Process for producing magnet

一种制造方法、磁铁的技术,应用在磁铁的制造领域,能够解决Br下降、化合物饱和磁化变小等问题,达到矩形比充分、磁特性的下降小、矩形比大的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

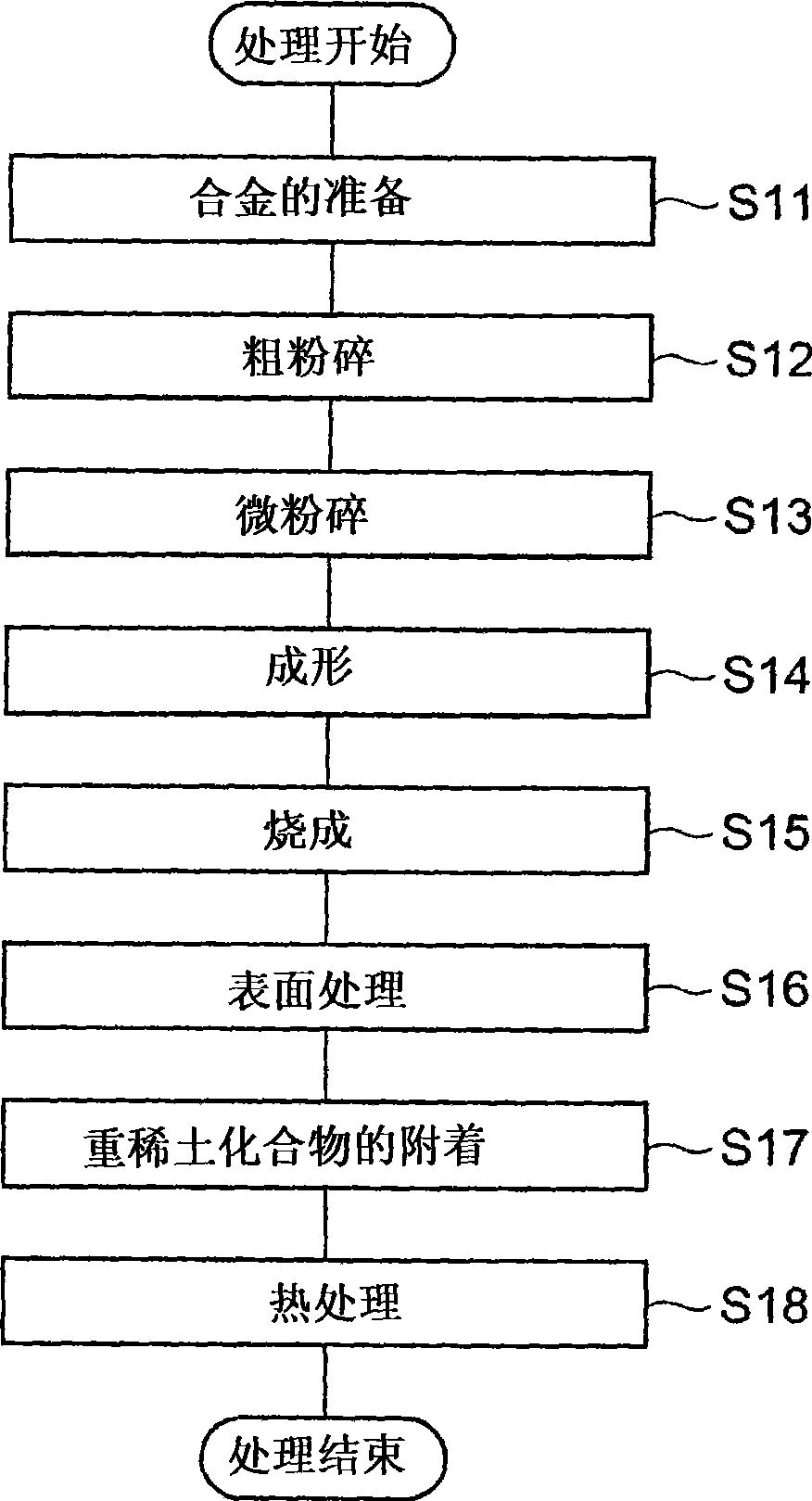

[0051] First, a raw material alloy is prepared so as to obtain an alloy having a composition of 24.00wt% Nd-1.00wt% Dy-5.30wt% Pr-0.450wt% Co-0.18wt% Al-0.06wt% Cu-1.00wt% B-balance Fe Rare earth magnets. As the raw material alloy, two kinds of a main phase-based alloy for mainly forming the main phase of the magnet and a grain boundary-based alloy for mainly forming grain boundaries were prepared. Subsequently, these raw material alloys were coarsely pulverized by hydrogen pulverization, and then subjected to high-pressure N 2 Air jet mill pulverization, each made into a fine powder with an average particle diameter D = 4 μm.

[0052] The obtained main phase alloy fine powder and grain boundary alloy fine powder were mixed at a ratio of the former: the latter = 95:5 to prepare a magnetic powder as a raw material powder of a rare earth magnet. Subsequently, using the magnetic powder, the molding pressure is 1.2t / cm 2 , Molding in a magnetic field was performed under the con...

Embodiment 2、3

[0057] Rare earth magnets were produced in the same manner as in Example 1, except that the dried sintered bodies were heat-treated at 900°C (Example 2) and 1000°C (Example 3), respectively.

Embodiment 4~6

[0078] First, a raw material alloy was prepared so as to obtain a rare earth magnet having a composition of 26.50wt% Nd-3.50wt% Dy-0.50wt% Co-0.22wt% Al-0.07wt% Cu-0.92wt% B-balance Fe. As the raw material alloy, two kinds of a main phase-based alloy for mainly forming the main phase of the magnet and a grain boundary-based alloy for mainly forming grain boundaries were prepared. Subsequently, these raw material alloys were coarsely pulverized by hydrogen pulverization, and then subjected to high-pressure N 2 Air jet mill pulverization to obtain fine powders with an average particle diameter D=4 μm.

[0079] The obtained fine powder of the main phase alloy and the fine powder of the grain boundary alloy were mixed at a ratio of the former: the latter = 95:5 to prepare a magnetic powder as a raw material powder of a rare earth magnet. Subsequently, using the magnetic powder, the molding pressure is 1.2t / cm 2 , Molding in a magnetic field was performed under the condition of a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com