Multifunctional liquid injection cap of lead acid storage battery for traction

A lead-acid battery and liquid injection cap technology, applied in the field of liquid injection caps, can solve problems such as wasted labor, convenience obstacles, and battery life reduction, and achieve the effects of preventing liquid shortage, protecting the environment, and reducing maintenance costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

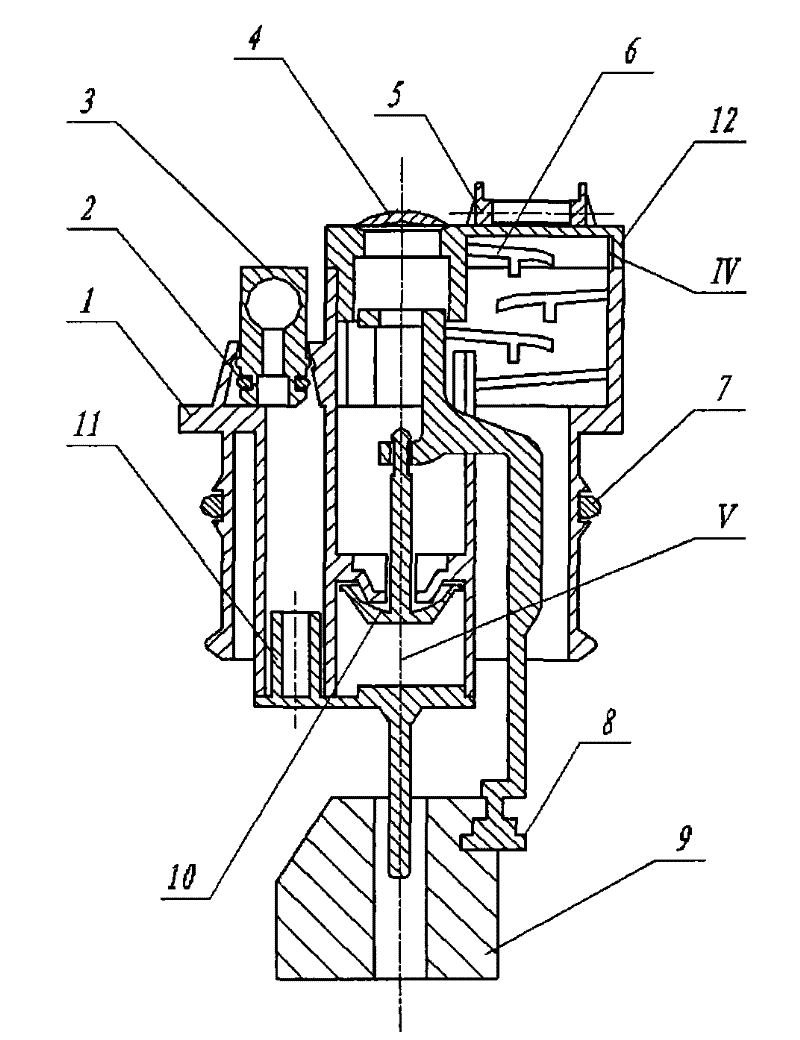

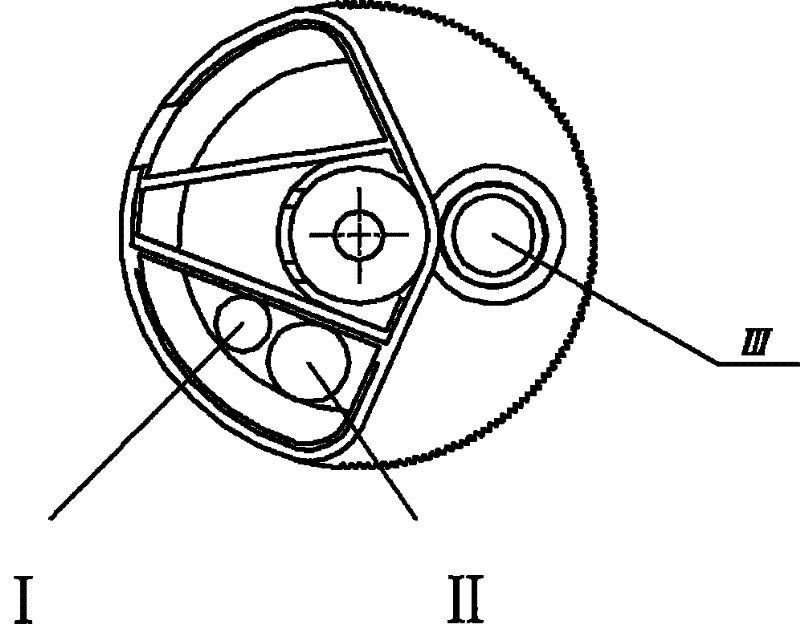

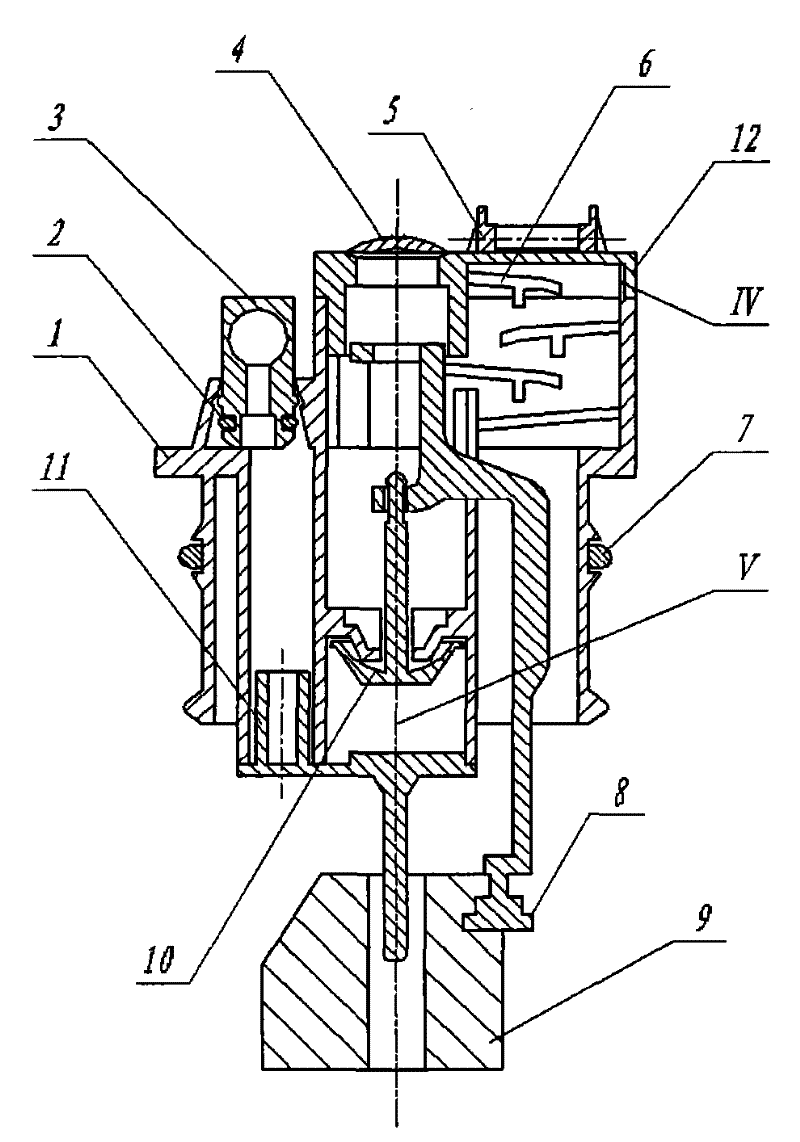

[0015] Depend on figure 1 It is known that the multifunctional liquid injection cap of the lead-acid battery for traction includes a housing 1, a cap cover and a device for controlling the liquid level. The inner cavity of the housing 1 is provided with a device for controlling the liquid level. The device for controlling the liquid level is determined by measuring The float 9 of the height of the liquid level, the choke plug 10 that can control whether to add liquid according to the height of the float, and the float connecting rod 8 are composed; the device for controlling the liquid level is: it also includes a liquid filling hole of the battery cover, and the outer diameter of the housing 1 is the same as the The inner diameters of the liquid filling holes of the battery cover are equal; the material of the multifunctional liquid filling cap is flame-resistant plastic. Connect the tee 3 for connection with the liquid injection hole III, and install a rubber sealing ring 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com