Crude oil mixed-transferring integrated device and method

An integrated device and crude oil technology, applied in the pipeline system, mechanical equipment, gas/liquid distribution and storage, etc., can solve the problems of long production and construction period, high investment, inconvenient operation and maintenance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

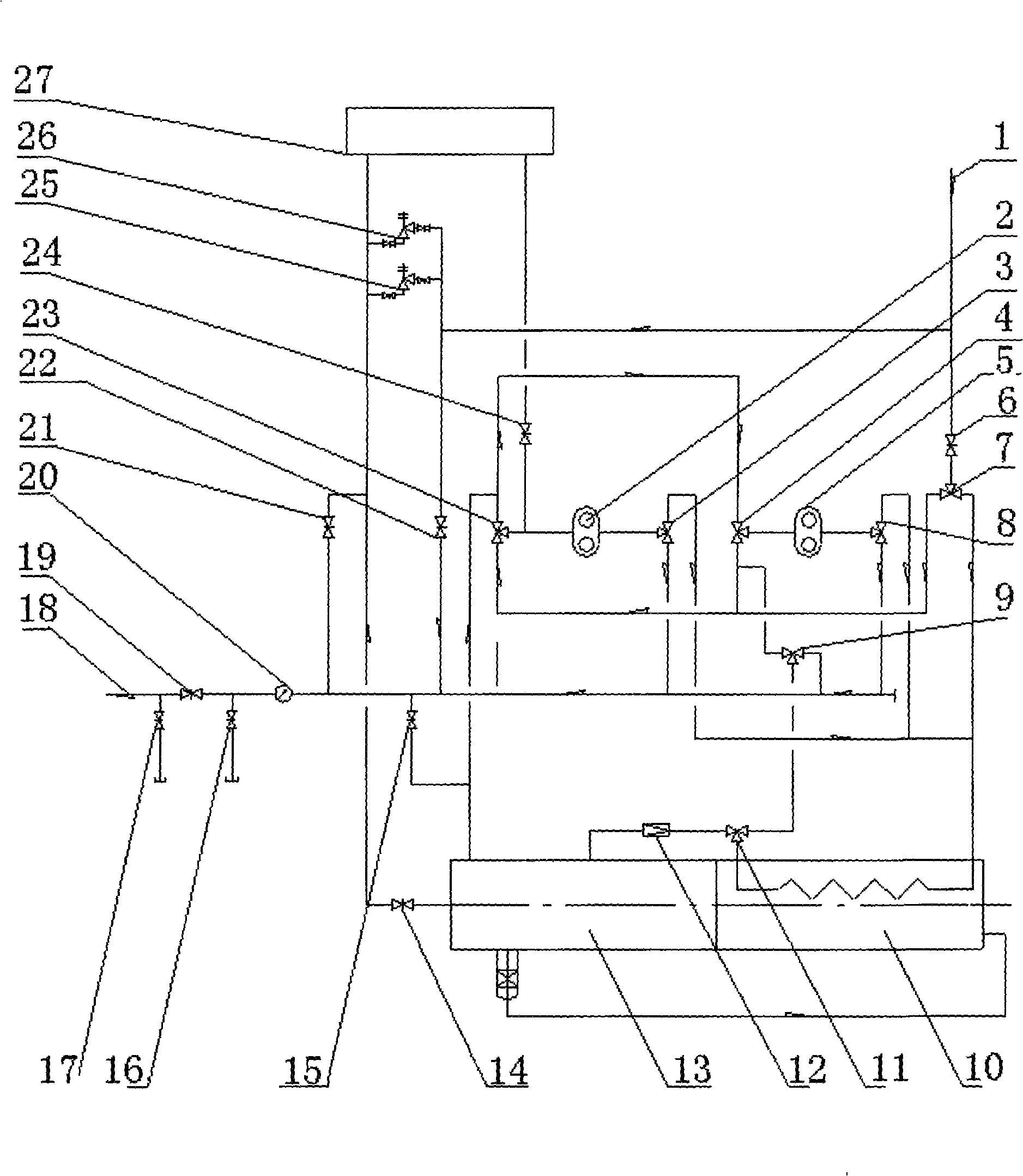

[0024] Such as figure 1 As shown, the crude oil multi-process mixed transportation integrated device includes at least the first booster 2, the first three-way valve 3, the second three-way valve 4, the second booster 5, the main oil valve 6, the third Three-way valve 7, fourth three-way valve 8, fifth three-way valve 9, heating device 10, three-way regulating valve 11, pressure reducing valve 12, separation buffer device 13, first gate valve 14, second gate valve 15, the first Three-gate valve 16, fourth gate valve 17, crude oil export port 18, main export valve 19, metering device 20, fifth gate valve 21, sixth gate valve 22, sixth three-way valve 23, seventh gate valve 24, first safety valve Valve 25, second safety valve 26 and production operation box 27, in which the incoming oil from the well group passes through the oil port 1 of the main engine, and the oil incoming main valve 6 is connected with a bypass port of the third three-way valve 7, and the third three-way On...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com