Solid-liquid separating device and solid-liquid separating process with filtering and air separating machine

A filtration device and solid-liquid separation technology, applied in the direction of filtration separation, separation method, filtration circuit, etc., can solve problems such as difficult tailings treatment, achieve thorough and clean dehydration, reduce hazards, and improve the quality of solid-liquid separation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

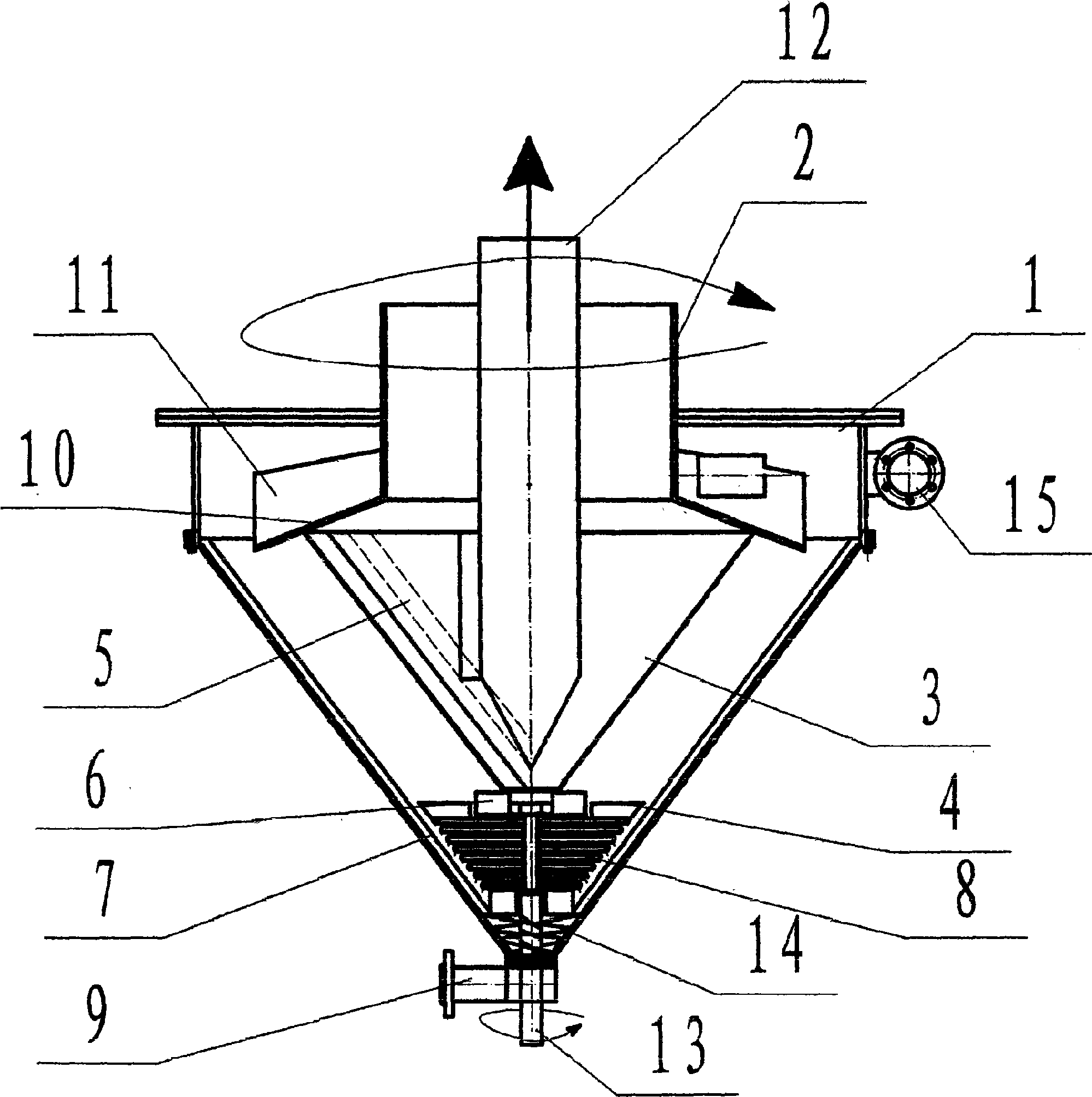

[0016] The sedimentation tank 1 is a cylindrical cone, the cylindrical part of the cylindrical cone is provided with a hollow shaft 2, the lower part of the hollow shaft 2 is provided with a diversion centrifugal device 11, and a limit cone bottom plate 10 is set below the flow diversion centrifugal device 11, and the limit cone bottom plate A filter device 3 is arranged below the filter device 3, a self-cleaning device 5 is arranged on the inner side of the cone surface of the filter device 3, a stop plate 6 is arranged under the filter device 3, and a nut is arranged under the stop plate 6; The device 7 and the inner side of the oblique cone surface of the cylindrical cone form a spiral shape; a gas separation device 8 is arranged under the swirl pressing plate 4, a hollow shaft 13 is arranged in the middle hole of the gas separation device 8, and a spiral extrusion device 14 is arranged under the gas separation device 8 A slag outlet 9 is provided at the bottom of the cylind...

