Urea grease composition

A technology of urea grease and composition, which is applied in the direction of lubricating composition, petroleum industry, thickener, etc., and can solve problems such as poor penetration, competition for urea grease, impossible to obtain grease, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

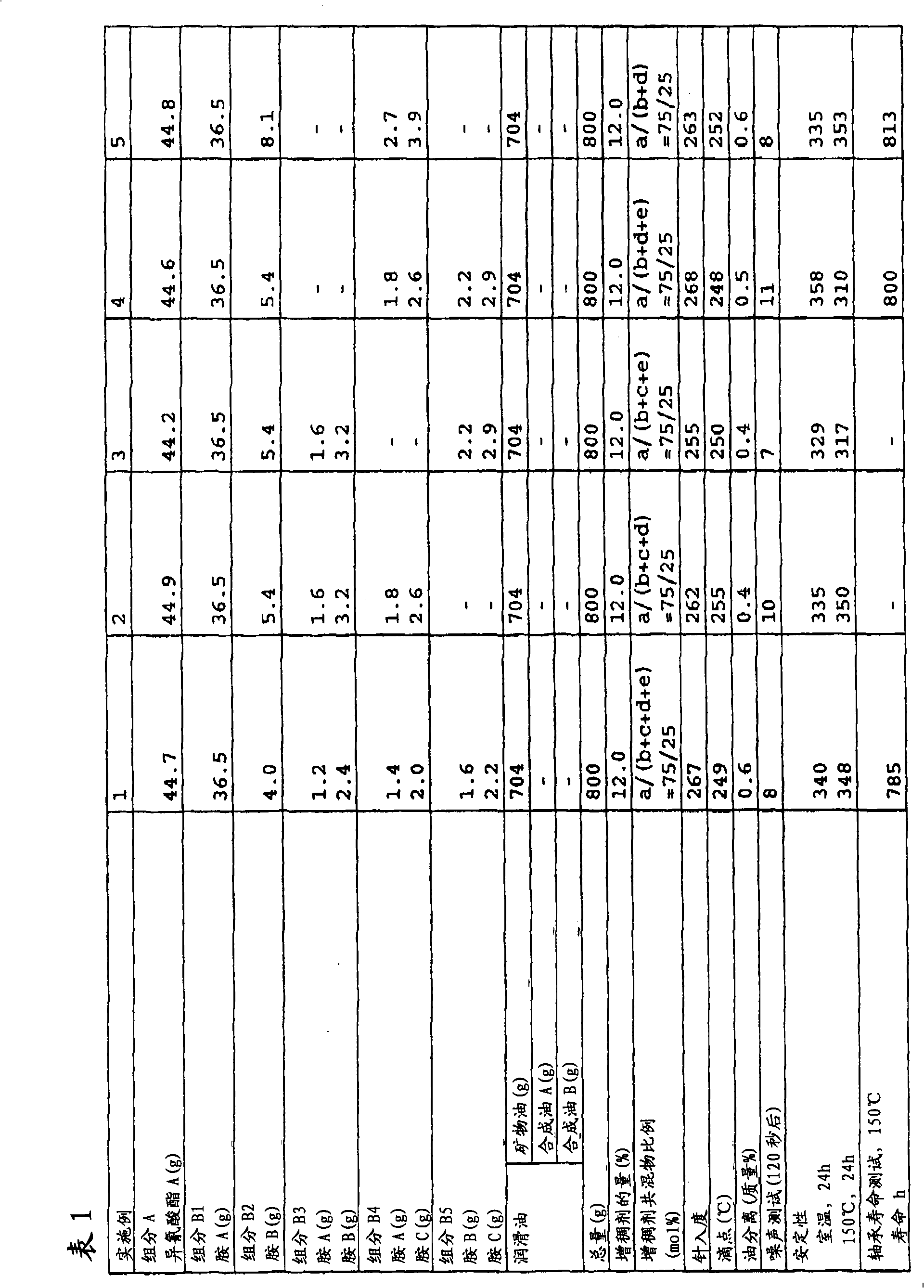

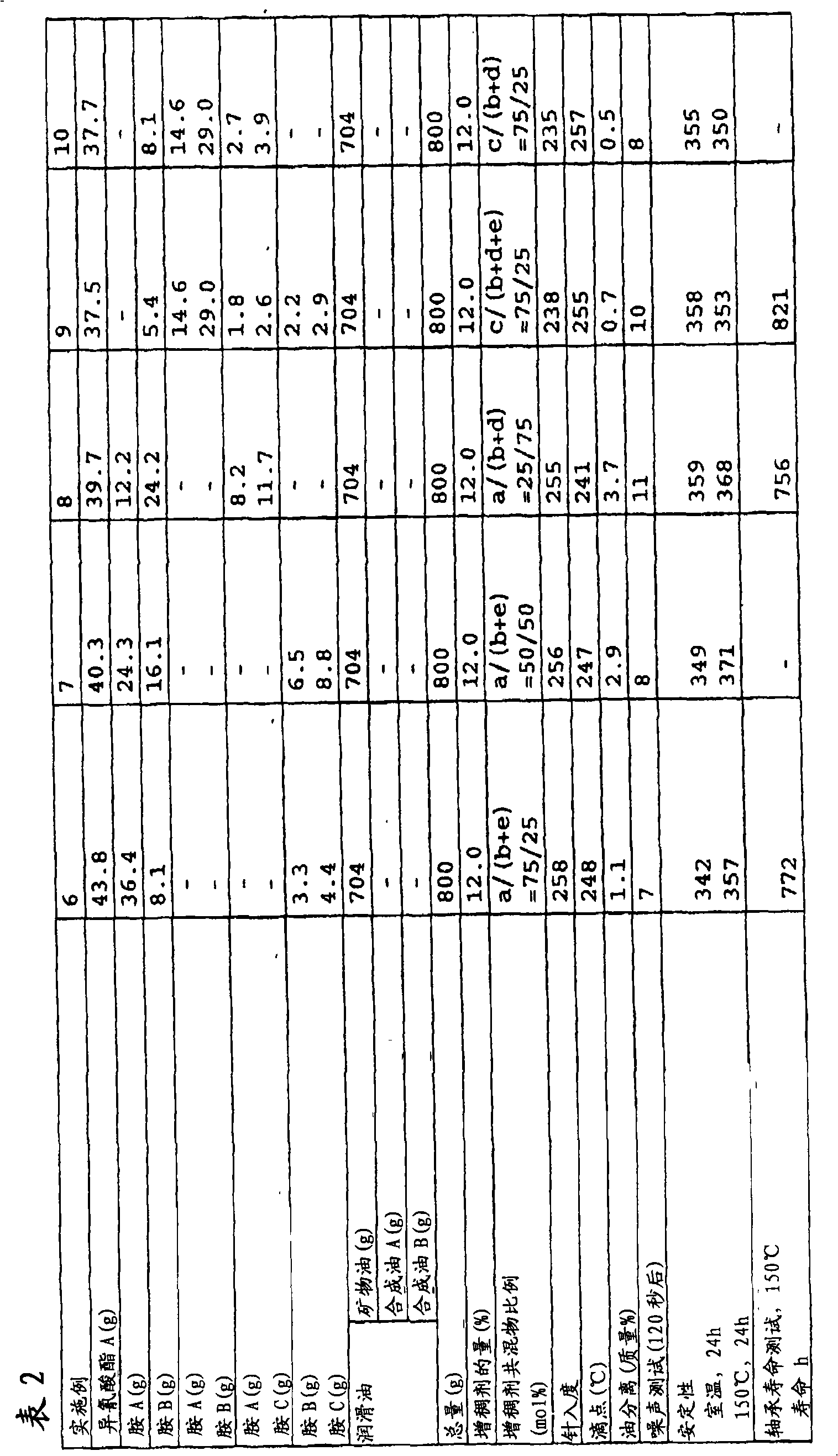

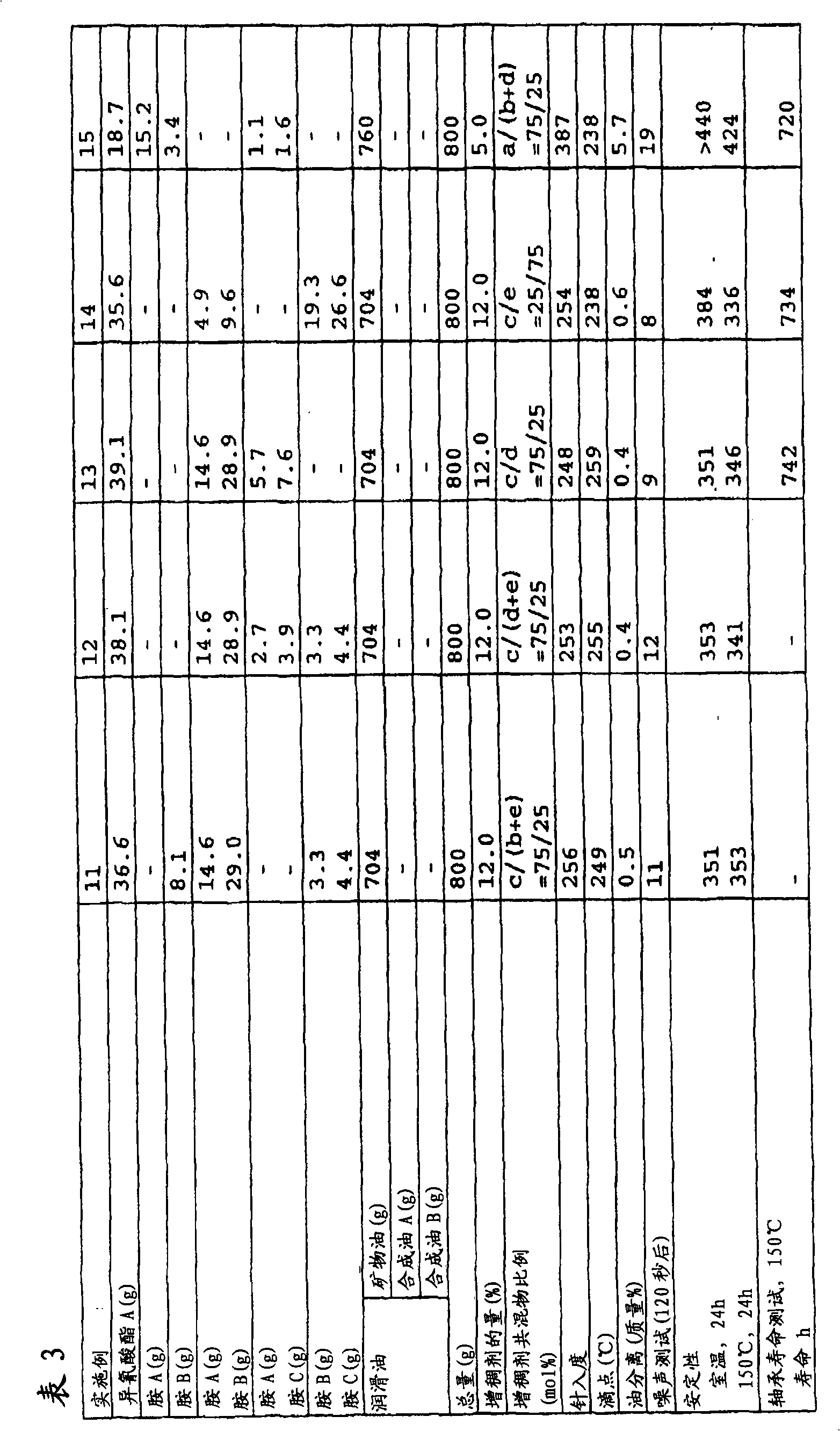

Embodiment 1

[0135] A closed prototype grease kettle apparatus was charged with lubricating base oil and isocyanate A (diphenylmethane-4,4'-diisocyanate) as component A and heated to 60°C with stirring. Amine A (technical octylamine) was added as component B1 and had been mixed in the lubricating base oil and reacted with component A. The urea compound 'a' represented by the general formula (octyl)-NHCONH-(diphenylmethane)-NHCONH-(octyl) was obtained. The contents were heated to about 80°C by the heat of reaction. This temperature was maintained for 10 minutes, then the amine B (technical oleylamine) as component B2 previously mixed and dissolved in the lubricating base oil was added to the kettle and reacted