Configuration method of high-voltage transmission line insulator

A technology for high-voltage transmission lines and high-voltage lines, applied in suspension/strain insulators, overhead lines/cable equipment, etc., can solve problems such as insufficient insulation margin, low accuracy, flashover risk or engineering waste, and achieve design insulation. Configure accurate and reliable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

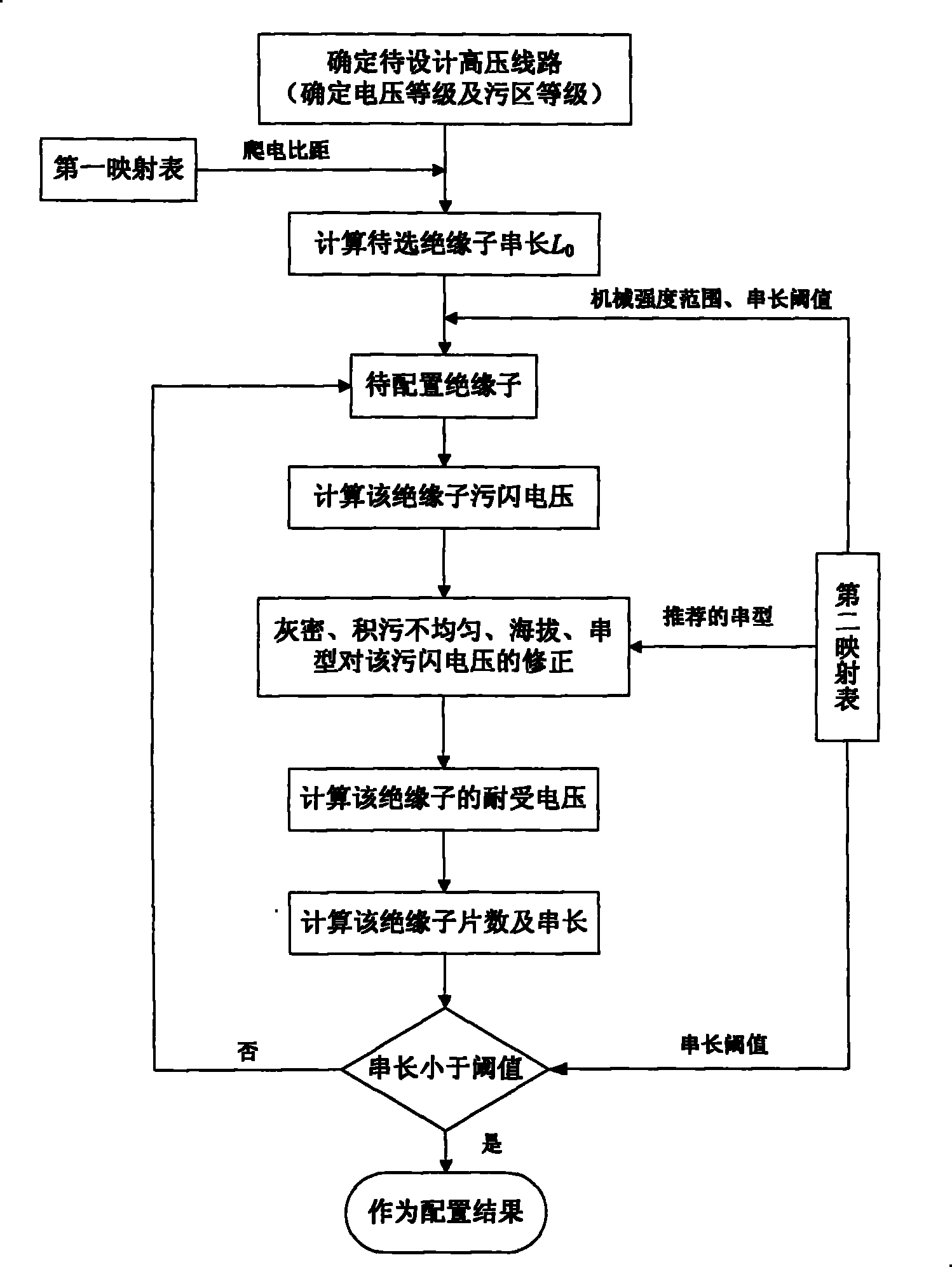

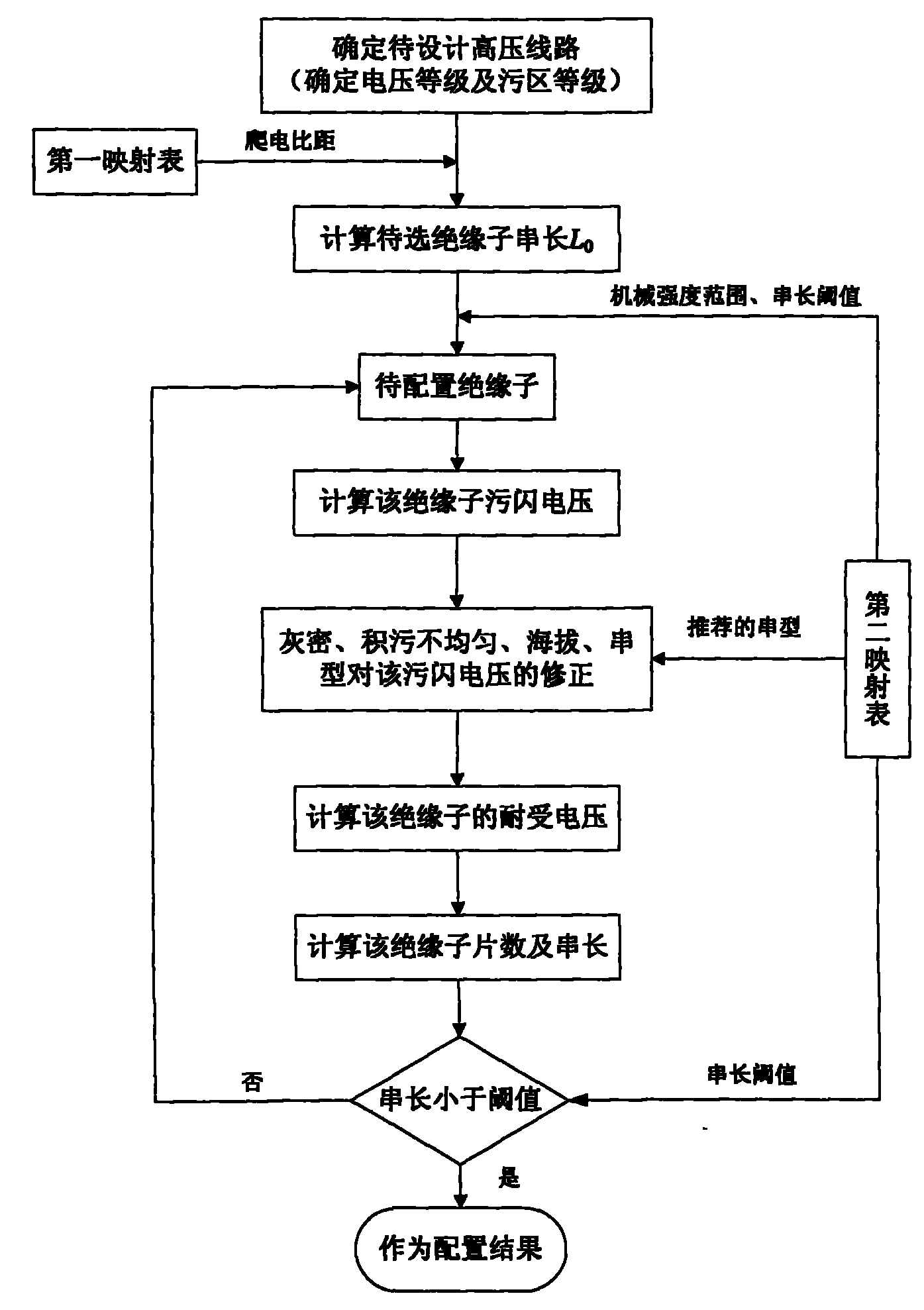

[0025] The configuration method of the high-voltage transmission line insulator proposed by the present invention has a flow chart as follows: figure 1 shown, including the following steps:

[0026] (1) Establish a first mapping table between pollution level and creepage ratio, and a second mapping table between voltage level and insulator string length threshold, insulator mechanical strength range, and insulator recommended string type;

[0027] (2) According to the pollution level of the high-voltage line to be designed, find the creepage distance from the above-mentioned first mapping table, and calculate the string length L of the insulator to be selected according to the creepage distance and the voltage level of the high-voltage line to be designed. 0 , according to the voltage level of the high-voltage line to be designed, find the insulator string length threshold from the second mapping table above, and set L 0 Compare with the search string length threshold, repeat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com