Embodiment 2

[0018] As shown in Figure (1), the filter gas and separator are composed of a cylindrical conical sedimentation tank 1 and a centrifugal power vacuum shaft 2 on the upper cover, a vacuum device 12, a slag outlet in the middle of the lower part of the cone and a screw extrusion device 14 brackets. The upper rotation center hollow shaft 2 support plate of the sedimentation tank 1 is connected with a diversion centrifugal device 11 plate that can rotate around the axis and a filter device 3 mesh core connected to the bottom plate 10 of the limiting cone; the tailings entering the sedimentation tank 1 The sludge flows through the diversion centrifugal device 11, driven by the high-speed rotation of the diversion centrifugal device 11, and enters the centrifugal state, and the particles are centrifuged to the cone wall of the sedimentation tank 1; multiple slag guide devices are installed on the cone wall of the sedimentation tank 1 7 spiral guide plate, make the tailings settle qui...

Embodiment 3

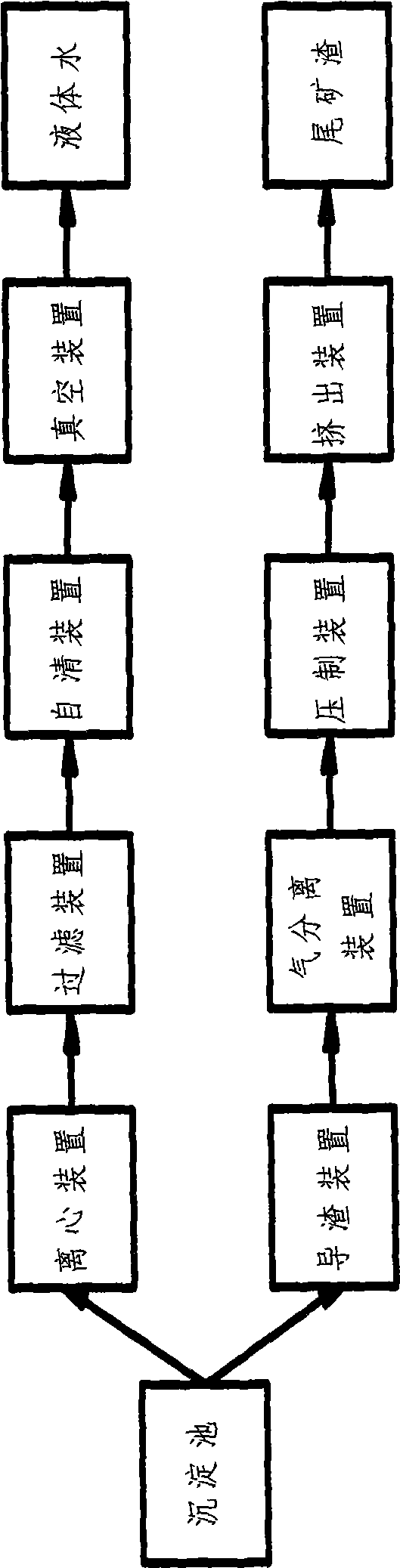

[0024] As shown in Figure (2), the process steps of solid-liquid separation using filtration and gas separator are as follows: the tailings muddy water enters the sedimentation tank 1 through the tailings inlet 15, generates centrifugal force through the diversion centrifugal device 11, and settles along the cone into the sedimentation tank 1. inside the cone. The separated water rotates to the filter element of the filter device 3, enters it after being filtered, is sucked away by the vacuum tube 12, and is discharged from the upper water outlet through power compression for recycling. The fine matter adhering to the space of the filter element of the filter device 3 is brushed off under the barrier of the plate of the self-cleaning device 5 .

[0025] The centrifuged tailings sludge quickly settles along the multiple rotating plates 7 of the cone into the chamber of the gas separation device 8, and the high-pressure gas squeezes out the water in the sediment, and the gas rep...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com