Method of producing polymer microparticles

一种高分子微粒、抗体的技术,应用在分析材料、仪器、测量装置等方向,能够解决测定结果可靠性丧失、高难度、无法准确疾病诊断等问题,达到避免非特异性反应、检测灵敏度高的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] The production method of the present invention is characterized in that an antigen or an antibody is allowed to coexist during miniemulsion polymerization. According to the production method of the present invention, polymer particles (especially latex particles) (hereinafter referred to as partner-introduced polymer particles) in which the above-mentioned antigen or antibody is introduced into the surface of polymer particles (especially latex particles) can be produced. .

[0026] In addition to allowing the antigen or antibody to coexist during the polymerization reaction, the preparation method of the present invention can be combined with conventionally known miniemulsion polymerization (such as M.Antonietti, K.Landfester, Prog.Polym.Sci., 2002, 27, 689-757, J.M.Asua, Prog.Polym.Sci., 2002, 27, 1283-1346) is also carried out.

[0027] Common miniemulsion polymerization may include, for example, the steps of mixing monomers, radical polymerization initiators, emuls...

Embodiment 1

[0058] "Example 1: Preparation of Anti-Bovine Serum Albumin (BSA) Antibody Determination Reagent"

[0059] (1) Preparation of BSA-introduced latex particles

[0060] 40mmol styrene, 4mmol hexadecane, 200mg BSA, 0.8mmol CH 2 =C(CH 3 )COO(CH 2 CH 2 O) 23 CH 3 (NK Ester M-230G, Shin-Nakamura Chemical Industry Co., Ltd.), 0.4mmol ascorbic acid and 20g water were mixed, under 80% output power, 50% pulse, implemented 15 minutes ultrasonic treatment under ice bath (UH-300: Co., Ltd. Esuemte 1). Added in the three-necked flask, while stirring at 100rpm, implemented nitrogen bubbling for 15 minutes, and then added 0.4mmol H 2 o 2 , and polymerized at 30° C. or 60° C. for 6 hours while stirring at 200 rpm to prepare BSA-introduced latex particles. The average particle diameters of the obtained BSA-introduced latex particles were 0.109 μm (at 30° C.) and 0.121 μm (at 60° C.).

[0061] (2) Preparation of BSA-introduced latex particle suspension

[0062] 1 mL of blocking reagent...

