Device for filtering water automatically driven by multi-stage water power

A hydraulic automatic and water filtration technology, applied in water/sewage treatment, water/sludge/sewage treatment, filtration circuit, etc., can solve problems such as unreasonable, water waste, complex structure, etc. Convenient, Versatile Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

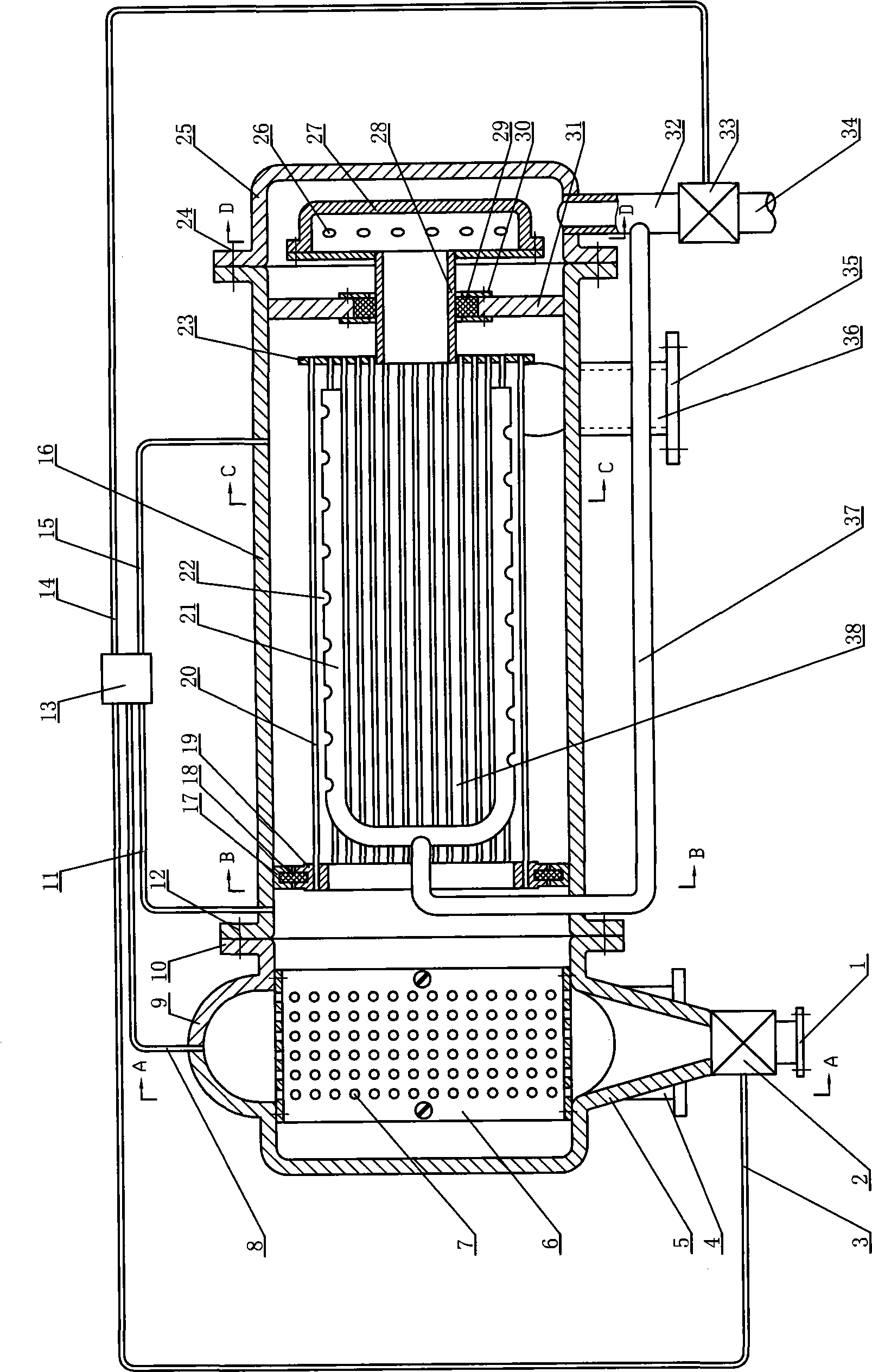

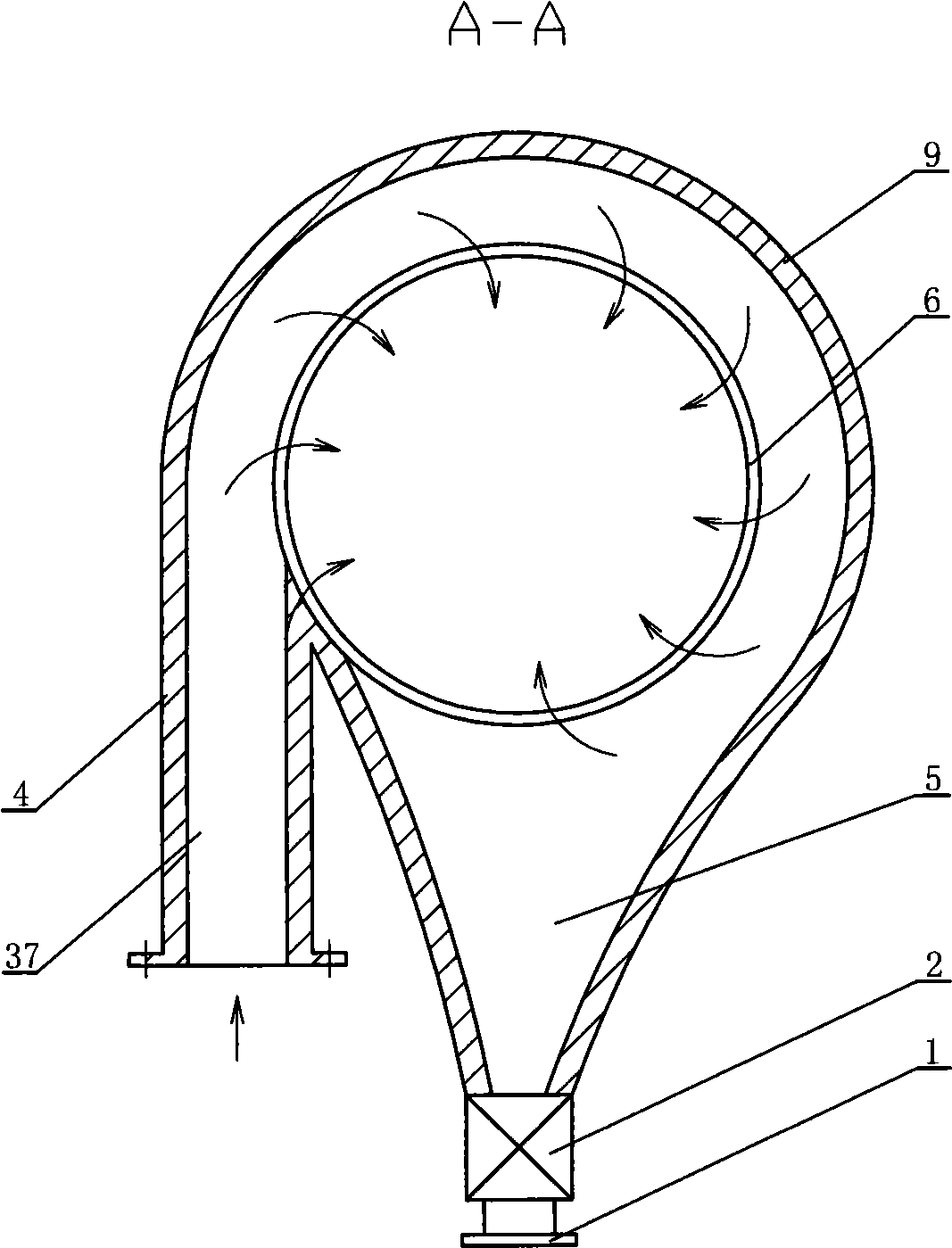

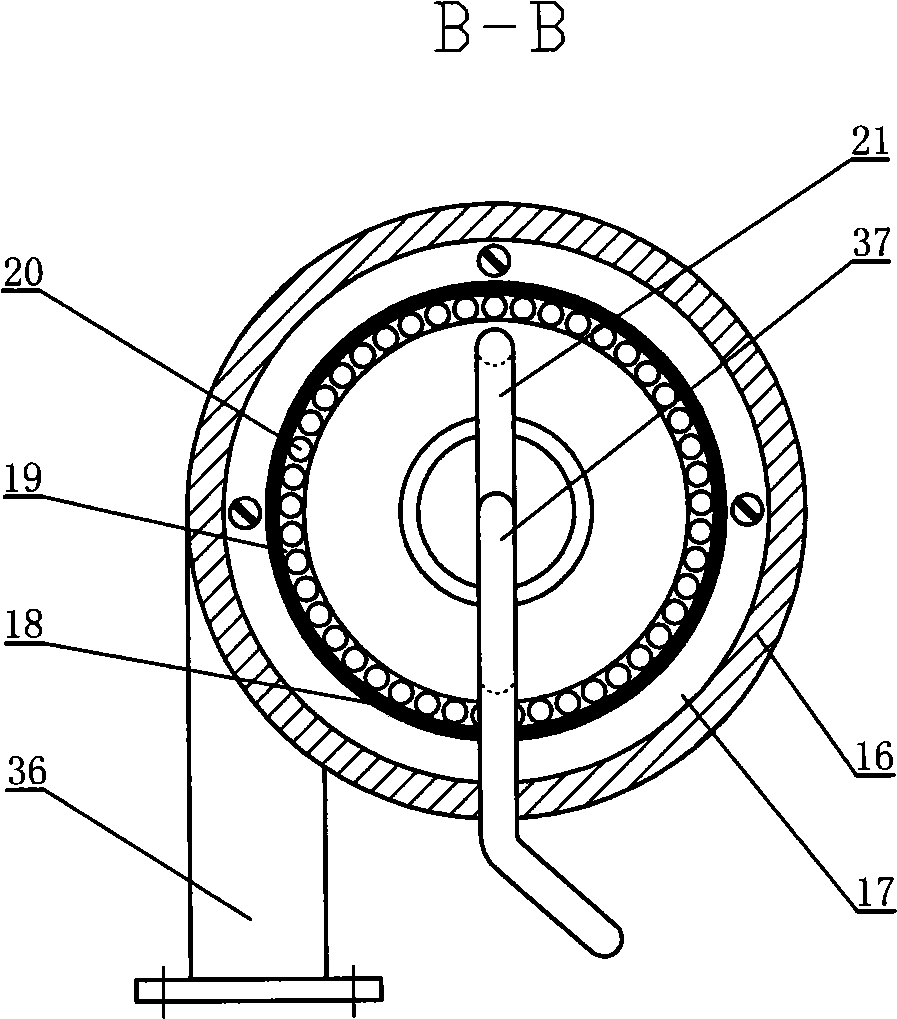

[0026] Fix the centrifuge separation orifice ring (6) with the primary filter hole (7) inside the centrifugal volute (9), and a front-end drain valve (2) is installed at the lower end of the centrifuge dirt storage chamber (5) to allow miscellaneous water to enter The tube (4) is mounted tangentially on the centrifugal volute (9). Install the seal ring (18) in the seal guide groove ring (17) at the front end of the filter element casing (16); fix the water wheel chamber seal (29) with two layers of water wheel chamber seal fixing clip rings (30) On the water wheel chamber dividing plate (31). Fix the driving water wheel (27) with the injection hole (26) on the water wheel inlet pipe (28), and then pass the water wheel water inlet pipe (28) through the water wheel chamber seal (29) and fix it to the grating On the disc (23), fix the two ends of several gratings (20) on the limit groove ring (19) and the grating fixing plate (23) respectively, and then insert the sealing ring (...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap