A sole with non-return valve and membrane of hydrohobic and ventilated

A hydrophobic breathable membrane and one-way valve technology, which is applied in shoe soles, footwear, applications, etc., can solve the problems of affecting metabolism, easily invading the human body, interfering with daily life, work, etc., and achieving the effect of one-way circulation and waterproofing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with accompanying drawing.

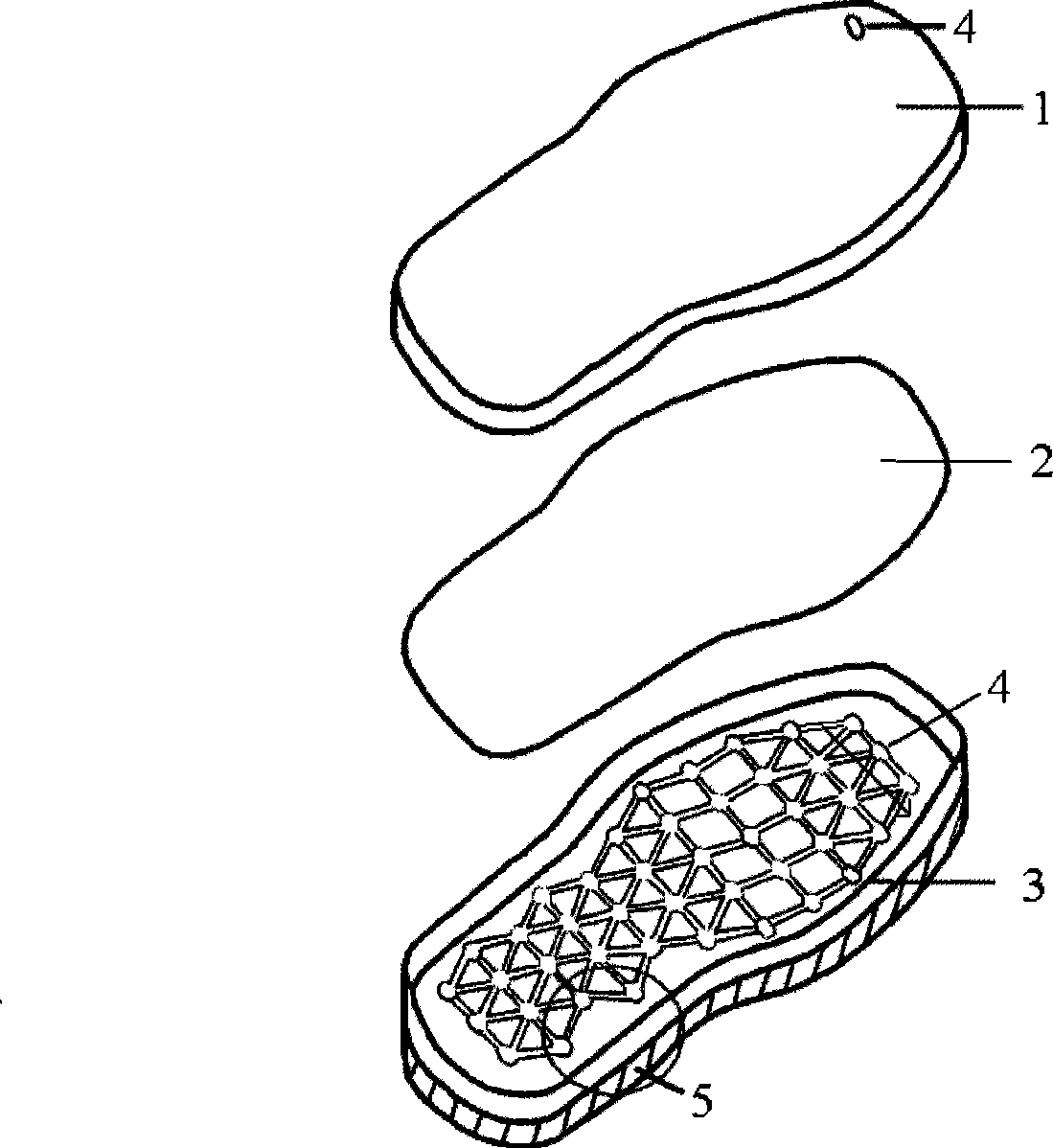

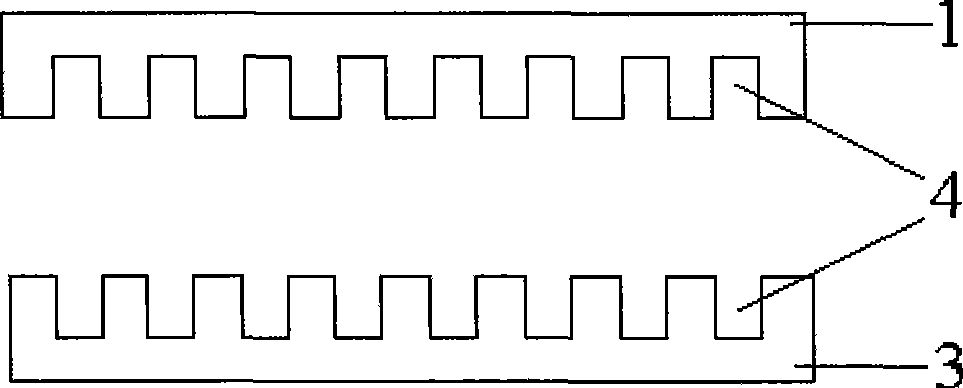

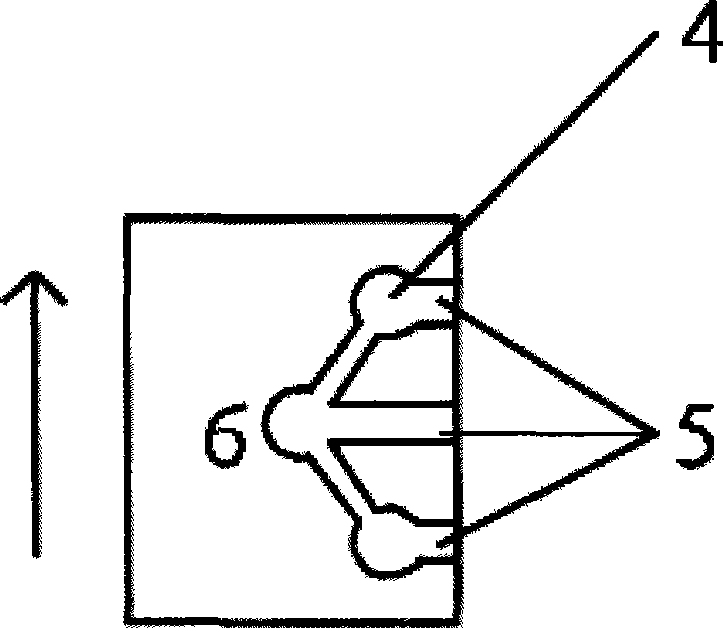

[0012] see Figure 1~3 , the sole includes an upper bottom 1, a lower bottom 3 and a hydrophobic and breathable membrane 2. The upper bottom 1 and the lower bottom 3 are injection molded with PU material, and microporous foamed polytetrafluoroethylene is used as the hydrophobic and breathable membrane 2. The lower bottom and the upper bottom There are no through-through air holes 4, wherein the openings of the air holes of the lower bottom face upwards, the openings of the air holes of the upper bottom face downward, the number and positions of the air holes of the upper bottom and the lower bottom correspond to the positions, and the air holes between the adjacent air holes of the lower bottom face downwards. A communication groove 6 is provided, and at least one one-way ventilation valve 5 communicating with the outside is provided on the outside of the lower bottom near ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com