with the remaining isocyanate A as component A. A urea compound 'b' represented by the general formula (oleyl)-NHCONH-(diphenylmethane)-NHCONH-(oleyl) was obtained. After stirring for 5 minutes, add amine A (industrial octylamine) and amine B (industrial oleylamine) which are compon...

Embodiment 2

[0137] A closed prototype grease kettle apparatus was charged with lubricating base oil and isocyanate A (diphenylmethane-4,4'-diisocyanate) as component A and heated to 60°C with stirring. Amine A (technical octylamine) was added as component B1 and had been mixed in the lubricating base oil and reacted with component A. The urea compound 'a' represented by the general formula (octyl)-NHCONH-(diphenylmethane)-NHCONH-(octyl) was obtained. The contents were heated to about 80°C by the heat of reaction. This temperature was maintained for 10 minutes, then the amine B (technical oleylamine) as component B2 previously mixed and dissolved in the lubricating base oil was added to the kettle and reacted with the remaining isocyanate A as component A. A urea compound 'b' represented by the general formula (oleyl)-NHCONH-(diphenylmethane)-NHCONH-(oleyl) was obtained. After stirring for 5 minutes, add amine A (industrial octylamine) and amine B (industrial oleylamine) which are compon...

Embodiment 3

[0139] A closed prototype grease kettle apparatus was charged with lubricating base oil and isocyanate A (diphenylmethane-4,4'-diisocyanate) as component A and heated to 60°C with stirring. Amine A (technical octylamine) was added as component B1 and had been mixed in the lubricating base oil and reacted with component A. The urea compound 'a' represented by the general formula (octyl)-NHCONH-(diphenylmethane)-NHCONH-(octyl) was obtained. The contents were heated to about 80°C by the heat of reaction. This temperature was maintained for 10 minutes, then the amine B (technical oleylamine) as component B2 previously mixed and dissolved in the lubricating base oil was added to the kettle and reacted with the remaining isocyanate A as component A. A urea compound 'b' represented by the general formula (oleyl)-NHCONH-(diphenylmethane)-NHCONH-(oleyl) was obtained. After stirring for 5 minutes, add amine A (industrial octylamine) and amine B (industrial oleylamine) which are compon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com