Embodiment 2

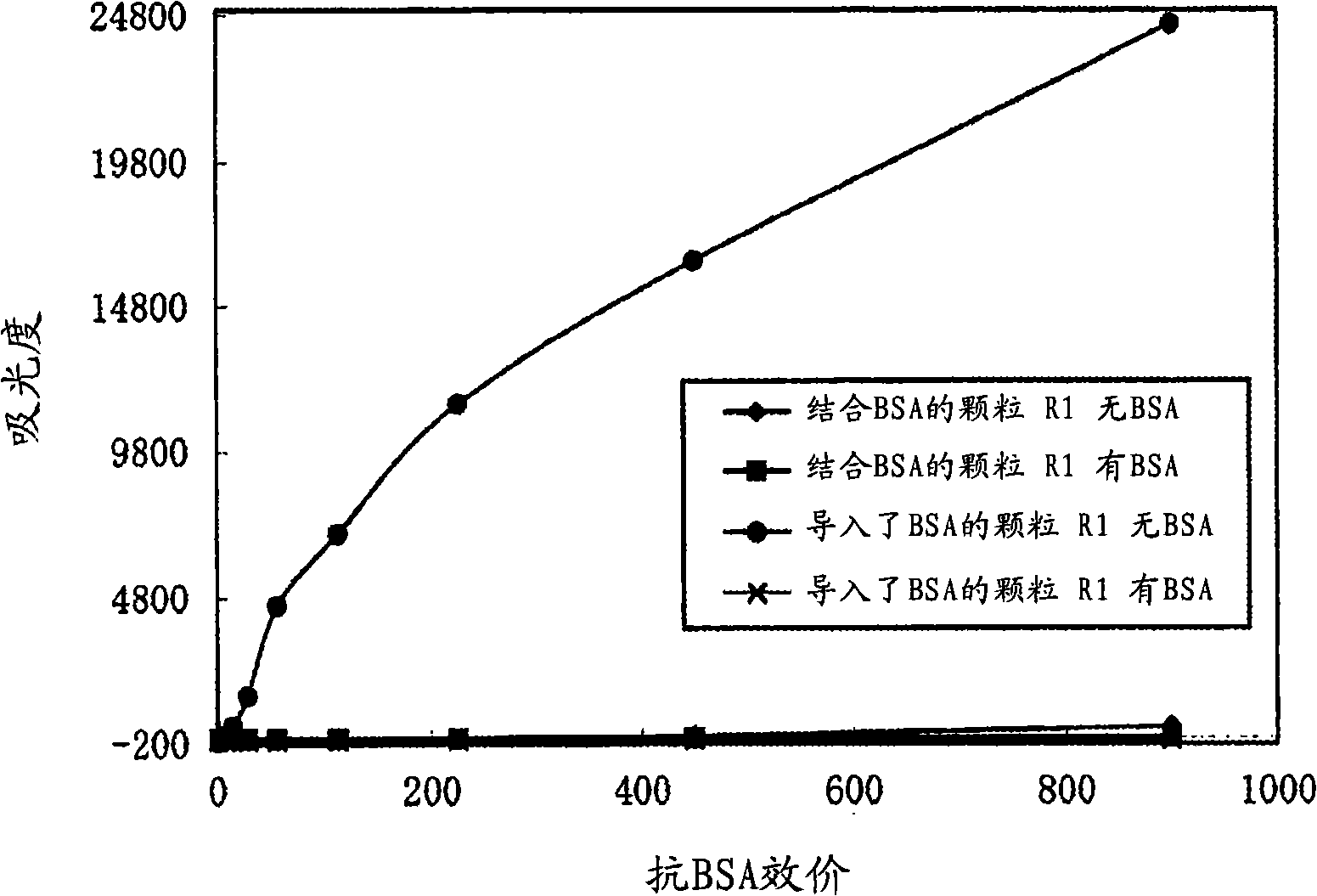

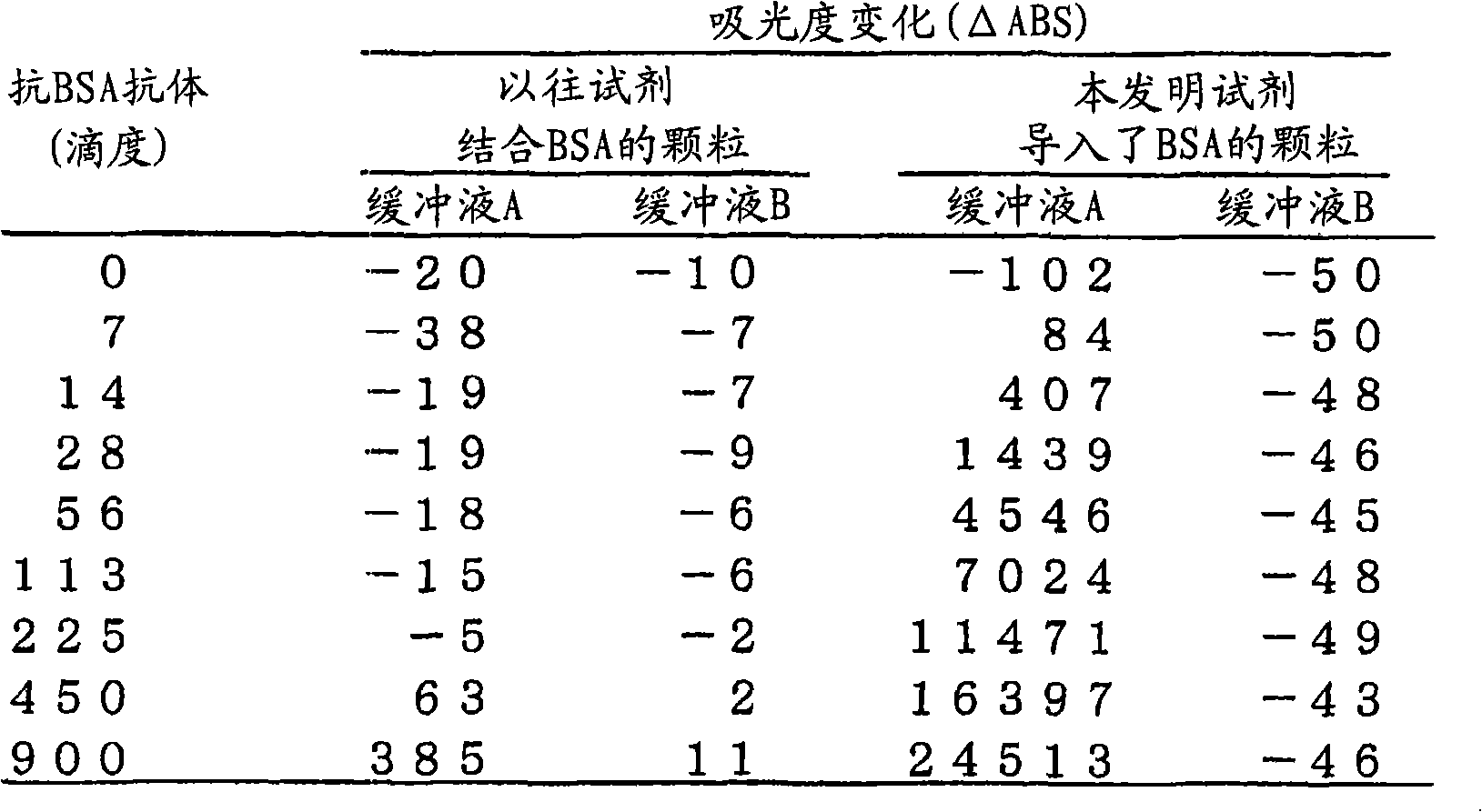

[0067] "Example 2: Determination of Anti-BSA Antibody Standard Solution"

[0068] (1) Preparation of anti-BSA antibody standard solution

[0069] Anti-BSA antibody (rabbit anti-bovine albumin, prepared by DAKO, 900 units) was diluted 2-fold with normal saline to prepare standard anti-BSA antibody dilution series with concentrations of 900, 450, 225, 113, 56, 28, 14 and 7 units.

[0070] (2) Determination of anti-BSA antibody standard solution

[0071] Mix 90 μL of the buffer A or B prepared in Example 1(3) in 15 μL of the standard anti-BSA antibody dilution series, keep it properly at 37°C, and then add 90 μL of the BSA-introduced latex prepared in Example 1(2) The particle suspension was stirred, and the absorbance was measured at a wavelength of 800-570 nm after 5 minutes. The difference between the amount of change in absorbance at 570 nm and the amount of change in absorbance at 800 nm during this period was defined as the amount of change in absorbance (ΔAbs). The meas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com