Smashing process of permanent ferrite pre-sintering material

A technology of permanent magnet ferrite and pre-sintered material, applied in the direction of grain processing, etc., can solve the problems of low production efficiency, unclear amount of steel balls, and poor product density.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

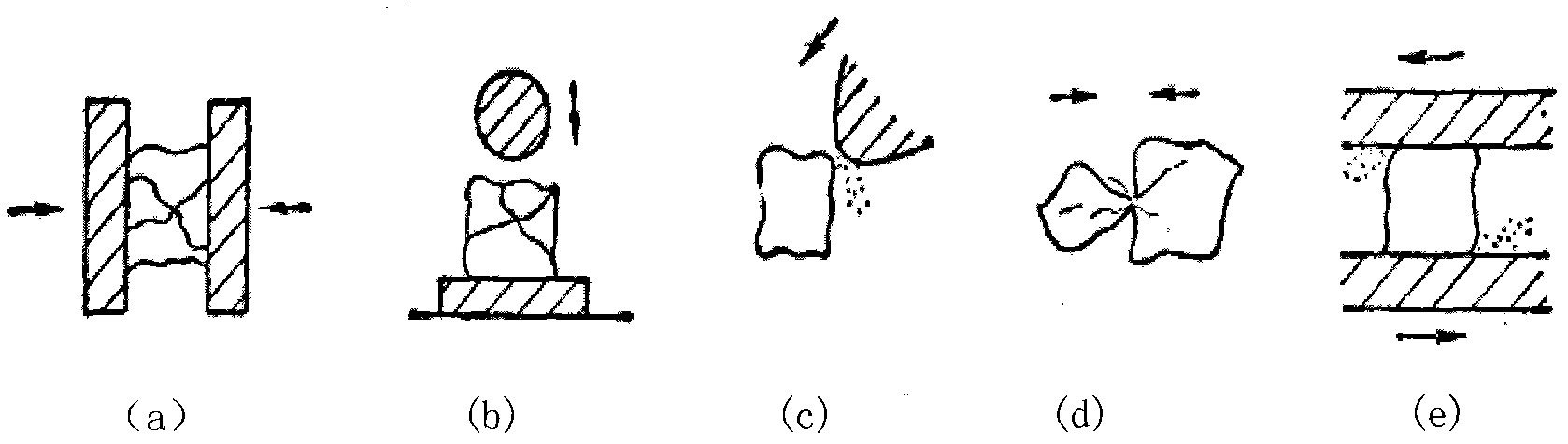

Problems solved by technology

Method used

Image

Examples

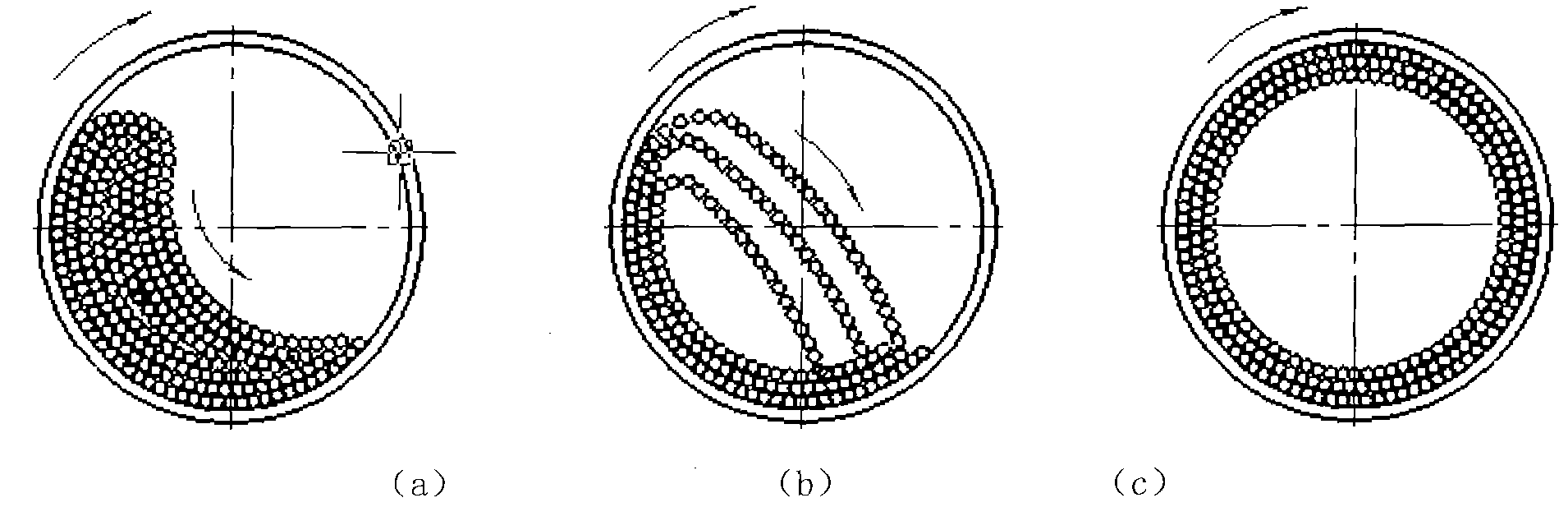

Embodiment 1

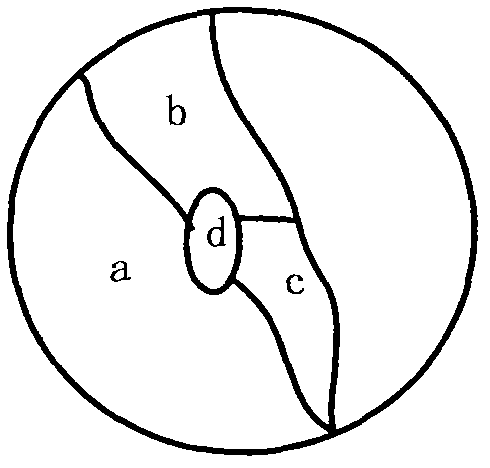

[0057] The improved ball mill is used to protrude upward in an arc shape, and the angle between the line connecting the highest point of the protrusion and one of the end points of the arc and the horizontal line is α=7°, such as Figure 6 As shown, the inner space size is φ1850×1950, the steel ball used is alloy steel, its HRC≥60, φ7.9mm, select the same batch of permanent magnet ferrite pre-fired material, after screening, its particle size is 3μm , each time the amount of abrasive is calculated as 1.5 tons, the mass fraction of 1.1% CaCO is added 3 , for 0.4% H 3 BO 3 , 0.36% SiO 2 , 0.8% SrCO 3 , for 1.2% La 2 o 3 , 0.5% Fe 2 o 3 , for 0.2% Co 3 o 4 , its material: ball: water=1: 4: 1.4, divide 2 stages, adopt different rotating speeds to grind, specifically, the first stage, the rotating speed of ball mill is 26 revs per minute, and the grinding time is 9 hours, grinds to 1.2 μm. The second stage is 20 rpm, 7 hours. Then, measure its average particle size with...

Embodiment 2

[0059] When crushing, the steel ball used is GCr15 bearing steel φ8mm, its HRC≥60, select the same batch of permanent magnet ferrite calcined material, after screening, its particle size is 5μm, and the first stage is ground to 1.25μm. All the other are controlled by embodiment 1, and its related statistical data are shown in table 2.

Embodiment 3

[0061] Select the same batch of permanent magnet ferrite calcined materials. After screening, the particle size is 5μm. The fine crushing process is divided into two stages. The steel balls are mixed balls of φ7.9mm and φ10mm. Among them, φ7. .9mm and φ10mm each account for 50%, and the rest are controlled according to Embodiment 1. The relevant statistical data are shown in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com