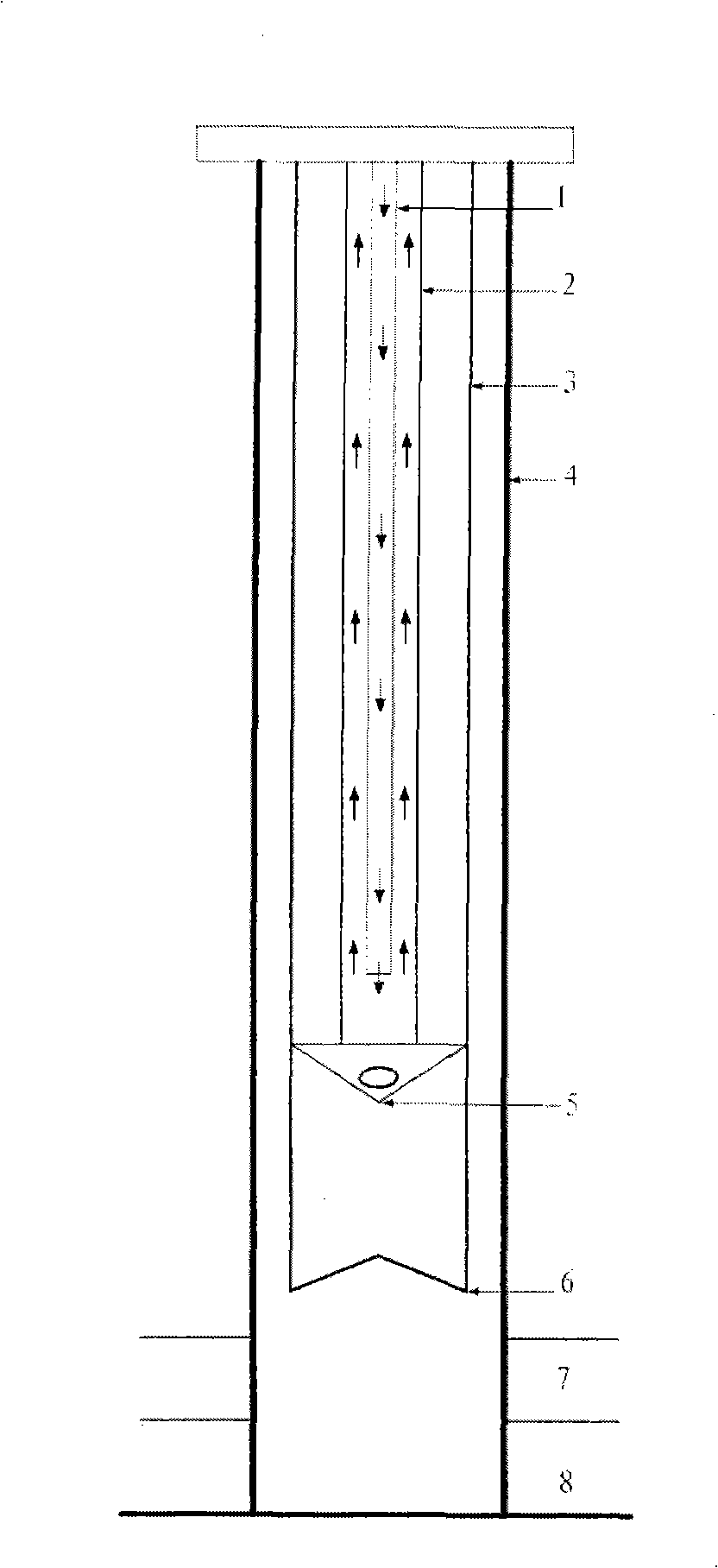

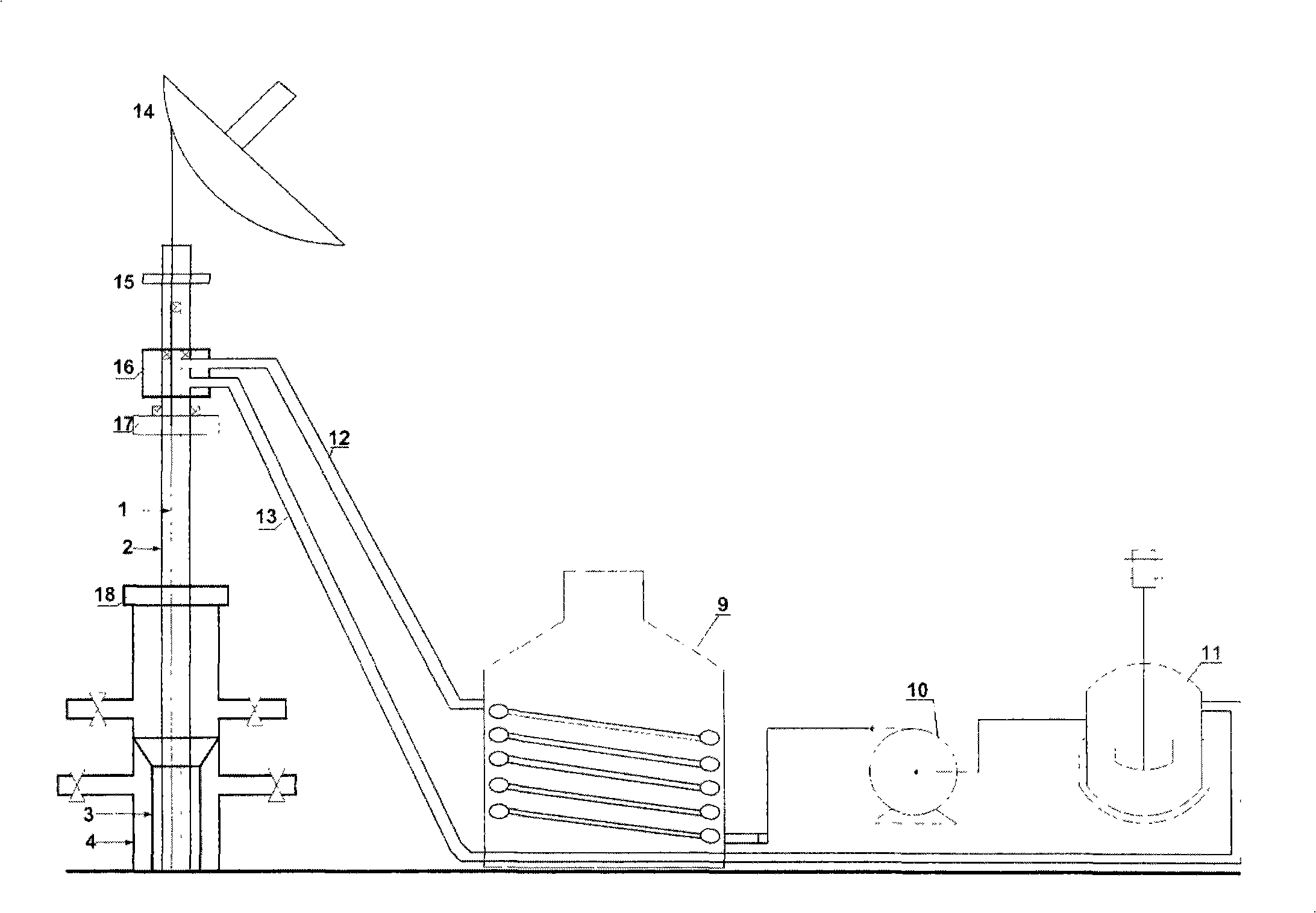

[0017] An energy-saving oil recovery process for super heavy oil hollow rod saturated steam closed cycle heating, which includes injecting saturated steam from the surface to the downhole through the hollow rod. The injection of the saturated steam is carried out by the ultra-heavy oil hollow rod saturated steam heating oil recovery process device, which is injected from the ground part of the device to the wellbore part, and returns to the ground part, so that the closed cycle heats the temperature of the super heavy oil in the pipe to 70-150 °C , reduce the viscosity of the super heavy oil, and the super heavy oil after the viscosity reduction is extracted from the ground by the deep well pump.

[0018] The closed cycle is from the pressure buffer tank 11 of the device → the multi-stage centrifugal pump 10 → the heating furnace → the high temperature resistant and heat-insulated continuous inner tube 1 and the annular space of the hollow sucker rod 2 → to the pressure buffer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com