Iron-cobalt based nanocrystal alloy and preparation method thereof

A nanocrystalline alloy, iron-cobalt-based technology, used in magnetic materials, electrical components, circuits, etc., can solve the problem of inability to meet the requirements of high-frequency switching power supply magnetic saturation amplifier choke core use, low coercivity, high magnetic Conductivity etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

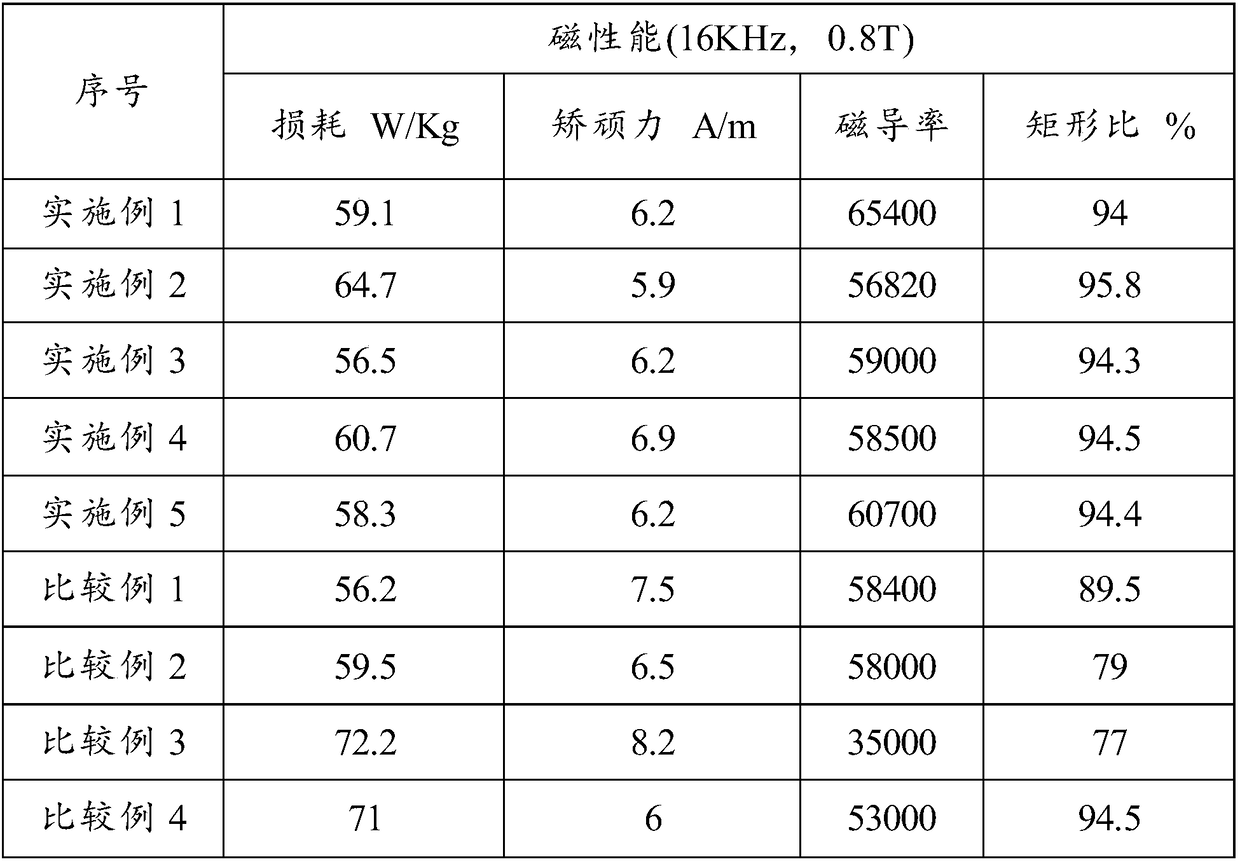

Examples

preparation example Construction

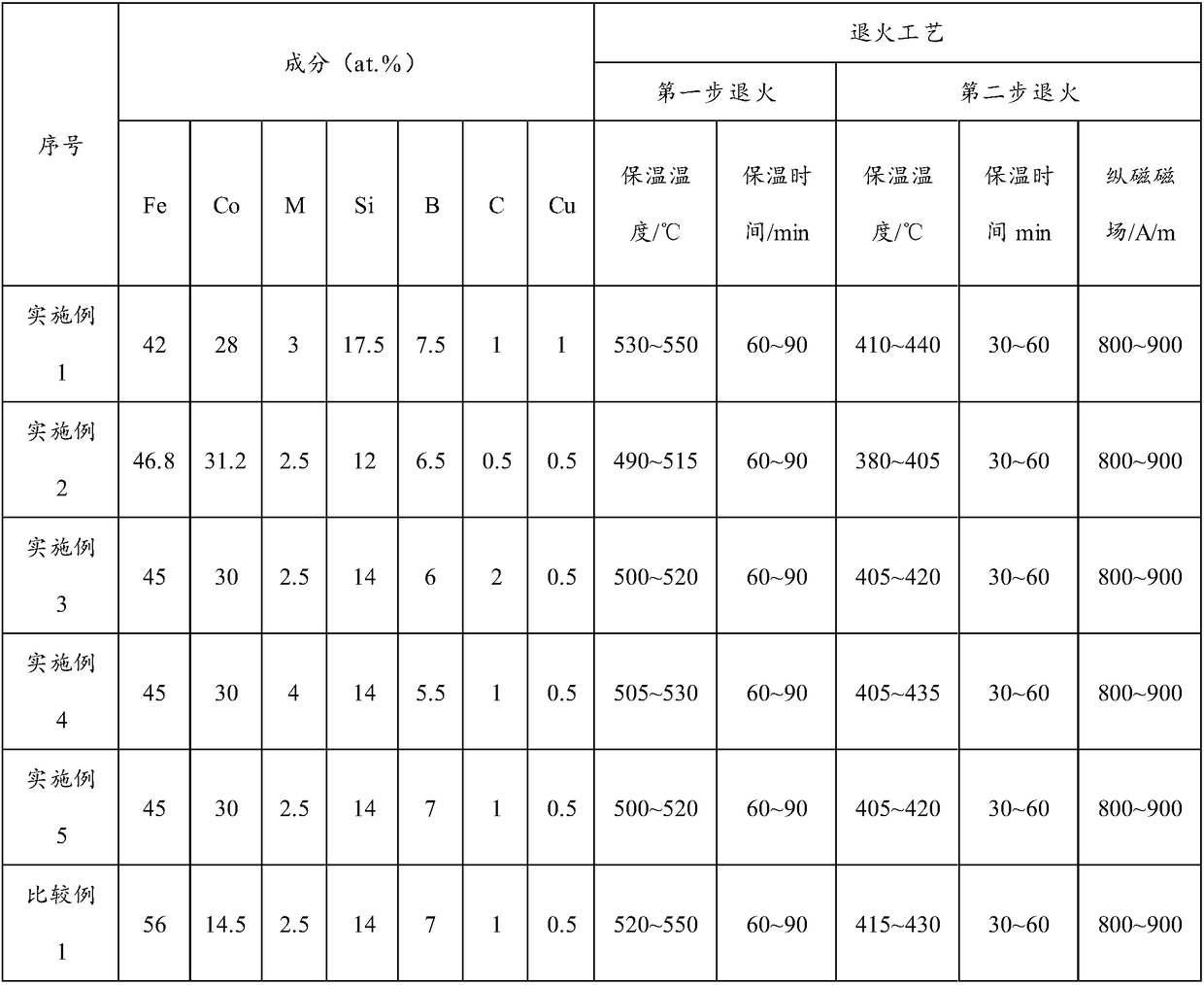

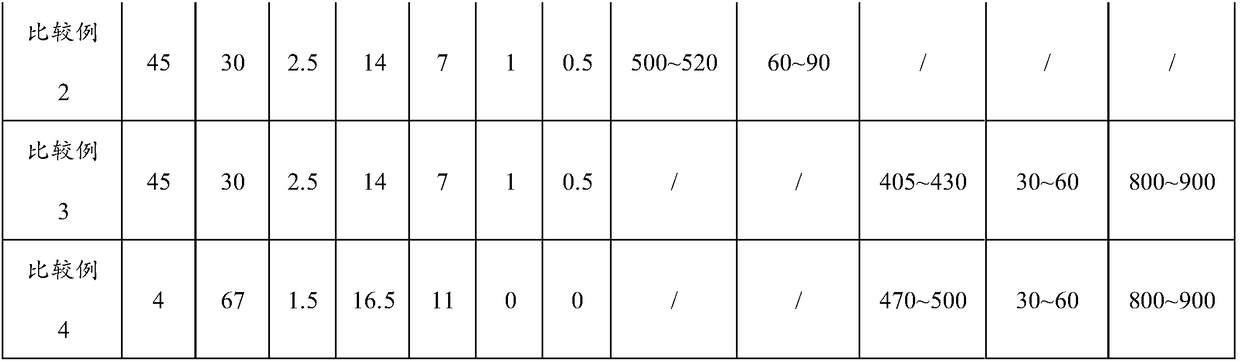

[0037] The present application also provides a method for preparing the above-mentioned iron-cobalt-based nanocrystalline alloy, comprising the following steps:

[0038] According to the formula (Fe 1-x co x ) a m b Si c B d C e Cu f The atomic percentage distribution ratio of the iron-based amorphous alloy is batched, and the raw materials after batching are smelted;

[0039] The smelted melt is subjected to single-roll rapid quenching to obtain iron-cobalt-based amorphous alloy thin strips;

[0040] The iron-cobalt-based amorphous alloy thin strip is annealed in the first step, and the iron-cobalt-based nano-gold alloy strip that has been annealed in the first step is annealed in the second step under the action of an longitudinal magnetic field to obtain iron-cobalt-based nanocrystals alloy;

[0041] Among them, a, b, c, d, e, f and x respectively represent the atomic percentage of the corresponding component; 0.3≤x≤0.45, 70≤a≤78, 1.5≤b≤4, 12≤c≤18, 4≤d≤8, 0.5≤e≤2,...

Embodiment

[0054] (1) According to the general formula of the composition (Fe 1-x co x ) a m b Si c B d C e Cu f For batching, where a, b, c, d, e, f and x represent the atomic percentage of the corresponding components: 0.3≤x≤0.45, 70≤a≤78, 1.5≤b≤4, 12≤c≤ 18, 4≤d≤8, 0.5≤e≤2, 0.3≤f≤1.2, a+b+c+d+e+f=100. M is an element in Cr, V, Mo, Nb, Zr;

[0055] (2) According to the ingredients in the above step (1), use an intermediate frequency induction melting furnace to melt the raw materials, and the maximum temperature of the molten steel during the smelting process does not exceed 1500°C;

[0056] (3) Adjust the molten steel temperature to 150-200°C above the alloy liquidus temperature, set the initial line speed of the copper roll to 21-28m / s, and prepare an iron-cobalt-based amorphous alloy thin strip by using a single-roll rapid quenching method; The initial thickness of the strip is 27-33μm. During the process, the distance between the nozzle and the copper roller is gradually re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com